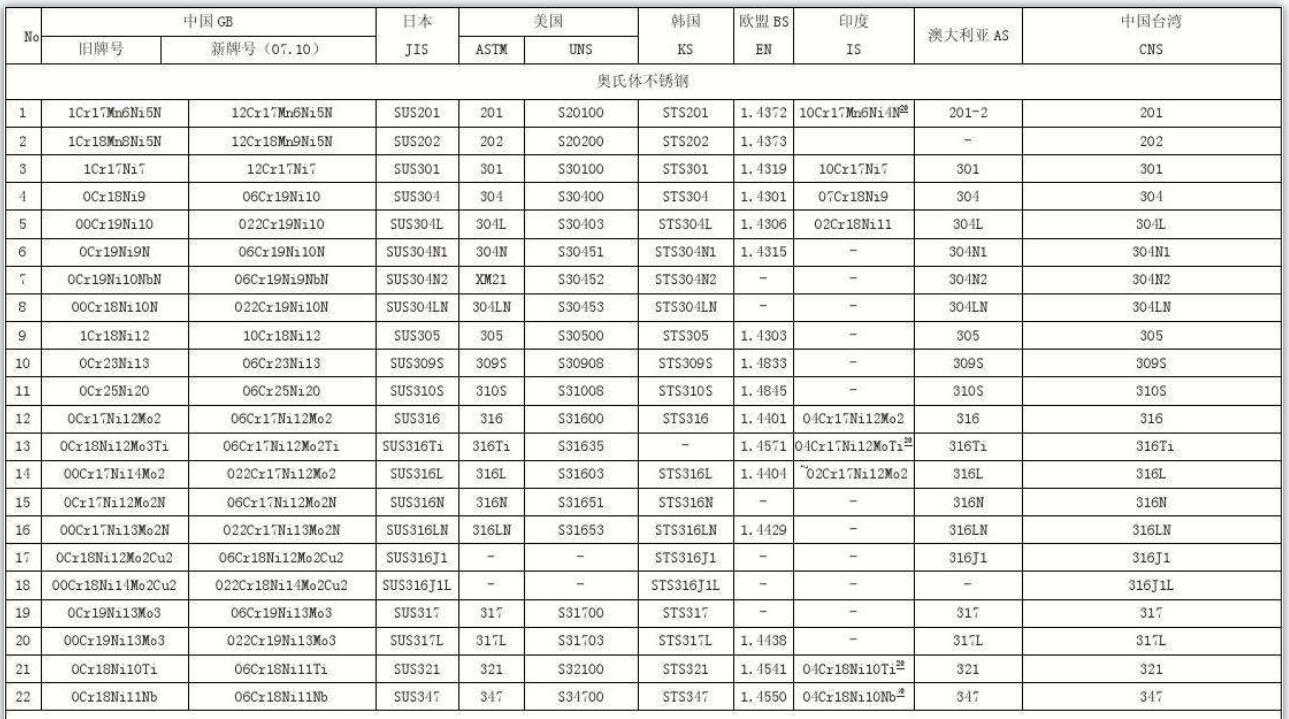

1-Base Material: Stainless Steel Stamping (Model No 304,316,201,347,321)

2-Surface Plating:

(1)Annealing with high temperature to remove coercive force;

(2)No plated or as require Electroplating/Mirror/Sandblasting/Coloring/Drawing/Spraying treatments,etc.

3-OEM/ODM:Accepted,need your drawing

4-Free Samples:10-50pcs is allowed

5-Lead Time:Samples 10-20days,Orders 7-10days(including the tooling/die production)

6-Production Capacity:50,000,000 pcs/month

7-Packing:Inner plastic bag/box,Outer carton/pallet

8-Payment Item:T/T,L/C by USD/EUR/RMB

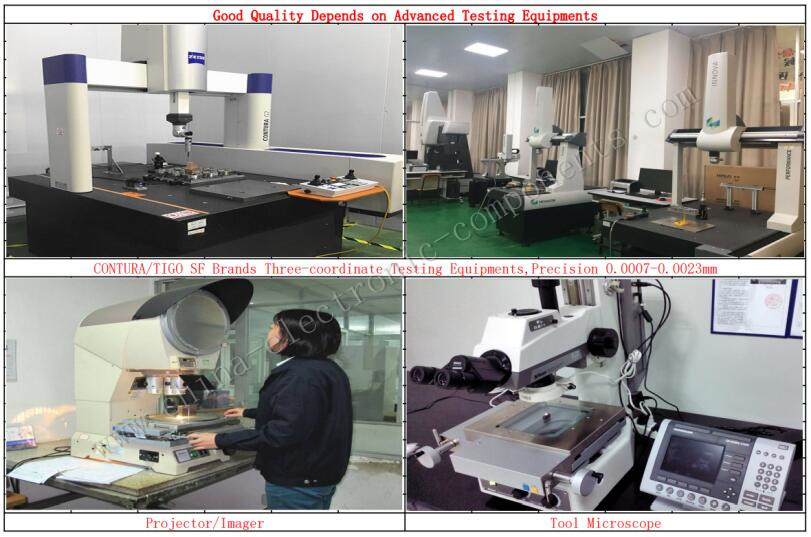

9-Quality Standard:ISO9000,IATF16949,RoHS,REACH

10-Application:Auto parts, machinery, electronics, home appliances, electrical instruments, switches, toys, sports equipment and other industries.

What are the main characteristics of stainless steel?

Stainless Steel is defined in GB/T20878-2007 as a steel with stainless steel and corrosion resistance as its main characteristics, with a chromium content of at least 10.5% and a carbon content of no more than 1.2%.Stainless steel is the abbreviation of stainless and acid-resistant steel. The steel that is resistant to weak corrosive media such as air, steam and water or has stainless steel is called stainless steel; Corroded steel is called acid-resistant steel.

1-Stainless Steel Stamping Weldability: Different uses have different requirements for weldability. Most products have requirements for welding performance, such as thermos cups, steel pipes, water dispensers, etc.

2-Stainless Steel Stamped Corrosion resistance: Corrosion resistance is a significant property of stainless steel. Different types of stainless steel have different corrosion resistance, including corrosion resistance strength and corrosion resistance category. Some foreign buyers will also test the corrosion resistance when purchasing stainless steel, weigh the solution after importing it, and measure the corrosion resistance by weight loss.

3-#304 Stainless Steel Polishability: All stainless steel products need to be polished, and only a few uses such as water dispenser liner and water heater do not need polishing, so stainless steel raw materials generally have good polishing properties.

4-Custom Stainless Steel Heat resistance: Stainless steel has excellent heat resistance, and some models are known for high temperature resistance. The heat resistance of stainless steel means that stainless steel can still maintain good physical and mechanical properties at high temperature. Among them, the high temperature resistance of 310S stainless steel is remarkable, and the maximum service temperature can reach 1200 °C.

Features of Stainless Steel Stamping Parts

1-High yield point, high hardness, significant cold work hardening effect, prone to cracks and other defects.

2-The thermal conductivity is worse than that of ordinary carbon steel, resulting in large deformation force, large punching force and deep drawing force.

3-During deep drawing, the plastic deformation is severely hardened, and the thin plate is easy to wrinkle or fall off the bottom during deep drawing.

4-The deep drawing die is prone to adhesion lumps, resulting in serious scratches on the outer diameter of the parts.

5-When deep drawing, it is difficult to achieve the expected shape.

The above is determined by the performance of stainless steel itself, which is mainly affected by the following five factors: one is the performance of raw materials; the other is the structure of the mold and the stamping speed; the third is the material of the mold; the fourth is the stamping lubricant; the fifth is the process route s arrangement.

(1) The quality of the raw material Stamping 304 Stainless Steel is also an important factor affecting the stamping performance, and regular raw materials that meet the national standard must be purchased. For hard materials, annealing must be carried out before stamping to improve processing performance.

(2) The structure and Stainless Steel Stamping speed of the die In order to improve the difficulty of deep drawing, the blank holder surface of the blank holder 2 can be made oblique, and under the action of the blank holder ring, it is completely in contact with the blank holder surface and the die, which can make the blank holder 2 be inclined. The material at the fillet of the die is subjected to a large blank holder force, thereby improving the difficulty of deep drawing.

Contact Information:

Mr.Terry Young (Sales Manager&Technology Engineer)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor&Breaker ect Riveting&Welding solutions !