1-Base Material:Beryllium Copper Relay Moving Spring Terminal

2-OEM/ODM:Accepted,need your drawing

3-Free Samples:10-50pcs is allowed

4-Lead Time:Samples 25-30days,Orders 7-10days(including the tooling/die production)

5-Production Capacity:50,000,000 pcs/month

6-Packing:Inner plastic bag/box,Outer carton/pallet

7-Payment Item:T/T,L/C by USD/EUR/RMB

8-Quality Standard:ISO9000,IATF16949,RoHS,REACH

9-Application:Relay,Contactor,Switch,Thermostat,Breaker,other High/Low-voltage electrical appliances.

Beryllium copper, also known as beryllium bronze, is the "king of elasticity" in copper alloys. After solution aging heat treatment, Beryllium Copper Stamping with high strength and high conductivity can be obtained. High-strength cast beryllium bronze alloy, after heat treatment, not only has high strength, high hardness, but also has the advantages of wear and corrosion resistance, excellent casting performance, Beryllium Copper Stamped is suitable for manufacturing various molds, explosion-proof safety tools, and wear-resistant Parts such as cams, gears, worm gears, bearings, etc.

High beryllium copper has the characteristics of high strength, high hardness, high conductivity, high elasticity, wear resistance, fatigue resistance, corrosion resistance and small elastic hysteresis. Beryllium Copper Stamping Spring is mainly used for temperature controllers, mobile phone batteries, computers, auto parts, micro Motors, brush needles, high-grade bearings, glasses, contacts, gears, punches, various non-spark switches, various welding electrodes and precision casting molds, etc.

Beryllium copper alloy stamped terminal has the characteristics of high strength, high hardness, high conductivity, high elasticity, wear resistance, fatigue resistance, corrosion resistance and small elastic hysteresis. Beryllium Copper Stamping Spring use: all kinds of welding electrodes and precision casting molds, temperature controllers, mobile phone batteries, computers, auto parts, micro motors, brush needles, high-grade bearings, glasses, contacts, gears, punches, all kinds of non-sparking Switch etc. Product designation: C17200 beryllium copper, C17500 beryllium cobalt copper, C17510 beryllium nickel copper. Product types: bars, cakes, bars, blocks, hexagonal bars, plates, strips, wires, tubes, etc. Hardness: >HRB 100 Conductivity: 45-60%IACS.

Phosphor bronze has higher corrosion resistance, abrasion resistance, and no sparks during impact. Used for medium-speed and heavy-duty bearings, with a maximum working temperature of 250°C. Customized Beryllium Copper Stamping has the characteristics of self-aligning, insensitive to deflection, uniform force on the bearing, high bearing capacity, radial load at the same time, and self-lubricating without maintenance. Tin-phosphorus bronze is a kind of copper alloy, which has good electrical conductivity, is not easy to generate heat, ensures safety and has strong fatigue resistance. The socket reed of tin-phosphorus bronze has a hard-wired electrical structure, no rivet connection or frictionless contact, which can ensure good contact, good elasticity, and smooth insertion. The alloy has excellent machining properties and chip-forming properties, which can quickly shorten the processing time of parts.

Metal Custom Copper Stamping process sequence:

1-Punching: The stamping process (including punching, blanking, trimming, cutting, etc.) that separates the sheet.

2-Bending: The stamping process of bending the Red Copper Sheet into a certain angle and shape along the bending line.

3-Deep drawing: Copper Stamping Parts process that transforms a flat sheet into various open hollow parts, or further changes the shape and size of the hollow parts.

4-Fine blanking: For products with high blanking precision, products with high requirements on size and surface light can be achieved through fine blanking molds to meet the requirements of the drawings.

5-Local forming: the Copper Stamping process (including flanging, bulging, leveling and shaping processes, etc.) that uses various local deformations of different properties to change the shape of the blank or stamping part.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

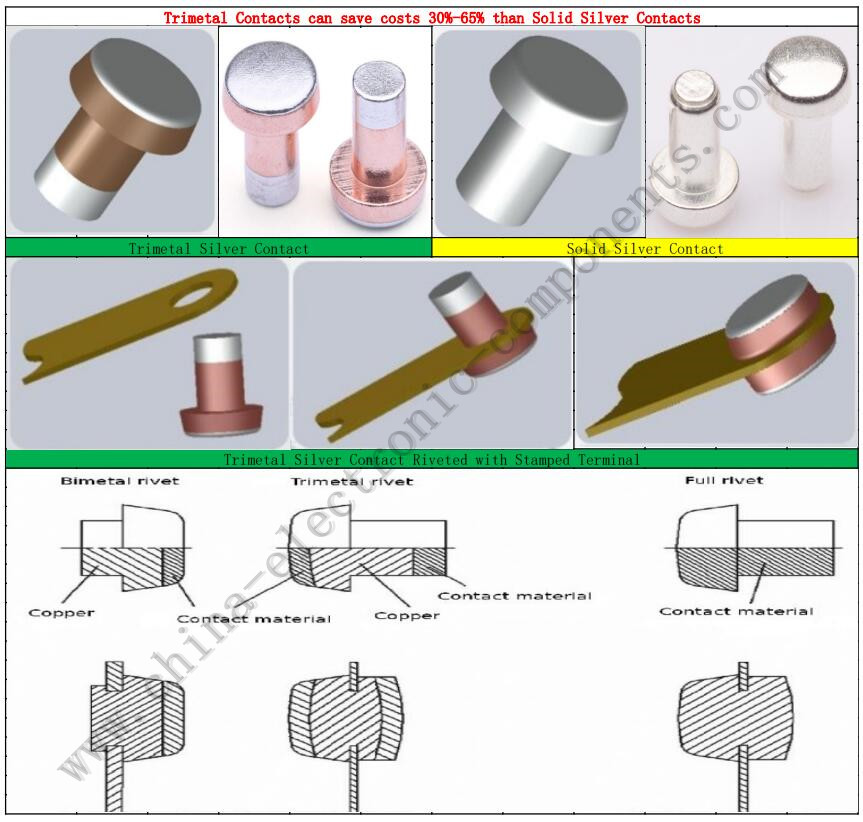

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !