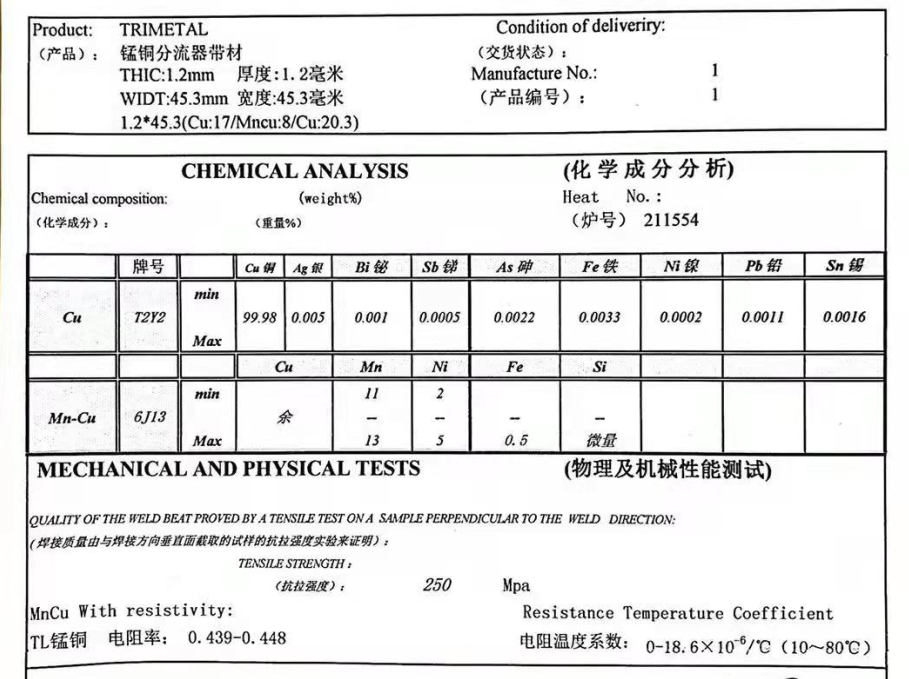

2-Material: T2Y2 Pure Copper+Manganese Copper+Copper Terminal (if need)

3-Resistance value tolerance: ± 5%

4-Process: EBW(Electron beam welding),Stamping,Spot Welding

5-Aging: 10 hours under 120 deg

6-Power loss: <50 milli watt

7-Termination: Integrated lead wires are available

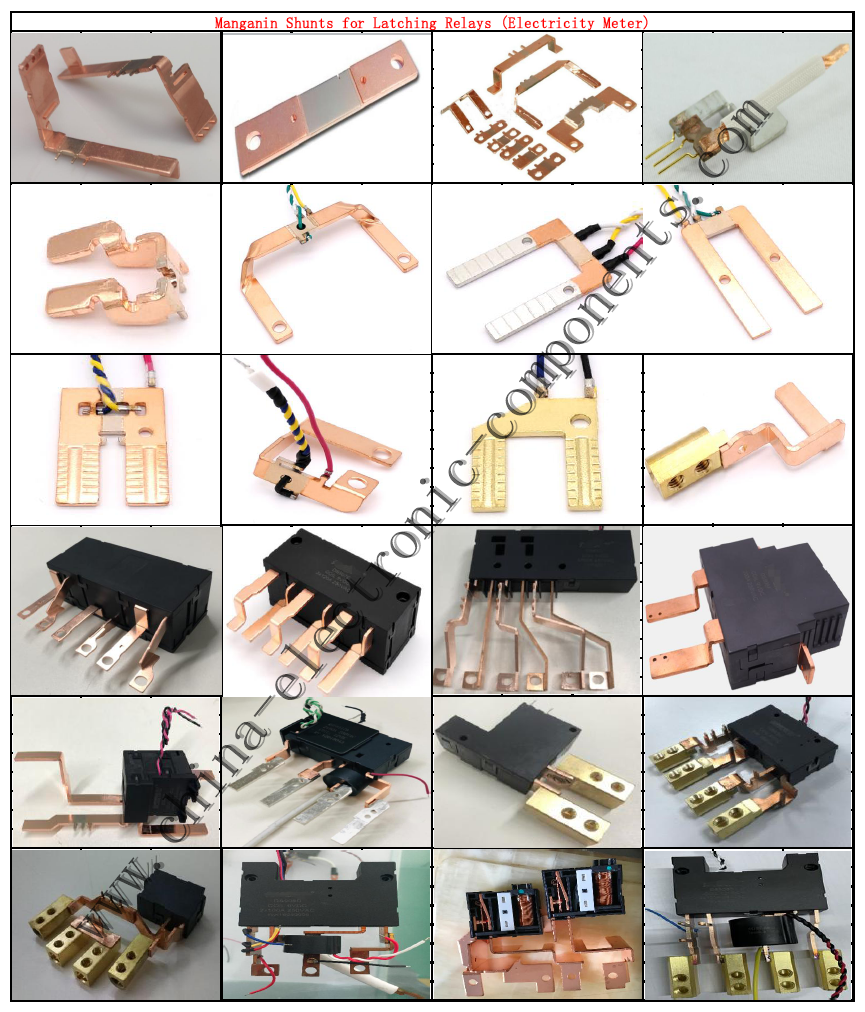

8-Application: Work in all kinds of electrical meter as power measurer,like Prepayment Energy Meter,AMR System,Automatic Control System,Compound Switch etc.

9-Customized designs are available against customer's Latching Relay Manganin Shunt drawings/samples.

Product features of Manganese Copper Shunts

1-Ambient temperature: -20~80°C. 1.2 Relative humidity: up to 95%, 40°C.

2-Insulation resistance: At room temperature, the insulation resistance of the sampling wire and heat shrinkable sleeve used in the product E-beam Welding Shunt is not less than 100MΩ; after undergoing the steady-state thermal test, the insulation resistance is not less than 1MΩ.

3-Medium withstand voltage: Under normal conditions, the sampling line and heat shrinkable tube used in the product EBW (Electron Beam Welding) Manganin Shunt should be able to withstand the medium withstand voltage of 500VAC (AC RMS) for 1 minute, and there should be no breakdown, arcing and flashover.

4-Temperature coefficient: 0.4×10-6/°C

5-Temperature rise: When the rated maximum current is applied to the product Manganese Copper Shunts, the temperature rise should not exceed 60°C.

6-Welding strength: The welding strength of the connecting piece and Spot Welding for Manganin Shunt Resistor should be able to withstand the destructive inspection of bending the connecting piece with a force of 200N. At this time, the welding surface should not be de-soldered or cracked; the welding strength of the sampling line should be able to withstand 50N Tensile test, no desoldering or disconnection for the Electric Meters Manganin Shunt.

https://china-electronic-components.com/product1_52_0_63.html

https://china-electronic-components.com/product1_52_0_63.html

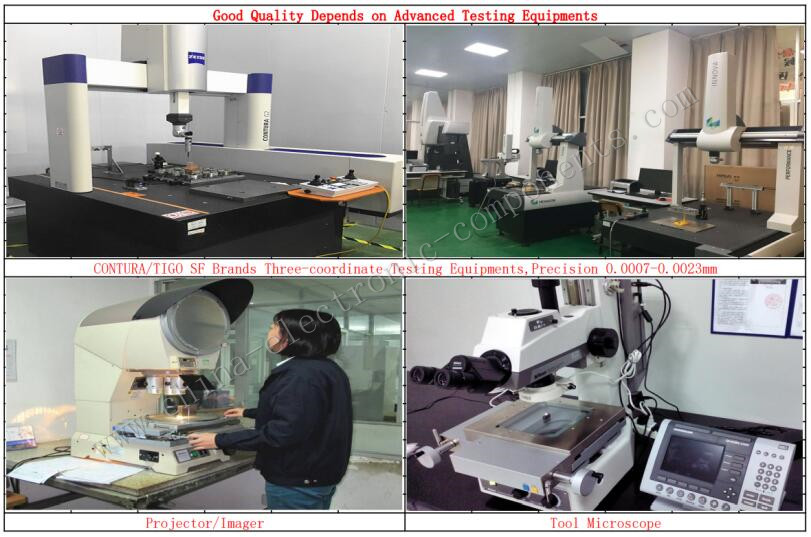

Characteristics of Electron Beam Welding of Manganese Copper Shunts of Magnetic Latching Relays

1) The energy density of electron beam welding is high, and it can weld welds that are difficult to achieve by ordinary arc welding;

2) Electron beam welding is carried out in vacuum, the chemical composition of the weld is stable and pure, the joint strength is high, and the weld quality is high;

3) The electron beam welding speed is fast, the heat affected zone is small, and the welding thermal deformation is small;

4) Electron beam welding is suitable for welding almost all metal materials, especially for Copper Alloy Shunt and aluminum welding;

5) Electron beam welding can obtain welds with a large aspect ratio (20: 1 ~ 50: 1), and when welding thick parts, it can be formed at one time without opening the groove;

6) Electron beam welding combines computer technology to achieve precise control of process parameters and fully automate the welding process.

Electron beam welding technology is currently the fastest growing and most widely used electron beam technology.

We can supply samples of Latching Relay Manganin Shunt

We are a professional manufacturer of Manganese Copper Shunts for magnetic latching relays (also known as manganese-copper sampling resistors) for 15 years. The product has stable resistance value and good performance, and constantly develops and develops new structures. Especially in recent years, there are more and more embedded manganin resistors.

The Cable Wire Shunt Resistor produced by our factory have various specifications: 120 μΩ, 175 μΩ, 200 μΩ, 250 μΩ, 300 μΩ, 350 μΩ, 400 μΩ, 500 μΩ, 600 μΩ, 800 μΩ, 1000 μΩ and other resistance values, the resistance tolerance is ±5% , the hole distance and hole diameter are determined by the customer, and are suitable for various electric energy meters of different currents.

What is a Latching Relay ?

Magnetic latching relay is a new type of relay developed in recent years, and it is also an automatic switch. Like other electromagnetic relays, it automatically switches on and off the circuit. The difference is that the normally closed or normally open state of the magnetic latching relay is completely dependent on the action of the Permanent Magnet Shunt, and the switching of its switching state is triggered by a pulsed electrical signal of a certain width.

Magnetic latching relays are divided into single-phase and three-phase. According to relevant information, the Electric Silver Contact switching current of magnetic latching relays on the market can reach up to 150A; the control coil voltage is divided into DC9V, DC12V and so on. The general electrical life is 10,000 times; the mechanical life is 1,000,000 times; the Electrical SIlver Contact Rivet voltage drop of the contact is less than 100mV. Therefore, Brass Terminal Lead Shunt Resistor of latching relay has the characteristics of power saving, stable performance, small size, large carrying capacity, and superior performance than general electromagnetic relays.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !