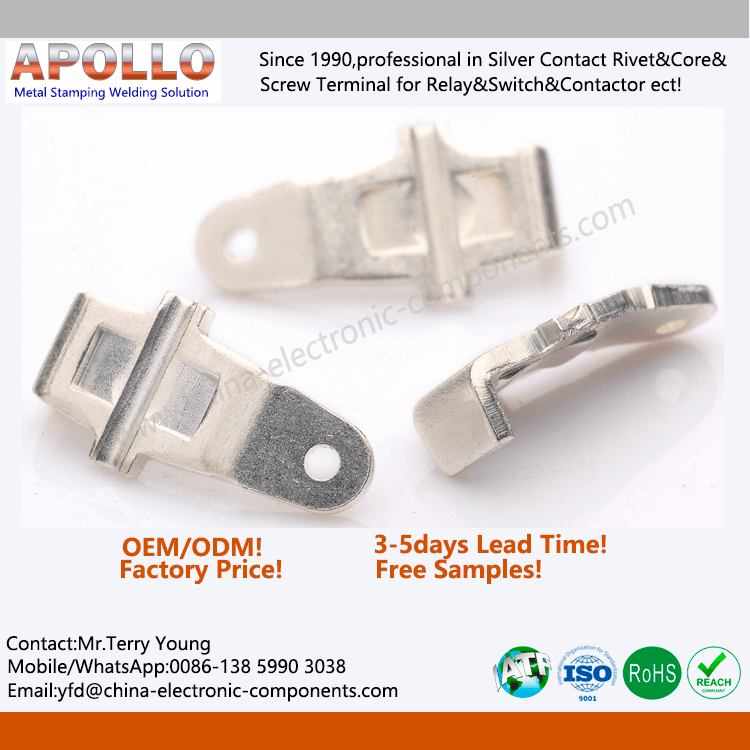

2-Surface Plating:No plated or as require Silver-plated,Gold-plated,Nickel-plated.

3-OEM/ODM:Accepted,need your drawing

4-Free Samples:10-50pcs is allowed

5-Lead Time:Samples 25-30days,Orders 7-10days(including the tooling/die production)

6-Production Capacity:50,000,000 pcs/month

7-Packing:Inner plastic bag/box,Outer carton/pallet

8-Payment Item:T/T,L/C by USD/EUR/RMB

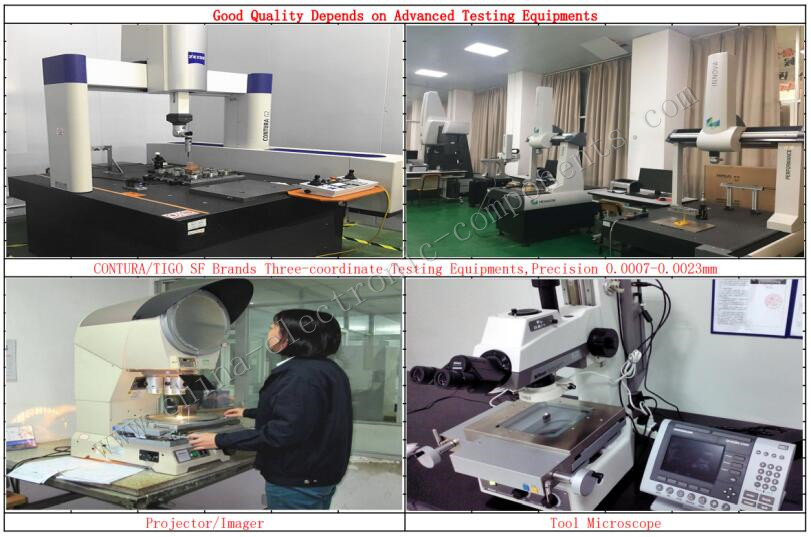

9-Quality Standard:ISO9000,IATF16949,RoHS,REACH

10-Application:Relay,Contactor,Switch,Thermostat,Breaker,other High/Low-voltage electrical appliances.

The role of ultrasonic cleaning before Copper Stamping Parts electroplating

The pre-treatment process of product electroplating is very important. The general traditional process uses acid to treat the Red Copper Stamping Parts, which causes serious environmental pollution and poor working environment. At the same time, the biggest drawback is that the residual acid after pickling and rust removal of complex parts is difficult. Rinse it off. After the Copper Pressed Components are electroplated, the time is not long, and corrosion appears along the cracks, which damages the surface of the electroplating layer, and seriously affects the appearance and internal quality of the Copper Pressed Stamped Parts. After the ultrasonic cleaning technology is applied to the pre-treatment of electroplating, not only can the dirt on the surface of the object and the gap be quickly peeled off, but the sprayed layer of the electroplated Copper Stamped is firm and will not return rust.

Using the cavitation effect produced by ultrasonic waves in the liquid, the oil stains on the surface of the Custom Metal Copper Stamped can be cleaned, and with appropriate cleaning agents, the surface of the workpiece can be quickly treated with high cleanliness.The electroplating process has high requirements on the surface cleanliness of the Customized Electrical Stamping Copper Spring, and the ultrasonic cleaning technology is an ideal technology that can meet this requirement. Using ultrasonic cleaning technology, it can replace solvents to clean oil; it can replace electrolytic oil; it can replace strong acid etching to remove rust and scale on the surface of carbon steel and low-alloy steel.

After electroplating of Copper Spring Electrical Parts, various treatments are performed on the coating to enhance various properties of the coating, such as corrosion resistance, discoloration resistance, solderability, etc.

1-Dehydration treatment: Add a dehydrating agent to the water, such as post-treatment after bright nickel plating.

2-Passivation treatment: improve the corrosion resistance of the coating, such as galvanizing.

3-Anti-tarnishing treatment: Add anti-tarnishing agents in water, such as silver plating, tin plating, imitation gold plating, etc.

4-Improve solderability treatment: such as tin plating, so the pros and cons of the post-treatment process directly affects the quality of these functions of the coating.

Metal Custom Copper Stamping process characteristics:

(1) Copper Stamping is a processing method with high production efficiency and low material consumption. The stamping process is suitable for the production of larger batches of parts, which is easy to realize mechanization and automation, and has high production efficiency. At the same time,Copper Sheet Stamping production can not only strive to achieve less waste and no waste production, but also has margins in some cases. The leftover material can also be fully utilized.

(2) The operation process is convenient and does not require the operator to have a higher level of skill.

(3) The Electrical Copper Stamping Parts generally do not need to be mechanically processed, and have high dimensional accuracy.

(4) Metal Stamping Parts Electric Copper have better interchangeability. Stability of stamping processing is better, the same batch of stamping parts. Can be used interchangeably without affecting assembly and product performance.

(5) Since the Copper Stamping Parts are made of plates, its surface quality is better, which provides convenient conditions for subsequent surface treatment processes (such as electroplating and painting).

(6) Copper Strip Stamping can obtain parts with high strength, high rigidity and light weight.

(7) The cost of Red Copper Stamping Parts produced in batches with molds is low.

(8) Precision Copper Stamping Parts can produce parts with complex shapes that are difficult to process with other metal processing methods.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !