1-Base Material: H59/H62/H65 Brass Stamping Parts

2-Surface Plating:No plated or as require Silver-plated,Nickel-plated,etc

3-OEM/ODM:Accepted,need your drawing

4-Free Samples:10-50pcs is allowed

5-Lead Time:Samples 20-30days,Orders 7-10days(including the tooling/die production)

6-Production Capacity:50,000,000 pcs/month

7-Packing:Inner plastic bag/box,Outer carton/pallet

8-Payment Item:T/T,L/C by USD/EUR/RMB

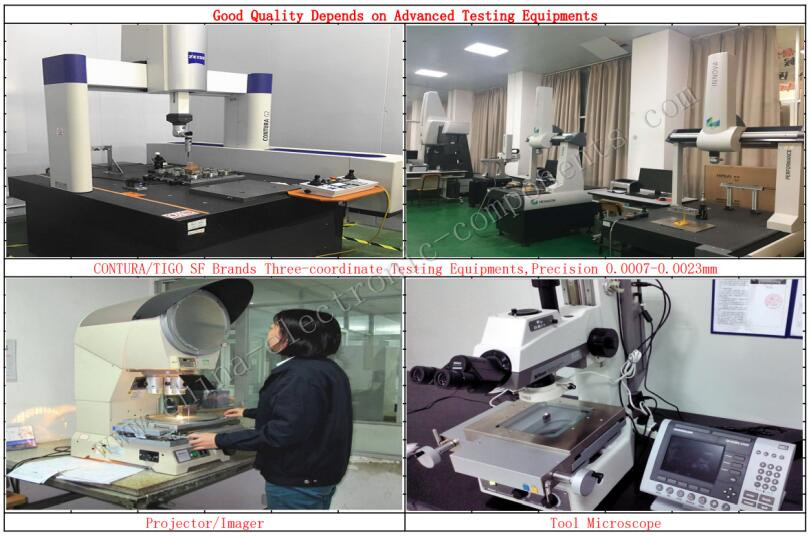

9-Quality Standard:ISO9000,IATF16949,RoHS,REACH

10-Application:Relay,Contactor,Switch,Thermostat,Breaker,other High/Low-voltage electrical appliances.

Brass Stamping Terminal has very good plasticity (the best among brass) and high strength, good machinability, easy welding, and very stable to general corrosion, but Brass Stamping Part is prone to corrosion cracking; Brass Strip Stamped is copper and Zinc alloy is named after its yellow color.If it is a variety of alloys composed of two or more elements, it is called special brass. Such as copper alloys composed of lead, tin, manganese, nickel, iron, and silicon. Custom Brass Stamping has strong wear resistance. Special brass is also called special brass. It has high strength, high hardness and strong chemical resistance. The mechanical properties of cutting are also outstanding. The seamless copper tube drawn from brass is soft and has strong wear resistance. Brass seamless pipes can be used for heat exchangers and condensers, cryogenic pipelines, and subsea transportation pipes. Manufacture of sheets, bars, bars, pipes, casting parts, etc. The Stamped Brass Terminal content is 62%~68%, the plasticity is strong, and the pressure equipment is manufactured.

Metal Custom Brass Stamping process sequence:

1-Punching: The stamping process (including punching, blanking, trimming, cutting, etc.) that separates the sheet.

2-Bending: The stamping process of bending the Red Copper Sheet into a certain angle and shape along the bending line.

3-Deep drawing: Brass Stamping Parts process that transforms a flat sheet into various open hollow parts, or further changes the shape and size of the hollow parts.

4-Fine blanking: For products with high blanking precision, products with high requirements on size and surface light can be achieved through fine blanking molds to meet the requirements of the drawings.

5-Local forming: the Brass Stamping process (including flanging, bulging, leveling and shaping processes, etc.) that uses various local deformations of different properties to change the shape of the blank or Brass stamping part.

How to wash and brighten the surface oxidation of Brass parts after processing?

The simple treatment method of brass material after oxidation and rust-the main process flow of chemical method is: firstly carry out the cleaning treatment of oil removal and oxide removal → water washing → Custom Brass Stamping polishing treatment→ Brass Stamping protection treatment. The Brass Stamping Parts processed by this method can not only restore the original luster (or even brighter) of the copper parts, but also prevent the Stamped Brass Terminal from being oxidized and keep the brass parts bright as new for a long time.

One is that the oxidized part of the Brass Stamping Processing surface can be cleaned by surface pickling, but the pickling time is relatively short. After pickling, if the surface is directly touched with hands or touched with water, it will quickly oxidize back.

Another method is to do the surface passivation treatment of the Brass Stamping. The anti-oxidation treatment of the surface lasts longer than the pickling process, and the color of the Stamping Brass Strip surface after passivation will look better, like rose gold.

Contact Information:

Mr.Terry Young (Sales Manager&Technology Engineer)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor&Breaker ect Riveting&Welding solutions !