Xiamen Apollo Stamping Welding Technology Co., LTD is one branch of our group Apollo Electronic Components (Xiamen) Co.,Ltd,which has focused on top quality Aluminum Case For Lithium Ion Battery Cell, Copper End Cap, Fuse Terminal Contact,EV (ELECTRICAL VEHICLE) Film Capacitor BusBar,PV (SOLAR POWER) Inverter BusBar,Laminated BusBar and other electronic products for over 18 years in China. We started as a small operation, but now have become one of the leading suppliers in EV and PV industry in China.

Today, we have been one of the top producers of electronic components which mainly concentrated in new energy, solar energy, electric vehicles, electric power, contact, precision relays, precision electronic switches and other products.More than 18 years of metal stamping and welding service experience, cooperated with electric fuse manufacturer,film capacitor manufacturer,relay manufacturer etc for many years, not only to provide customers with qualified products, but also to provide customers with product solutions and technical process experience.

Apollo is located in the China port city-Xiamen. As a global supplier in the component for electric fuse,busbar,stain-less steel shell and aluminum cans for battery and other EV electronic products, Apollo is to create added value for customers around the world.

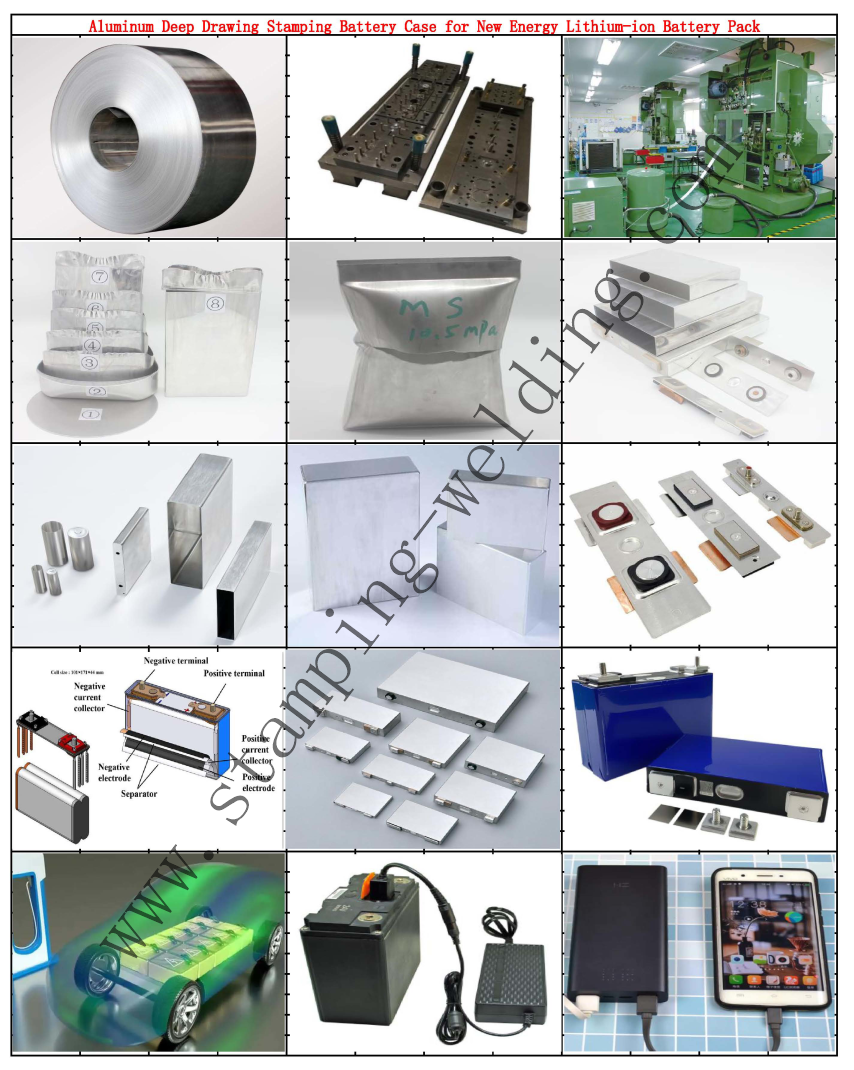

Ion Cell Charger Aluminum Shell ,as the protective shell of the power battery, the power battery shell is also the key factor to determine the quality of the power battery.Electric vehicle power battery shell generally uses #3003 Aluminum Alloy material, because this material is easy to process, high temperature corrosion resistance, good heat transfer and electrical conductivity.

1-Product Name: Lithium Batteries Square Aluminum Case;

2-Packing: Plastic Blister inside and carton/pallet outside;

3-Applications: EV/HEV,PV,UPS,Communication,Industrial Power Energy Storage,Web Server,etc;

4-Certifications: ISO9001,IATF16949,RoHS,Reach,etc;

5-Samples: Allowed,made by Laser welding or punching machine;

6-Lead Time: 15-20days;

7-Orders: MOQ 1,000pcs/item,made by stamping die;

8-Lead time: 20-30days(die&products);

9-Shipping Methods:By Air/Sea/Train,Express(DHL/UPS/TNT/FEDEX,etc);

10-Payment Items: 30% deposit and balance before shipment by Bank T/T or L/C at sight;

11-Main Products: Metal Stamping and Welding Solutions for

(1)Battery Pack Aluminum Shell;

(2)Fuse Copper and Brass Cap/Contact/Knife;

(3)Copper Busbar;

(4)Power Capacitor Steel/Aluminum Cans,etc for new energy.

12-Our products Aluminum Battery Case features:

(1)The lithium battery shell inhibits the battery polarization, reduces the thermal effect, improves the rate performance;

(2)Reduce the battery internal resistance, and significantly reduce the cycle process of dynamic internal resistance increase;

(3)Lithium battery shell to improve consistency, increase battery cycle life;

(4)Improve the adhesion between the active substance and the collector, reduce the manufacturing cost of the pole piece;

(5)Lithium battery shell to protect the collection fluid is not corroded by electrolyte;

(6)Improve the high and low temperature performance of lithium battery, improve the processing performance of lithium iron phosphate and lithium titanate materials.

13-Our Advantages:

(1)With a daily output of 50,000 sets of power and energy storage lithium battery structural parts, 5 million sets of PACK soft connection/year and 150,000 sets of automotive filters/year, independent research and development, manufacturing molds;

(2)Std-300s automatic power punch, adjustable precision up to 0.1mm, safe, convenient and reliable;

(3)Automatic ultrasonic cleaning machine: die punch adopts water circulation cooling system to ensure that the temperature of die punch is moderate and the product is not deformed;

(4)The lower die is pushed out by cylinder to ensure the bottom of the product is smooth and beautiful.