What aspects determine the quality of advanced manufacturing technology for stamping and injection molds?

The application of advanced mold manufacturing technology has changed the traditional molding technology that the mold quality depends on human factors and is difficult to control, making the mold quality dependent on physical and chemical factors, the overall level is easy to control, and the mold reproduction ability is strong.

1- High Speed Milling

Ordinary milling uses low feed speed and large cutting parameters, while high-speed milling uses high feed speed and small cutting parameters. Compared with ordinary milling, high-speed milling has the following characteristics:

(1)High-efficiency High-speed milling spindle speed is generally 15000r/min ~ 40000r/min, up to 100000r/min. When cutting steel, its cutting speed is about 400m/min, which is 5 to 10 times higher than that of traditional milling; when machining mold cavity, its efficiency is compared with that of traditional machining methods (traditional milling, EDM, etc.). Increase 4 to 5 times.

(2)High precision The machining accuracy of high-speed milling is generally 10 μm, and some are even higher.

(3)High surface quality Because the temperature rise of the workpiece is small (about 3°C) during high-speed milling, there is no metamorphic layer and micro-cracks on the surface, and the thermal deformation is also small. The best surface roughness Ra is less than 1μm, which reduces the workload of subsequent grinding and polishing.

(4)It can process high-hard materials. It can mill 50-54HRC steel, and the maximum hardness of milling can reach 60HRC.

In view of the above advantages of high-speed machining, high-speed machining is being widely used in mold manufacturing, and gradually replaces part of grinding and electrical machining.

2- EDM milling

EDM milling (also known as EDM) is a major development in EDM technology, a new technology that replaces the traditional machining of mold cavities with forming electrodes. Like CNC milling, EDM uses high-speed rotating rod electrodes to contour the workpiece in 2D or 3D without the need to manufacture complex, expensive shaped electrodes. The EDSCAN8E EDM machine tool launched by Japan's Mitsubishi Corporation is equipped with an electrode loss automatic compensation system, a CAD/CAM integrated system, an online automatic measurement system and a dynamic simulation system, which reflects the level of today's EDM machine tools.

3-Slow wire cutting technology

The development level of CNC wire cutting technology has been quite high, the function is quite complete, and the degree of automation has reached the level of unattended operation. The maximum cutting speed has reached 300mm2/min, the machining accuracy can reach ±1.5μm, and the machining surface roughness Ra0.1~0.2μm. The development of wire cutting technology with a diameter of 0.03~0.1mm can realize the one-time cutting of the concave and convex die, and can perform the cutting process of 0.04mm narrow groove and 0.02mm radius inner fillet. The taper cutting technology has been able to carry out precision machining with a taper of more than 30°.

4-Grinding and polishing technology

Grinding and polishing are widely used in precision mold processing due to their high precision, good surface quality, and low surface roughness values. Precision mold manufacturing widely uses advanced equipment and technologies such as CNC forming grinders, CNC optical curve grinders, CNC continuous trajectory coordinate grinders and automatic polishing machines.

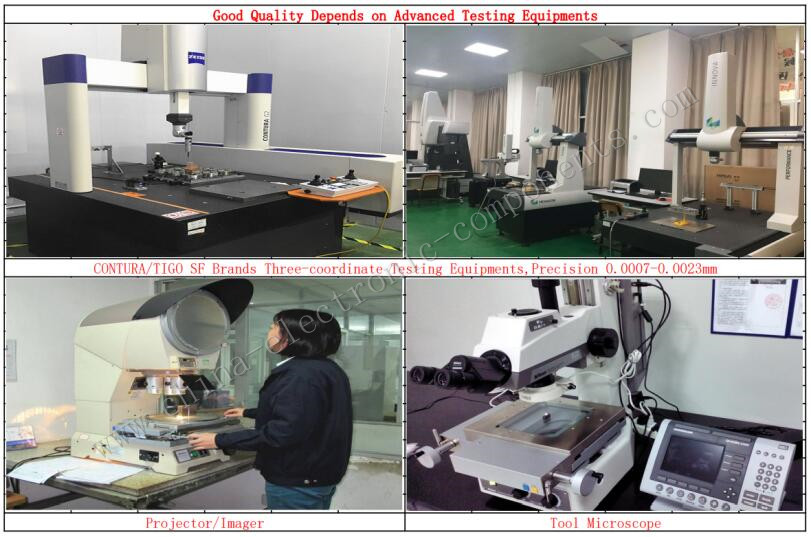

5-CNC measurement

The complex product structure will inevitably lead to the complex shape of the mold parts. Traditional geometric detection methods have been unable to adapt to the production of molds. Modern mold manufacturing has widely used three-coordinate numerical control measuring machines to measure the geometric quantities of mold parts, and great progress has been made in the detection methods of mold processing. In addition to measuring the data of complex curved surfaces with high precision, the three-coordinate numerical control measuring machine has good temperature compensation device, reliable anti-vibration protection ability, strict dust removal measures and simple operation steps, which makes on-site automatic detection possible.

What’s the basic performance requirements of steel for plastic mold?

Plastic mold is a tool that is matched with plastic molding machines in the plastic processing industry to give plastic products a complete configuration and precise size. Due to the variety of plastic varieties and processing methods, and the complex and simple structures of Injection Mold machines and plastic products, the types and structures of Plastic Molding are also diverse.

The working conditions of Plastic Injection Molding are different from those of cold stamping dies. Generally, they must work at 150°C-200°C. In addition to a certain pressure, they must also be affected by temperature. According to the different use conditions and processing methods of Custom Plastic Molding, the basic performance requirements of steel for Plastic Mold Maker are roughly summarized as follows:

1. Sufficient surface hardness and wear resistance

The hardness of the Injection Tooling is usually below 50-60HRC, and the heat-treated mold should have sufficient surface hardness to ensure that the Injection Molded Parts has sufficient rigidity. During the operation of the Plastic Injection Molding, due to the filling and flow of the plastic, it has to bear large compressive stress and frictional force. The wear resistance of the mold depends on the chemical composition of the steel and the hardness of heat treatment, so increasing the hardness of the Plastic Molding is beneficial to improve its wear resistance.

2. Excellent machinability

Most plastic molding molds require certain cutting processing and fitter repair in addition to EMD processing. In order to prolong the service life of cutting tools, improve cutting performance, and reduce surface roughness, the hardness of plastic mold steel must be appropriate.

3. Good polishing performance

High-quality plastic products require a small roughness value on the surface of the cavity. For example, the surface roughness value of the Plastic Injection Molding cavity is required to be less than Ra0.1~0.25, and the optical surface requires Ra<0.01nm, and the cavity must be polished to reduce the surface roughness value. The steel selected for this purpose requires less material impurities, fine and uniform structure, no fiber orientation, and no pitting or orange peel defects during polishing.

4. Good thermal stability

The shape of the parts of the plastic injection mold is often complicated, and it is difficult to process after quenching. Therefore, it should be selected as far as possible with good thermal stability. When the Plastic Injection is formed and processed after heat treatment, the linear expansion coefficient is small, the heat treatment deformation is small, and the dimensional change caused by the temperature difference. The rate is small, the metallographic structure and mold size are stable, and the processing can be reduced or no longer required to ensure the mold size accuracy and surface roughness requirements.

45 and 50 grades of carbon steel have certain strength and wear resistance, and are mostly used for Custom Plastic Molding base materials after quenching and tempering. High carbon tool steel and low alloy tool steel have high strength and wear resistance after heat treatment, and are mostly used for forming parts. However, high carbon tool steel is only suitable for the manufacture of formed parts with small size and simple shape due to its large deformation during heat treatment.

With the development of the plastics industry, the complexity and precision of plastic products are becoming more and more demanding, and higher requirements are also placed on Plastic Injection Molding materials. For the manufacture of complex, precise and corrosion-resistant plastic molds, pre-hardened steels (such as PMS), corrosion-resistant steels (such as PCR) and low-carbon maraging steels (such as 18Ni-250) can be used, all of which have better performance. Machining, heat treating and polishing properties and high strength.

In addition, when selecting materials, it is necessary to consider preventing scratches and gluing. If there is relative movement between the two surfaces, try to avoid selecting Plastic Injection materials with the same structure. In special cases, one side can be plated or nitrided to make the two sides different. surface structure.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

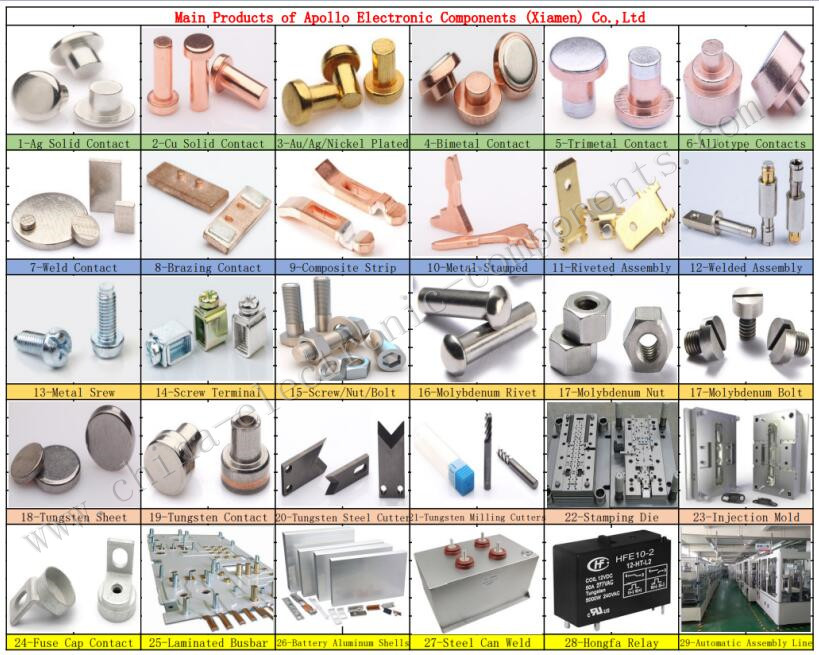

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !