1-Products Name: Metal Screw & Terminal Block & Hardware Fasteners

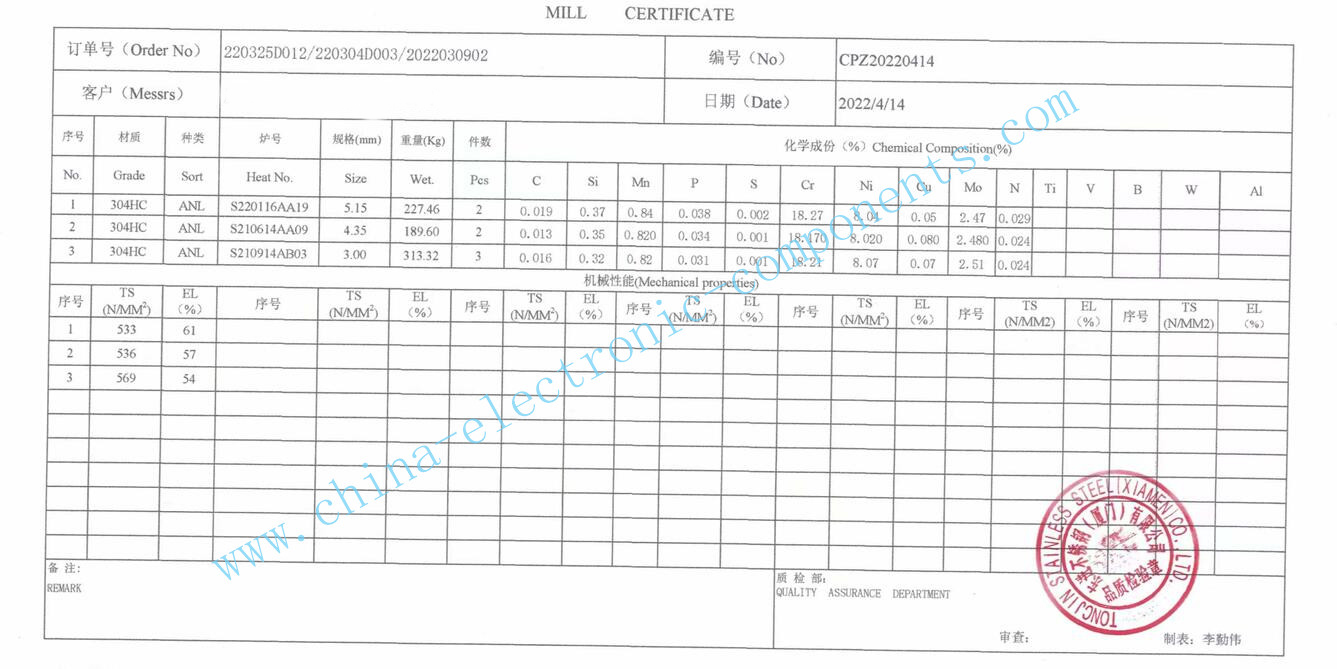

2-Raw Material:

(1)Screw Rivet: Carbon Steel (hot rolled steel wire ML08AL and cold rolled steel plate SPCC), Stainless Steel (304HC),Aluminum Alloy,Copper,Brass,etc,OEM accepted;

(2)Terminal Block: Carbon Steel, Copper,Brass,OEM accepted;

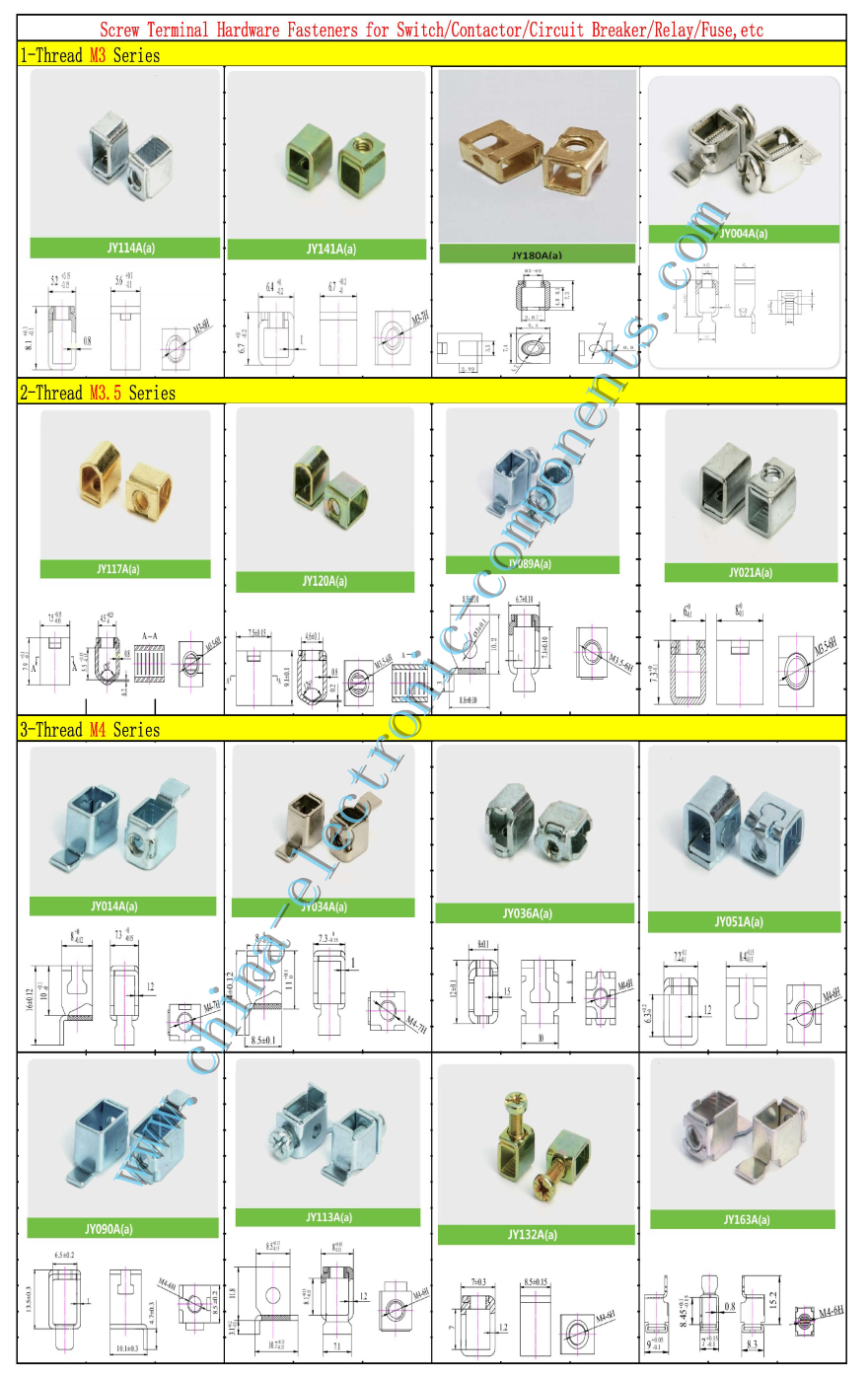

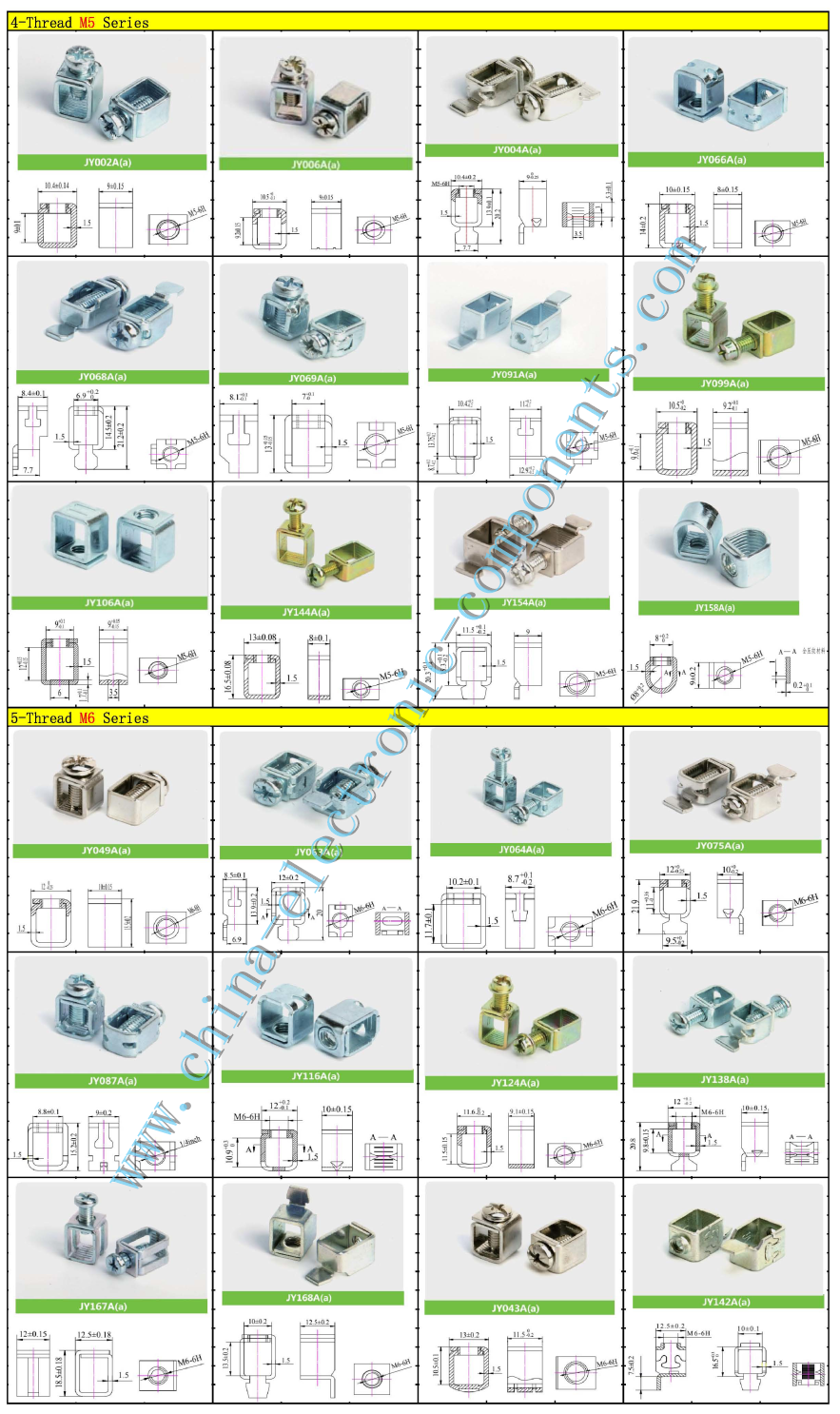

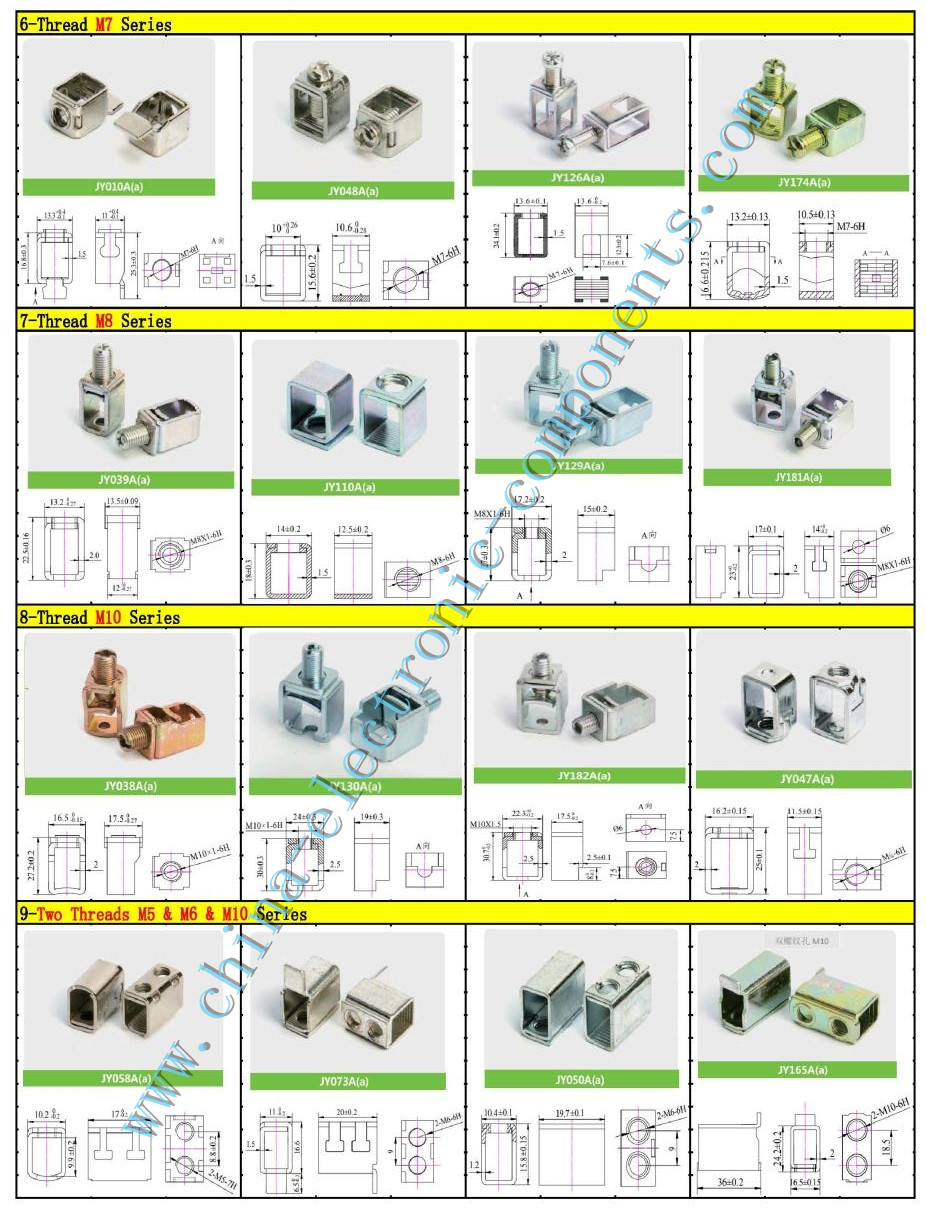

3-Screw Terminal Size:

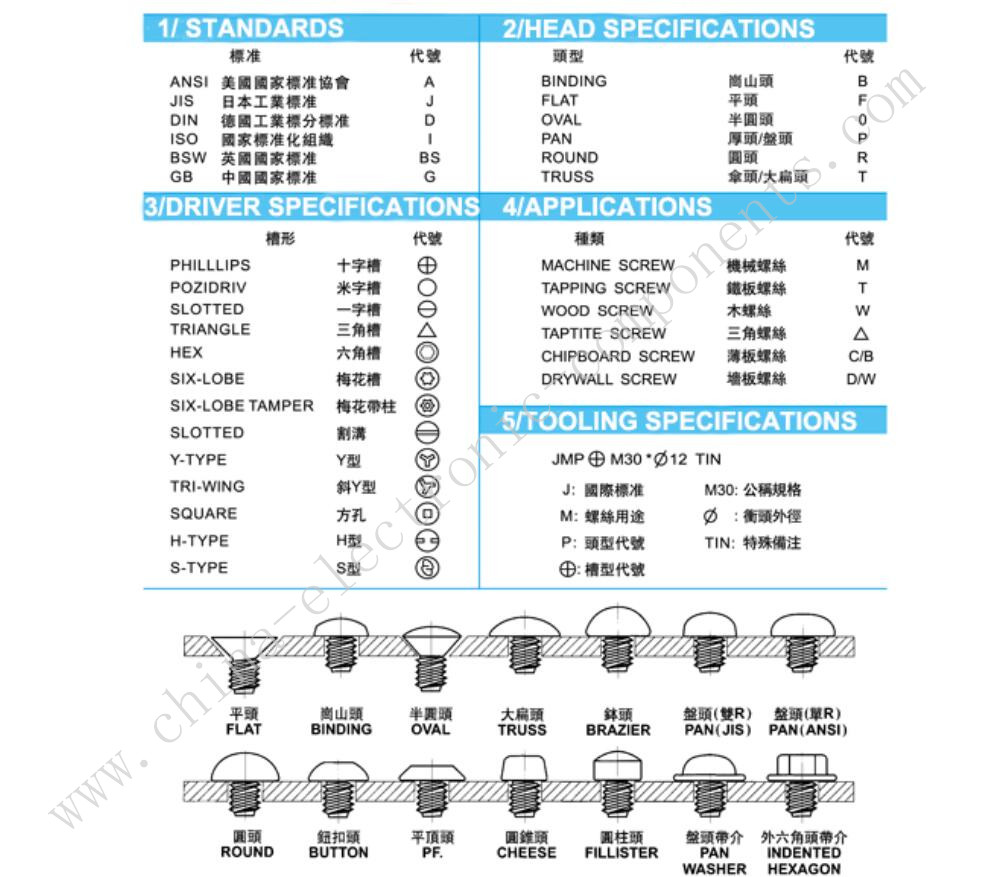

(1)M3/M3.5/M4/M5/M6/M7/M8/M10/M12/M14/M16/M18/M20,etc,OEM accepted

(2)British standard (BSW), German standard (DIN), German standard (DIN), Chemical industry (HG), Machinery (JB) and other standard or non-standard fasteners.

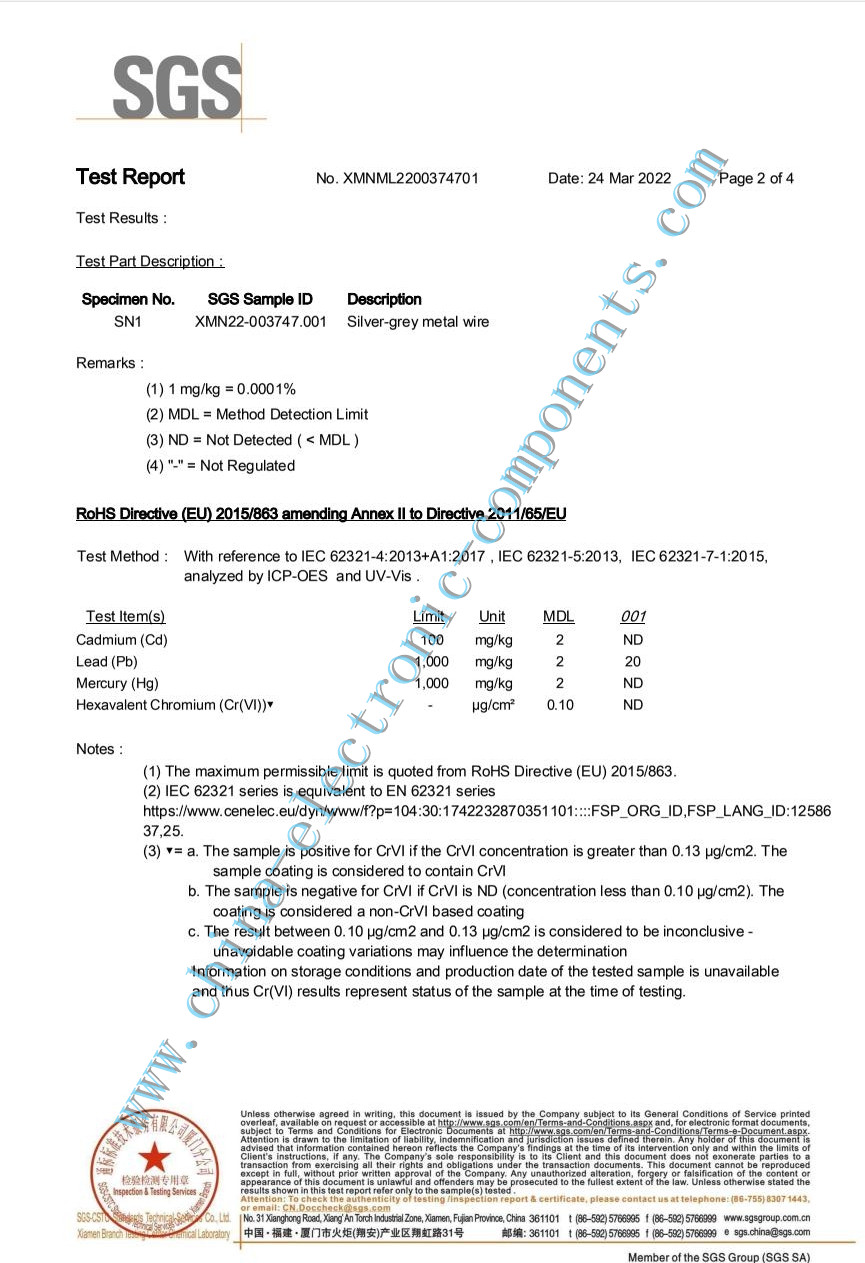

4-Surface Treatment:

(1)Electroplating Environmentally Friendly Zinc (galvanized): White Zinc, Color Zinc, Blue Zinc, Black Zinc;

(2)Other Plating: Nickel,Chrome,Lat,Pot Black,Dacromet,Copper,Tin,Silver, etc.

5-Plating Thickness:

(1)Normal economic plating thickness 4-12μm

(2)Hot-dip galvanizing thickness 37-54μm

(3)According to customer requirements,OEM accepted;

6-Salt Spray Test(NSS standard,sodium chloride concentration 5% & PH6.5-7.2):

Usually 48-96 hours, according to customer requirements, salt spray test is related to plating thickness

7-Free Samples:10-50pcs is allowed

8-Lead Time:7-15days(including the tooling/die and samples)

9-Production Capacity:50,000,000 pcs/month

10-Products Packing:Inner plastic bag/box,Outer carton/pallet

11-Payment Item:T/T,L/C by USD/EUR/RMB

12-Quality Standard:ISO9000,IATF16949,RoHS,REACH

13-Terminal Application:Relay,Contactor,Switch,Thermostat,Circuit Breaker,Energy Meter,GAS Meters,other High/Low-voltage electrical appliances.

We are professional in the production and sales the Screw Block Terminal for Circuit Breakers, Contactors, Building Electrical Appliances, Electricity Meters, Fuses and other medium and low voltage electrical hardware fasteners. In 2009, our company successfully developed the blanking forming synchronous manufacturing process of the Screw Terminal, changed the structure of the Screw Terminal Block from the mosaic type to the riveted type, and applied for a patent. This improvement of Screw Terminal Wire Connectors not only doubles the production efficiency, but also greatly increases the mechanical strength of the Screw Type Terminal Blocks, providing 0.5-1.0N.m of torque compared to the traditionally constructed Screw Clamp Terminal.

Screw Clamp Terminal Blocks are generated to facilitate the application of wire. Rail Terminal Block is actually a piece of metal sealed in insulating plastic. There are holes at both ends to insert wires. There are screws for fastening or loosening. Screw Clamp Connecting Terminal Block is suitable for interconnecting a large number of wires. There are special Customize Clamp Wire Terminal in the power industry. The terminal box is full of Screw Clamp Terminal Block, single-layer, double-layer, current, voltage, common, breakable, etc.

In fact, there are many classifications of Screw Type Terminal: European-style Electrical Terminal Screws, plug-in Terminal Screw Connector, barrier-type Screw in Terminal Block, spring-type Clamp Terminal Block, track-type Screw Connector Block, through-wall Screw Block Terminal, photoelectric coupling Type Electrical Screw Terminal series, etc.

What should be paid attention to in the special treatment of Screw Clamp Terminal Block and Hardware Fasteners surface electroplating process?

The special surface treatment of the Screw Terminal Block, Hardware Fasteners (Screws, Nuts, Bolts, Washers) are better exert its performance. In order to improve the hardness of the screw, Apollo hardware screws generally choose the electroplating process to treat the surface of the screw terminal.

When the Screws, Nuts, Bolts, Washers fasterners and Electrical Crimping Frame are electroplated, for the safety and effectiveness of the whole process, some matters need to be paid attention to in the operation process of the Column Joint Fasteners. Here's a detailed introduction to the screw surface treatment electroplating process. The precautions are as follows:

1- Clean the Electric Iron Terminal. First, check whether there are burrs, cracks, etc on the surface of the Screws Terminal Block, and polish it;

2-Contaminants on the surface of the Terminal Crimping Frame, such as metal chips, oil or oxide skin, etc., the Frame Screw Crimp Terminals must be thoroughly cleaned before electroplating, so that the effect of electroplating will be better;

3- Grind and eliminate defects such as perforated oxide skin of Terminal Screw Combination welding parts;

4- The minimum tensile strength of the steel of the Screw Fastener Terminals shall not be lower than 1000MPA, and the ground, machined and cold-formed products should be heat treated before cleaning and electroplating to release the stress, the minimum temperature is 190 degrees, and the time is not less than 3 hours.

Contact Information:

Mr.Terry Young (Sales Manager&Technology Engineer)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor&Breaker ect Riveting&Welding solutions !