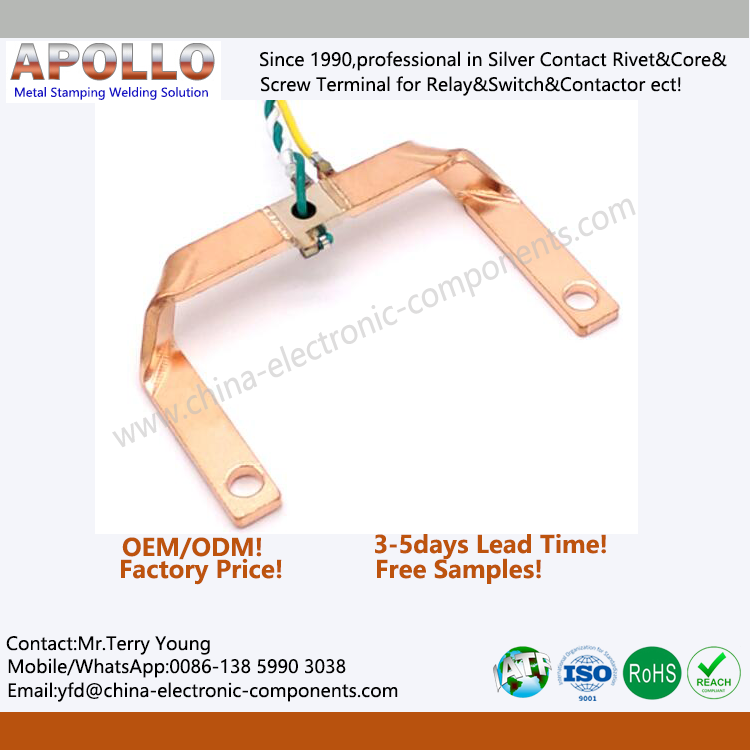

1-Product: 6J13 Manganese Copper Shunt for Magnetic Latching Relay

2-Material: T2Y2 Pure Copper+Manganese Copper+Copper Terminal (if need)

3-Resistance value tolerance: ± 5%

4-Process: EBW(Electron beam welding),Stamping,Spot Welding

5-Aging: 10 hours under 120 deg

6-Power loss: <50 milli watt

7-Termination: Integrated lead wires are available

8-Application: Work in all kinds of electrical meter as power measurer,like Prepayment Energy Meter,AMR System,Automatic Control System,Compound Switch etc.

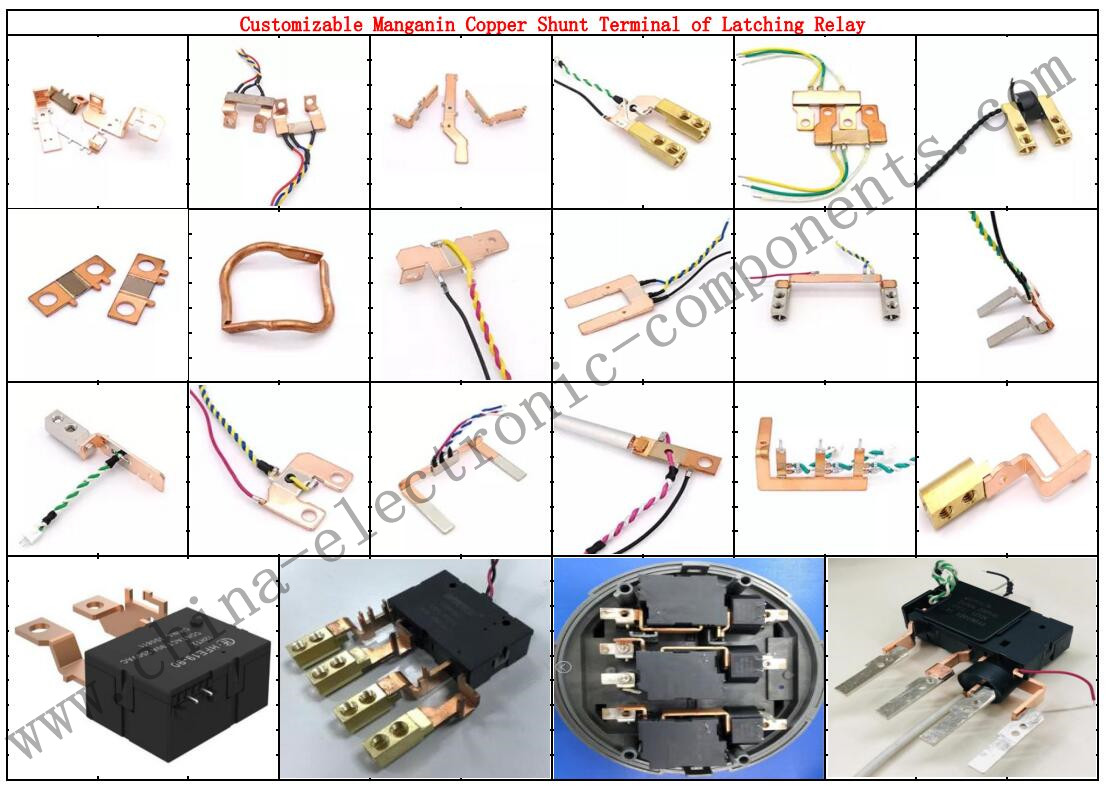

9-Customized designs are available against customer's Latching Relay Manganin Shunt drawings/samples.

Product features of Manganese Copper Shunts

1-Ambient temperature: -20~80°C. 1.2 Relative humidity: up to 95%, 40°C.

2-Insulation resistance: At room temperature, the insulation resistance of the sampling wire and heat shrinkable sleeve used in the product E-beam Welding Shunt is not less than 100MΩ; after undergoing the steady-state thermal test, the insulation resistance is not less than 1MΩ.

3-Medium withstand voltage: Under normal conditions, the sampling line and heat shrinkable tube used in the product EBW (Electron Beam Welding) Manganin Shunt should be able to withstand the medium withstand voltage of 500VAC (AC RMS) for 1 minute, and there should be no breakdown, arcing and flashover.

4-Temperature coefficient: 0.4×10-6/°C

5-Temperature rise: When the rated maximum current is applied to the product Manganese Copper Shunts, the temperature rise should not exceed 60°C.

6-Welding strength: The welding strength of the connecting piece and Spot Welding for Manganin Shunt Resistor should be able to withstand the destructive inspection of bending the connecting piece with a force of 200N. At this time, the welding surface should not be de-soldered or cracked; the welding strength of the sampling line should be able to withstand 50N Tensile test, no desoldering or disconnection for the Electric Meters Manganin Shunt.

Working principle and characteristics of Electron Beam Welding of Copper Manganin Shunt of magnetic latching relay

The working principle of electron beam welding is: under vacuum conditions, the electron beam emitted from the electron gun is accelerated by a high voltage (usually 20-300kV), and is focused into an electron beam with high energy density through an electromagnetic lens. When the electron beam bombards the workpiece Energy Meter Shunts, the kinetic energy of the electrons is converted into heat energy, and the local temperature of the welding zone can rise sharply to more than 6000 ℃. The workpiece material of Copper Manganin Shunt is partially melted to achieve welding.

①High heating power density

The power of the electron beam is the product Electricity Meter Shunt of the beam current and its accelerating voltage, and the power of the electron beam can range from tens of kW to more than 100 kW. The power of the electron beam spot (or focus) can reach 106-108W/cm2, which is about 100-1000 times higher than the arc power density. Due to the high power density, concentrated heating, high thermal efficiency, and small heat input required to form the same weld joint, the electron beam is suitable for the welding of refractory metals and metal materials with strong thermal sensitivity. Moreover, the deformation after welding is small, and the finished parts Manganin Shunt Resistor for Current Measurement can be welded.

②The welding seam penetration and penetration ratio (that is, the aspect ratio) is large

The penetration-width ratio of ordinary arc welding is difficult to exceed 2. The ratio of electron beam welding can be as high as 20 or more, so electron beam welding can use high-power electron beams to perform single-sided welding of large-thickness steel plates without grooves. Thus greatly improving the technical and economic indicators of thick plate welding. At present, the maximum thickness of steel plates Customizable Copper Manganin Shunt Resistor for electron beam single-sided welding exceeds 100 mm, while the maximum thickness of electron beam welding for aluminum alloys has exceeded 300 mm.

③The atmosphere around the molten pool is of high purity

Because electron beam welding is carried out in a vacuum environment with a vacuum degree of 10-2 to 10-4Pa. The amount of oxygen and nitrogen present in the residual gas is hundreds of times less than that of 99.99% pure argon gas, so electron beam welding does not have the problem of oxidation pollution of weld metal Shunt Assembly. Therefore, it is especially suitable for welding metals with strong chemical activity, high purity and easy to be polluted by the atmosphere (oxidation) at the melting temperature. Such as aluminum, titanium, zirconium, molybdenum, high-strength steel, high-alloy steel and stainless steel. This welding method is also suitable for high melting point metals and can be used for tungsten-tungsten welding.

The structure of the Magnetic Latching Relay

The magnetic latching relay is divided into two layers, the upper layer is the electromagnetic system, and the lower layer is the Silver Electric Contact system. The electromagnetic system adopts a flat direct-acting magnetic latching magnetic circuit system, which includes a Terminal Block Manganin Shunt, a coil, an Electrician pure iron armature, an Electrician pure iron core, and a mounting plate. The Prepayment Meter Shunts are located on the mounting plate. In the center, coils are installed on both sides of the Cable Wire Shunt Resistor, a U-shaped iron core is arranged above the coil, and the armature is positioned between the iron cores to form an annular structure, which can be controlled by a Primary Wire Manganin Shunt field. Both ends of the mounting plate are located beside the U-shaped bottom of the iron core, and a pure iron plate is also installed to prevent the interference of external Braze Welding Shunt Resistance fields (for Energy Meter ).

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !