Xiamen Apollo Stamping Welding Technology Co., LTD is one branch of our group Apollo Electronic Components (Xiamen) Co.,Ltd,which has focused on top quality Copper End Cap,Fuse Terminal Contact,EV (ELECTRICAL VEHICLE) Film Capacitor BusBar,PV (SOLAR POWER) Inverter BusBar,Laminated BusBar and other electronic products for over 18 years in China. We started as a small operation, but now have become one of the leading suppliers in EV and PV industry in China.

Today, we have been one of the top producers of electronic components which mainly concentrated in new energy, solar energy, electric vehicles, electric power, contact, precision relays, precision electronic switches and other products.More than 18 years of metal stamping and welding service experience, cooperated with electric fuse manufacturer,film capacitor manufacturer,relay manufacturer etc for many years, not only to provide customers with qualified products, but also to provide customers with product solutions and technical process experience.

Apollo is located in the China port city-Xiamen. As a global supplier in the component for electric fuse, busbar, stain-less steel shelland aluminum cans for battery and other EV electronic products, Apollo is to create added value for customers around the world.

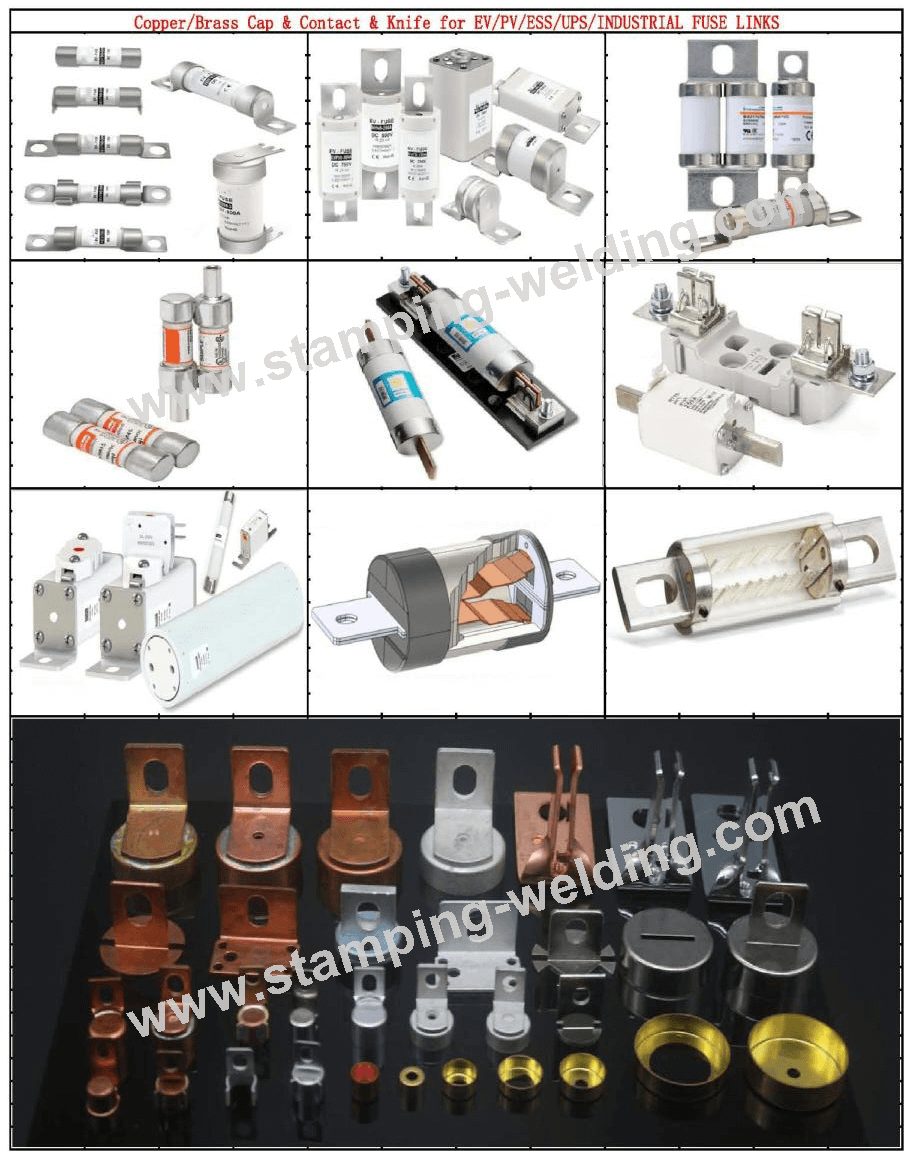

1-Product Name: Copper Outer Cap,Inner Brass Cap,Fuse Contact Cap Welding Assembly

2-Dimensions: OEM/ODM as your drawing

3-Material:

(1)99.99% Red Copper T2Y2,%IACS≥97,HV:80~110s;

(2)Brass H59/H62/H65/H68 (almost use H65), HV:100~130s

4-Processing: Tooling--Stamping--Riveting--Resistance Tin/Silver Brazing/Laser Welding--Plating

5-Surface treatments for finished products,usually the plated thickness would be lead-free fog tin plating 5-8μ, bright tin plating 5-8μ, silver plated 3-5 micron:

(1)Silver plated;

(2)Nickel plated;

(3)Tin-plated;

(4)Copper plated;

(5)Ultrasonic cleaned and passivation,etc.

6-Supply Methods:

(1)Fuse Outer Cap;

(2)Fuse Inner Cap;

(3)Fuse Outer Cap and Contact Welded Assembly Set;

(4)NH Fuse Knife;

(5)Fuse Holder Copper Knife,etc.

7-Packing: Plastic inside and carton/pallet outside

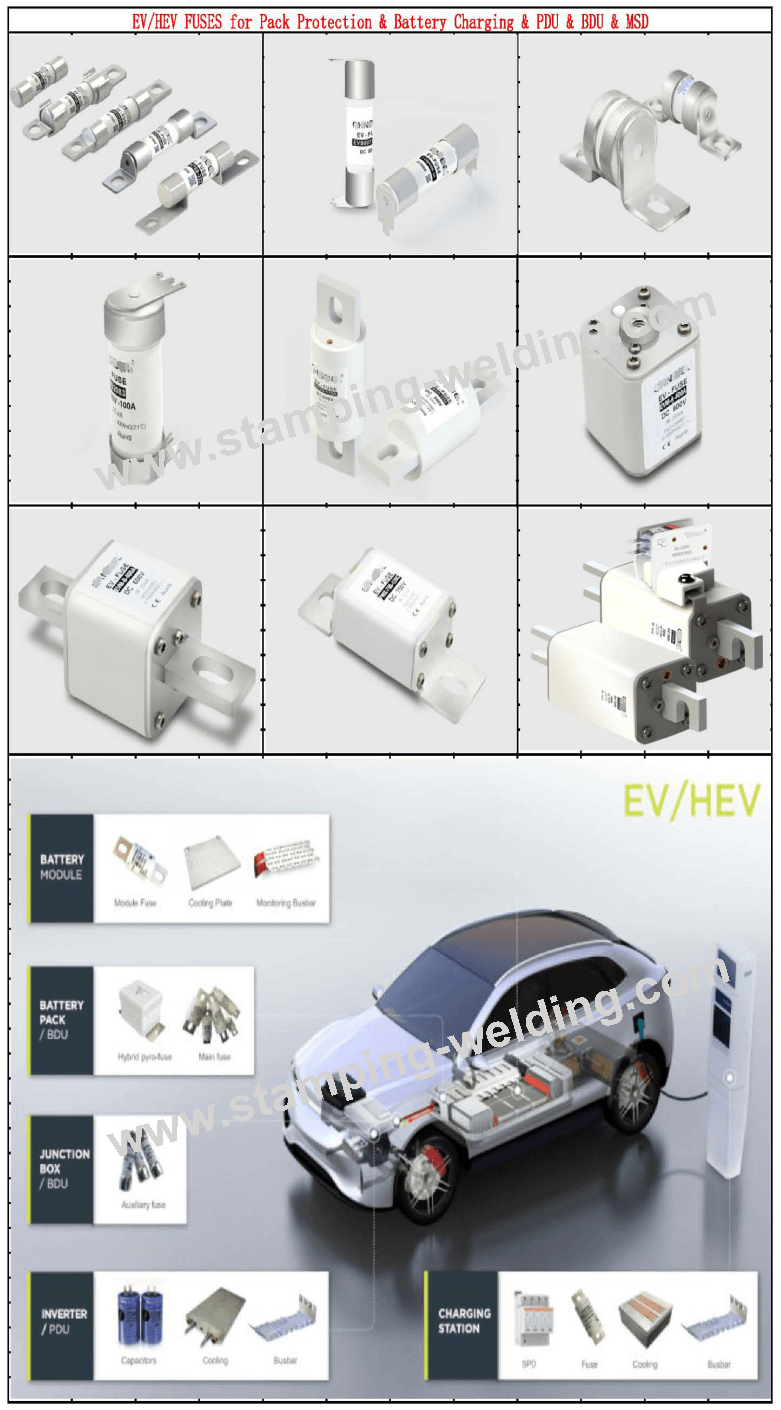

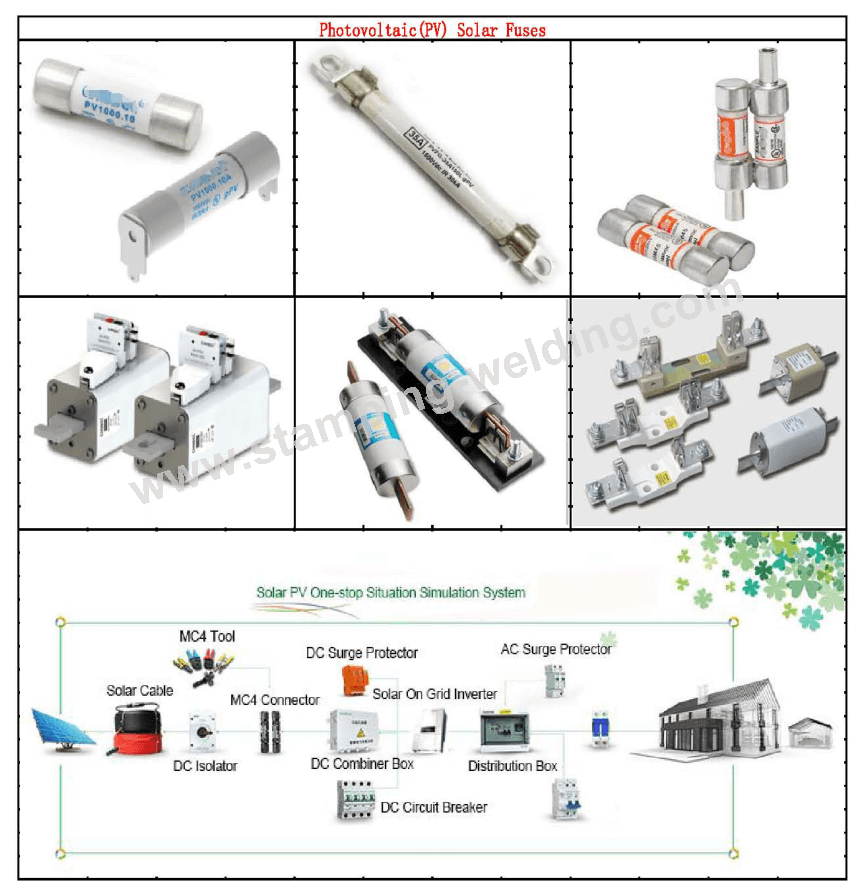

8-Applications: EV/HEV,PV,UPS,Communication,Industrial Power,Web Server,Rail Transit,etc.

9-Certifications: ISO9001,IATF16949,RoHS,Reach,etc.

10-Samples: Allowed,made by Laser cutting or CNC punching machine,

11-Lead Time: 5-10days.

12-Orders: MOQ 1,000pcs/item,made by stamping die,

13-Lead time: 20-30days(die&products).

14-Shipping Methods:By Air/Sea/Train,Express(DHL/UPS/TNT/FEDEX,etc)

15-Payment Items: 30% deposit and balance before shipment by Bank T/T or L/C at sight.

16-Main Products: Metal Stamping and Welding Solutions for

(1)Fuse Copper and Brass Cap/Contact/Knife;

(2)Copper Busbar;

(3)Battery Pack Aluminum Shell;

(4)Power Capacitor Steel/Aluminum Cans,etc for new energy.

17-Our products' features:

(1)Our Brass or Copper raw material for fuse cap with good electrical conductivity and thermal conductivity, good corrosion-resistance;

(2)High speed precision stamping, high dimensional consistency and stability;

(3)The brass or copper end cap is cut by the rotary cutting process, and the wrapping is free of burrs.

(4)Electroless Plating Bright Tin/Fog Tin/Nickel/Silver Ag, corrosion resistance and long service life.

(6)This Fusible Link Outer End Cap And Terminal are used for bolted connection low-voltage fuse, high-voltage fuse, fast speed fuse, fuse links.It is suitable for electric vehicles industry, can be used as electric vehicle energy storage, power battery, energy storage capacitor ,drive electric power systems, power transformation system etc.

The cap is made of high quality T2 red copper belt with high purity 99.97%. This copper is corrosion resistant and easy to weld.The knife-shaped terminal is made of H65 brass belt with good electrical performance and high strength.The H65 brass terminals are produced in one tooling which accomplish the processing of punching, bending, forming and auto assembly with T2 outer caps.So the sizes of product are stable and also with high efficiency and high production.

Our Advantages:

1-Ex-works: China factory direct supply,we earn 5% profit and give the benefit to our customers;

2-Lead Time: 10-20days for samples/mass orders;

3-Successful Experience: Long-term cooperation with famous brands customers ,we can supply Cost-reduction and Latest Trending Technology;

4-Group Power: Own Stamping Die,Stamping and Drawing Machines,In-die Riveting,Robot Laser Welding,Resistance Tin/Silver Brazing,etc;

5-Ready free samples.

6-Lead time 7-10 days for samples and 7-15 days for orders;

7-We have all kinds of general specifications of the inner cap, outer cap molds;

8-We have welding laboratory, can provide customers with a variety of welding process validation, such as tin welding, resistance welding, laser welding, TIG welding, high frequency welding, argon arc welding, micro arc welding and so on.