2- Base Material Standard:

GB: T2Y2 Copper Braided Wire or Copper Stranded Wire

(2.1) The joints at both ends are crimped with high-quality copper pipes or copper lug terminals;

(2.2) Single layer 1.5mm2—150mm2 (multi-layer braided wire can be customized

DIN: E-Cu58 (Number: 2.0065)

EN: Cu-ETP ( Number: CW004A)

ISO: Cu-ETP

UNS: C11000

JIS: C1100

BS: C101

Purity ≥99.99% Copper, Conductivity %IACS≥97, Hardness 80~110HV, Tensile Strength 245-345MPa, other material also can be customized.

3-Surface Treatments:

(3.1) Silver plating

(3.2) Tin plating

(3.3) Nickel plating or Resistance diffusion welding nickel sheet

(3.4) Ultrasonic cleaning

Normally plated thickness is 3μm to 12μm, but all upon customers' request.

4- Insulation Options:

(4.1) PET insulation paper (brands USA GTS, GERMANY KREMPEL, etc with white or milky white colors)

(4.2) PVC dipping (orange and green are the most popular colors)

(4.3) Epoxy powder coating (orange, green and grey are the most popular colors)

(4.4) PE heat shrink tube (orange, green, black, red are yellow are the most popular colors)

(4.5) PA66 plastic housing (white, grey etc are the most popular colors)

Flame Retardant / Fire Resistance: UL94-V-0 or upon you request;

Operating Temperature: -45ºC to +150 ºC

5- Copper Busbar Resistance: ≤0.00001Ω

6- Copper Busbar load voltage 3500VDC to 5000VDC and current 100A to 2000A

7- Copper Busbar Assembly Fixtures: USA PEM stainless nuts, studs, standoffs, screws, etc

8- Free Samples:1-10pcs is allowed

9- Lead Time:Orders 7-10days,Samples 10-20days(including the tooling/die production of Copper Stamped Part);

10- Packing: pearl cotton/blister box inside and carton/pallet outside

11- Certifications: ISO9001, IATF16949, RoHS, REACH, etc.

12- Production Capacity: 50,000,000 pcs/month

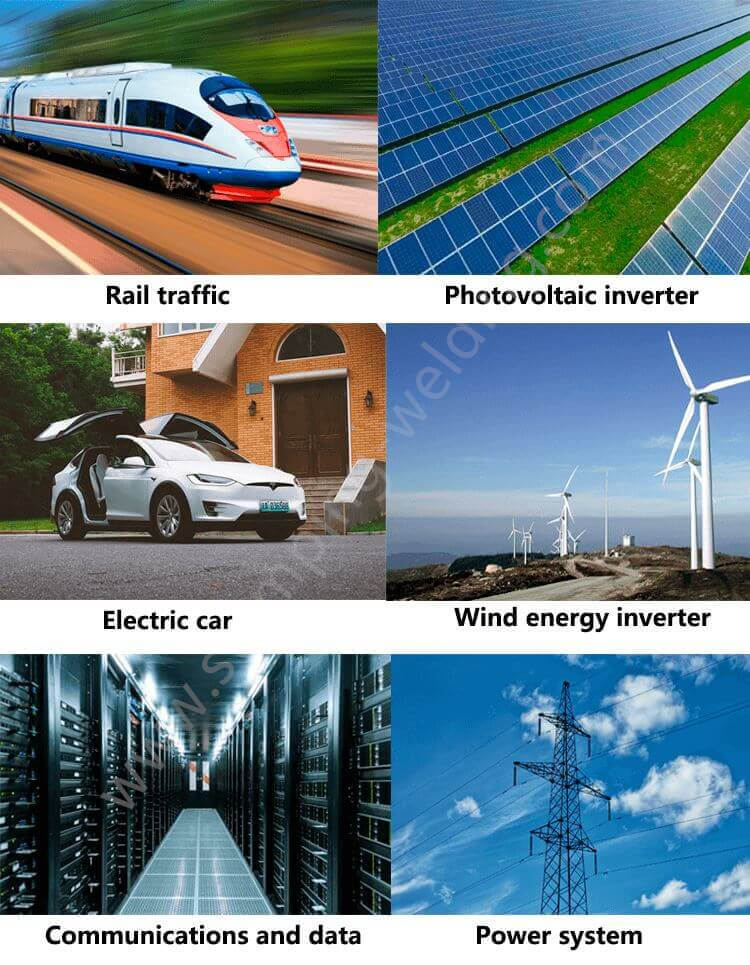

13- Applications: film capacitors for new energy electric vehicles and hybrid vehicles, new energy vehicle battery packs, new energy photovoltaic energy storage, power appliances, distribution cabinets, rail transit, cloud server uninterruptible power supplies and other power systems.

Copper stranded wire and Copper flexible busbars are both components used in electrical systems, often for conducting electricity within various applications. Here's a breakdown of each:

Copper Stranded Wire:

1.1 Composition: Copper stranded wire is made up of multiple thin strands of copper wire twisted or braided together. The stranding increases flexibility and conductivity compared to solid copper wire.

1.2. Flexibility: Due to its stranded construction, copper stranded wire is highly flexible, making it suitable for applications where bending and movement are required.

1.3. Conductivity: Copper Stranded Wire is an excellent conductor of electricity, and the stranding of wires further enhances conductivity by increasing the surface area for electron flow.

1.4. Applications: Copper Wire Twisted is used in various applications including electrical wiring in buildings, automotive wiring, power distribution, and industrial machinery where flexibility and conductivity are essential.

Flexible Busbar:

2.1. Composition: A flexible busbar is typically made of a strip or multiple strips of copper or aluminum that are insulated and can bend or flex.

2.2. Flexibility: Unlike rigid busbars, flexible busbars can bend and conform to the shape of the application, making them suitable for installations where space is limited or where movement and vibration occur.

2.3. Conductivity: Similar to copper stranded wire, flexible busbars offer high conductivity due to their copper composition. They are capable of carrying high currents efficiently.

2.4. Applications: Flexible Copper busbars are commonly used in switchgear, panel boards, battery connections, and other power distribution systems where space constraints or dynamic environments necessitate flexibility.

Differences:

3.1 Form: Copper stranded wire typically comes in the form of individual wires twisted or braided together, while flexible busbars are usually in the form of flat strips with insulation.

3.2 Application: Copper stranded wire is often used for point-to-point connections and wiring, while flexible busbars are used for distributing power within systems and components.

3.3 Flexibility Range: Flexible busbars offer a broader range of flexibility and can be bent and shaped more extensively compared to copper stranded wire.

In summary, while both copper stranded wire and flexible busbars serve as conductors in electrical systems, they differ in form, application, and flexibility range, with each being suited to specific electrical requirements and installation scenarios.

Contact Information:

Ms.Tina Tian (Sales Manager&Technology Engineer)

Xiamen Apollo Stamping Welding Technology Co., Ltd

Apollo Electronic Components (Xiamen) Co.,Ltd

Add: No.2, Chengyi North Road, Jimei Software Park, Jimei District, Xiamen City, Fujian Province, China, 361022

Mob/WhatsApp/WeChat: 0086-15985814329

Email: tina@stamping-welding.com

Web: www.stamping-welding.com , www.china-electronic-components.com

Since 2010, professional in Metal Stamping & Welding Solutions for New Energy EV & PV Fuse, Battery, Capactior, Relay, Switch, ect!