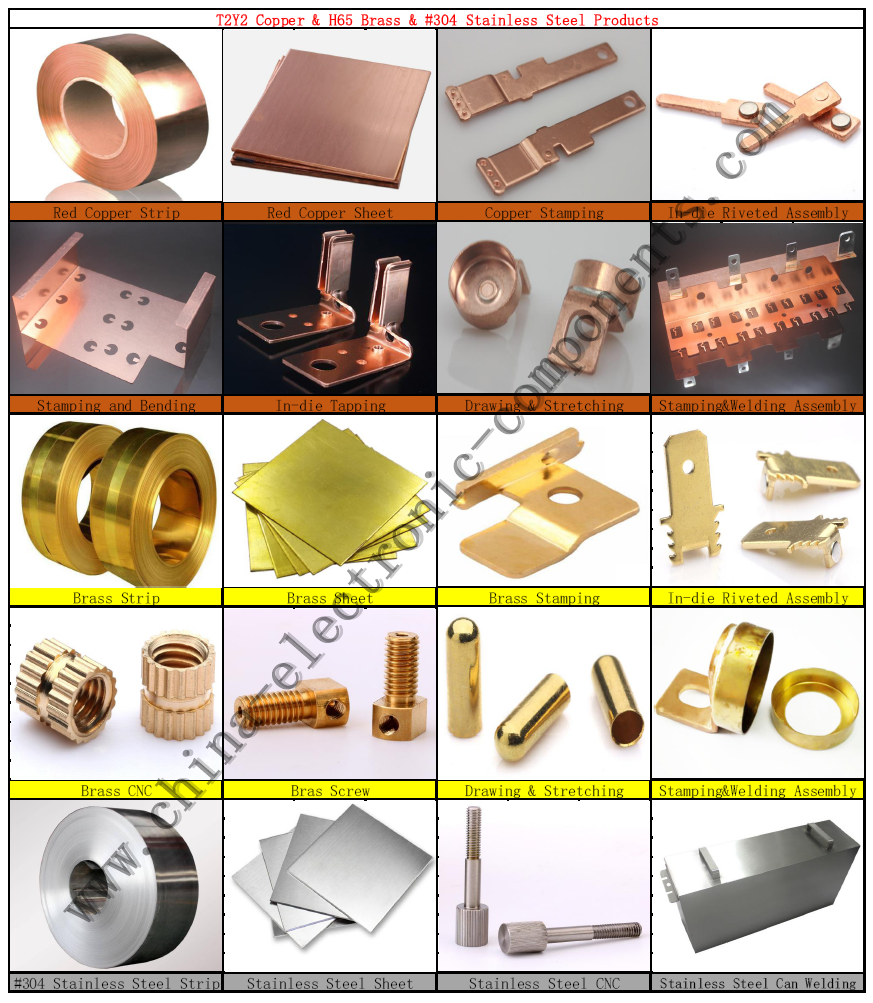

1-Base Material: Red Copper T2Y2

2-Surface Plating:No plated or as require Silver-plated,Gold-plated,Nickel-plated.

3-OEM/ODM:Accepted,need your drawing

4-Free Samples:10-50pcs is allowed

5-Lead Time:Samples 25-30days,Orders 7-10days(including the tooling/die production)

6-Production Capacity:50,000,000 pcs/month

7-Packing:Inner plastic bag/box,Outer carton/pallet

8-Payment Item:T/T,L/C by USD/EUR/RMB

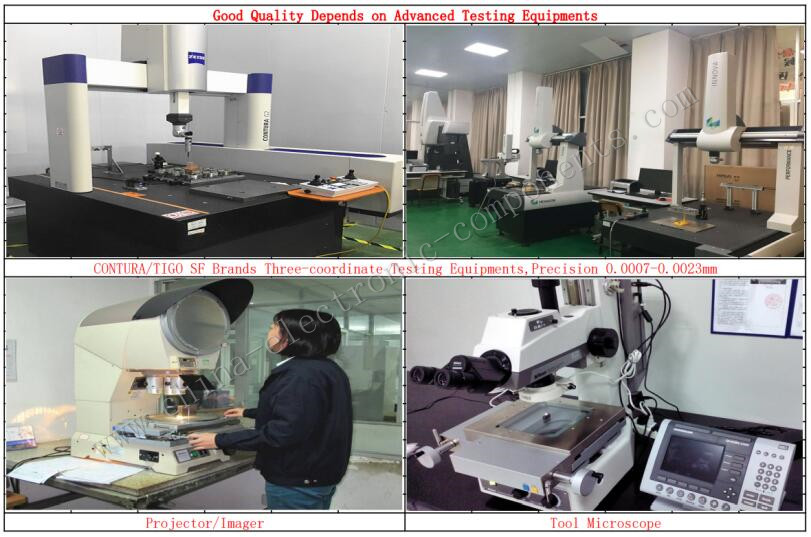

9-Quality Standard:ISO9000,IATF16949,RoHS,REACH

10-Application:Relay,Contactor,Switch,Thermostat,Breaker,other High/Low-voltage electrical appliances.

Metal Custom Copper Stamping process sequence:

1-Punching: The stamping process (including punching, blanking, trimming, cutting, etc.) that separates the sheet.

2-Bending: The stamping process of bending the Red Copper Sheet into a certain angle and shape along the bending line.

3-Deep drawing: Copper Stamping Parts process that transforms a flat sheet into various open hollow parts, or further changes the shape and size of the hollow parts.

4-Fine blanking: For products with high blanking precision, products with high requirements on size and surface light can be achieved through fine blanking molds to meet the requirements of the drawings.

5-Local forming: the Copper Stamping process (including flanging, bulging, leveling and shaping processes, etc.) that uses various local deformations of different properties to change the shape of the blank or stamping part.

How to deal with the oxidized red copper parts to restore their brightness?

Red copper is a relatively pure copper material, which is close to pure copper. Because of its excellent processing performance, good electrical conductivity, good plasticity, Copper Stamping also has excellent thermal conductivity, ductility and corrosion resistance. Therefore, Stamping Copper Sheet is often used to make electrical equipment such as generators, busbars, cables, switchgear, transformers, heat exchangers, pipelines, flat plate collectors for solar heating devices, hot pots and other heat-conducting equipment, etc. During the use of these Custom Copper Stamping, it is often easy to oxidize, change color, blacken and rust on the surface of the Copper Sheet Stamping, which will affect the appearance and performance of the product. Then how should the copper rust be dealt with? Questions, to avoid problems during use? Here are some ways to deal with it.

1-If the surface requirements of the Precision Copper Stamping Parts are not high, and the size requirements are not high (such as the surface of the Red Copper Parts in the above picture is severely oxidized), physical polishing can be used to solve the problem of surface oxides, such as physical polishing with a polishing wheel. Use sandpaper to remove oxides on the surface of Red Copper Stamping Parts. The disadvantage of this method is that the operation is complicated, the size of the Copper Pressed Components are changed greatly, and the copper parts with complex surface structure cannot be processed;

2-If there are requirements for the surface condition of the Copper Pressed Stamped Parts, such as the requirement that the size cannot be changed too much, the only choice is to use chemical methods to remove the oxides on the surface of the Copper Stamped parts. Chemical methods can use copper bright cleaning to clean and remove the oxides on the surface of the Custom Metal Copper Stamped to achieve the purpose of restoring the surface finish of the copper parts;

3-If the brightness of the surface of the Customized Electrical Stamping Copper Spring is very high, and the size is strict, even if the Stamping Parts Copper Spring has a complex structure, it needs to be processed by a chemical polishing process. Using copper environmental protection chemical polishing, the surface of the Copper Spring Electrical Parts can achieve a mirror gloss effect.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !