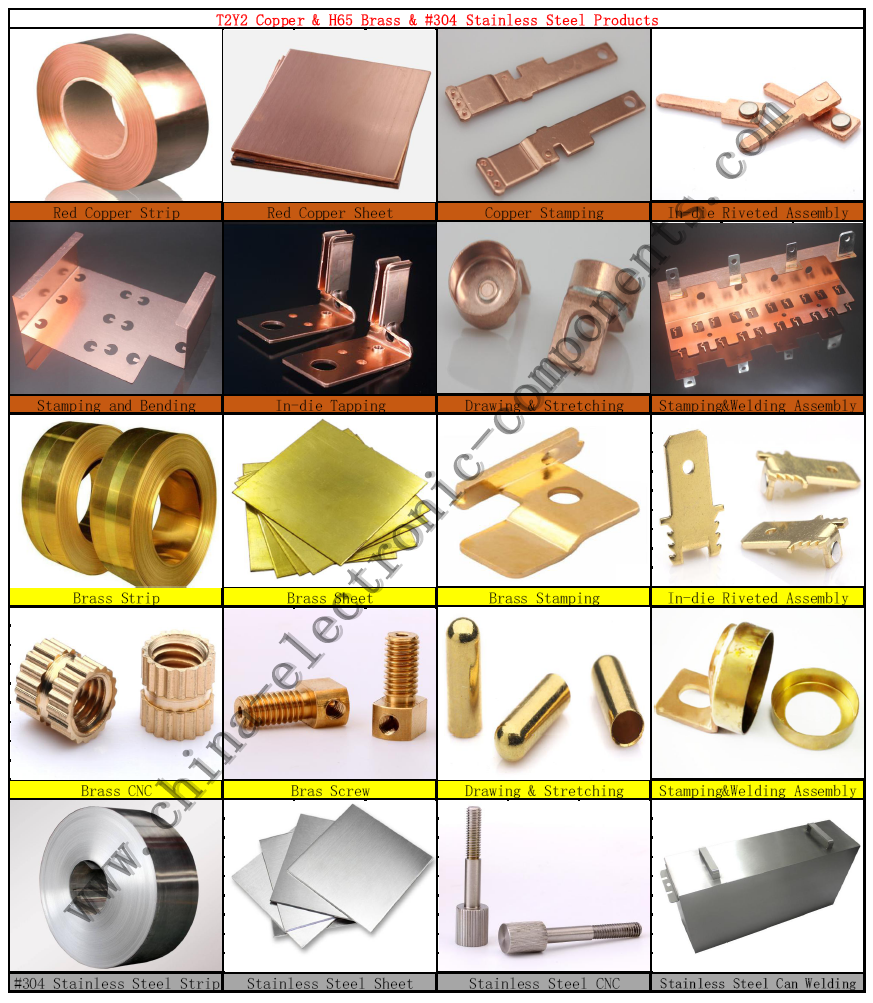

1-Products Name:Brass Strip Stamping and Electric Silver Contacts Rivted Assembly Set

2-Base Material: H59/H62/H65 Brass Stamping Part

3-Riveted Silver Contacts: Silver Solid Rivet,Copper Solid Rivet,Bimetal Silver Contact,Trimetal Contact Rivet,etc

4-Surface Plating:No plated or as require Silver-plated.

5-OEM/ODM:Accepted,need your drawing

6-Free Samples:10-50pcs is allowed

7-Lead Time:Samples 25-30days,Orders 7-10days(including the tooling/die production of Copper Stamped Part)

8-Production Capacity:50,000,000 pcs/month

9-Packing:Inner plastic bag/box,Outer carton/pallet

10-Payment Item:T/T,L/C by USD/EUR/RMB

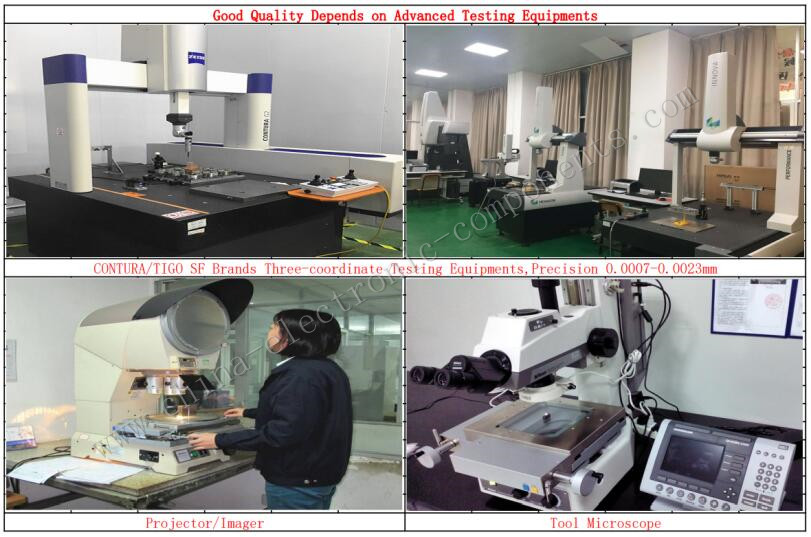

11-Quality Standard:ISO9000,IATF16949,RoHS,REACH

12-Application:Relay,Contactor,Switch,Thermostat,Breaker,other High/Low-voltage electrical appliances.

Our products Electric Silver Contact Features:

1-The contact resistance is low and stable

2-Good welding resistance and thorough opening and closing

3-Good conductivity

4-Good abrasion resistance,the contact surface not changed

5-Not easy to oxidize for a long time

6-Layer material is PAg,AgNi,AgSnO2,AgSnO2ln2O3,AgCdO,AgZnO etc,base material is Copper.

Brass Stamping Terminal has very good plasticity (the best among brass) and high strength, good machinability, easy welding, and very stable to general corrosion, but Brass Stamping Part is prone to corrosion cracking; Brass Strip Stamped is copper and Zinc alloy is named after its yellow color.If it is a variety of alloys composed of two or more elements, it is called special brass. Such as copper alloys composed of lead, tin, manganese, nickel, iron, and silicon. Custom Brass Stamping has strong wear resistance. Special brass is also called special brass. It has high strength, high hardness and strong chemical resistance. The mechanical properties of cutting are also outstanding. The seamless copper tube drawn from brass is soft and has strong wear resistance. Brass seamless pipes can be used for heat exchangers and condensers, cryogenic pipelines, and subsea transportation pipes. Manufacture of sheets, bars, bars, pipes, casting parts, etc. The Stamped Brass Terminal content is 62%~68%, the plasticity is strong, and the pressure equipment is manufactured.

Metal Custom Brass Stamping process sequence:

1-Punching: The stamping process (including punching, blanking, trimming, cutting, etc.) that separates the sheet.

2-Bending: The stamping process of bending the Red Copper Sheet into a certain angle and shape along the bending line.

3-Deep drawing: Brass Stamping Parts process that transforms a flat sheet into various open hollow parts, or further changes the shape and size of the hollow parts.

4-Fine blanking: For products with high blanking precision, products with high requirements on size and surface light can be achieved through fine blanking molds to meet the requirements of the drawings.

5-Local forming: the Brass Stamping process (including flanging, bulging, leveling and shaping processes, etc.) that uses various local deformations of different properties to change the shape of the blank or Brass stamping part.

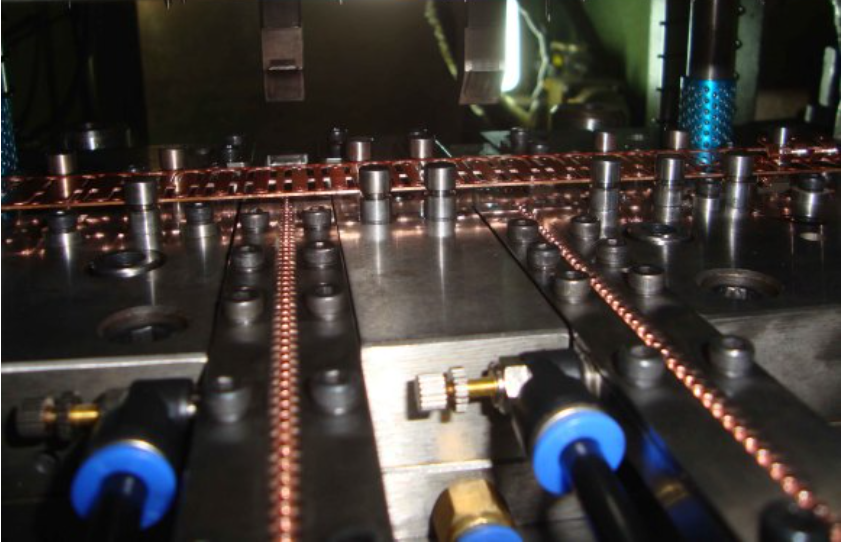

The process of In-die Riveting Silver Contacts

The process steps of the riveting of the silver contact riveting terminal in the mold: Contact Point progressive die punching brake reed → moving reed pickling → riveting Electrical Silver Contacts → bending of the Moving Spring Contact Assembly. Due to the large production volume of this product, in order to improve Production efficiency, stable product quality, and reduce production costs. The new process route formulated is: progressive die with material to produce moving reed strip → strip cleaning → strip riveting Electrical Silver Contacts and forming.

The technical requirements for the riveting of in-die silver contact riveting terminals: to achieve good in-mold riveting, the machining accuracy of mold parts is extremely high, oil cutting, PG, JG and other high-precision processing equipment are required; at the same time, the vibration plate and the mold are required. and the requirements for the gap and segment difference of the riveted Silver Contact Point and shrapnel are very high.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !