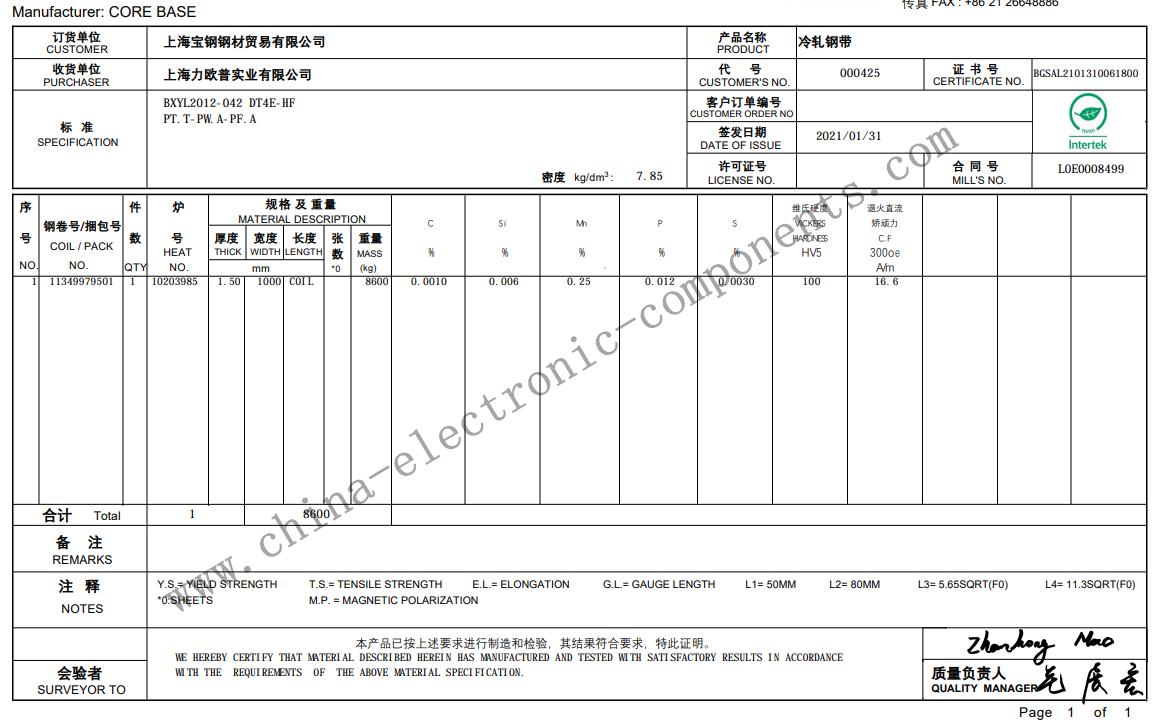

1-Base Material: Electrician pure iron cold rolled steel (China model No DT4E/DT4C)

2-Surface Plating:

(1)Annealing with high temperature to remove coercive force;

(2)No plated or as require Copper-plated,Copper primer and nickel plating,etc.

3-OEM/ODM:Accepted,need your drawing

4-Free Samples:10-50pcs is allowed

5-Lead Time:Samples 10-20days,Orders 7-10days(including the tooling/die production)

6-Production Capacity:50,000,000 pcs/month

7-Packing:Inner plastic bag/box,Outer carton/pallet

8-Payment Item:T/T,L/C by USD/EUR/RMB

9-Quality Standard:ISO9000,IATF16949,RoHS,REACH

10-Application:Relay,Contactor,Switch,Thermostat,Breaker,other High/Low-voltage electrical appliances.

What is the function of the iron core in the middle of the coil?

The function of the coil and the iron core is to increase the intensity of the magnetic field. The Coil Core concentrates the magnetic lines of force around the coil and circulates through the Electromagnet Core. Remove the iron core, the magnetic induction between the coils will become smaller. The magnetic circuit, like the circuit, always find a place where the magnetic resistance (resistance) is small. The magnetic resistance of the Electrician Pure Iron Core is much smaller than that of air, so the magnetic flux goes from the iron core.

When the Coil Soft Iron Core is inserted into the energized solenoid, the iron core is magnetized by the magnetic field of the energized solenoid. The magnetized Straight Coil Core also becomes a magnet, so that the two magnetic fields are superimposed on each other, so that the magnetism of the solenoid is greatly enhanced. In order to make the electromagnet more magnetic, the Cold Heading Pure Iron Core is usually made into a hoof shape.

But note that the winding direction of the coil on the hoof-shaped Stator Core is opposite, clockwise on one side, and counterclockwise on the other side. If the winding directions are the same, the magnetization of the two coils on the Relay iron core will cancel each other out, so that the Coil Core does not show magnetism. The Electrician Pure Iron Core of the electromagnet is made of soft iron instead of steel. Otherwise, once the steel is magnetized, it will remain magnetic for a long time and cannot be demagnetized, and the strength of its magnetism cannot be controlled by the magnitude of the current, and the advantages of electromagnets will be lost.

The characteristics of electrical pure iron:

1-Good electromagnetic performance: low coercivity, high permeability, high saturation magnetic induction, stable magnetism and non-magnetic aging.

2-The smelting process of electromagnetic pure iron series adopts hot metal pretreatment, RH refining, electromagnetic stirring and other processes. The interior is dense and uniform, with low gas content and low carbon content in the finished product.

3-Good cold and hot processing performance:Electrician Pure Iron cold processing can meet the process requirements of turning, piers, punching, bending, drawing, etc., hot processing, such as re-forging and re-rolling, the sensitivity of red brittleness is small, and it can be guaranteed in a larger temperature range Processing within.

4-Good surface quality: good welding and electroplating performance.

5-High dimensional accuracy: ultra-precision cold-rolled plates can be provided, such as thick plates ≤1.5mm, and the thickness tolerance can be guaranteed ≤±0.01mm.

Reduce the coercive force or stress of electrical pure iron through high temperature annealing

Why is the coercivity value of pure iron Cold rolled steel material increased a lot after processing the finished product. The product use effect is not ideal. Is there something wrong with the material, or is there something hidden? For this reason, our company specially organizes the following information, hoping to solve problems for our friends.

①Why should pure iron be annealed?

Answer: Because cold working causes many crystal defects (dislocations, stacking faults, etc.) in pure iron, and causes internal stress, increases the difficulty of magnetic domain wall movement, increases Hc, and decreases μm value. In order to eliminate these adverse effects, electrical pure iron must be subjected to stress relief annealing or recrystallization annealing.

②What are the improvements to pure iron Cold rolled steel after annealing?

Answer: The high annealing temperature makes the crystal grains coarser and eliminates the stress of the pure iron material, which is beneficial to the magnetic permeability. Therefore, the stress-relief annealing generally adopts the highest temperature that does not cause α←→γ phase transition to avoid phase transition during cooling. Grain refinement.

③The annealing temperature and time of Electrician Pure Iron?

Answer: Yaoqiang pure iron usually adopts the recrystallization annealing process system to eliminate the cold working stress: install the furnace below 600℃, raise the temperature to 800℃ with the furnace, and then slowly heat to 830~890℃, keep the temperature for 4h, and then the temperature is no more than The cooling rate of 50℃/h is cooled to 700℃, and finally cooled to below 500℃ with the furnace. The entire annealing is performed in hydrogen or vacuum.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !