Our products Electric Silver Contact Features:

1-The contact resistance is low and stable

2-Good welding resistance and thorough opening and closing

3-Good conductivity

4-Good abrasion resistance,the contact surface not changed

5-Not easy to oxidize for a long time

6-Layer material is PAg,AgNi,AgSnO2,AgSnO2ln2O3,AgCdO,AgZnO etc,base material is Copper.

Red Copper T2Y2 Strip material characteristics:

1-Red Copper T2Y2 is Copper-silver alloy,Cu+Ag≥99.9%;

2-Semi-hard state,tensile strength 245~345(MPa),Elongation ≥8%,Vickers hardness 80~110Hv;

3-Conductivity ≥56Ms/m, resistance ≤0.0178x10-6 Ω.m,Density: 8.9 g/cm³;

4-Good electrical conductivity,thermal conductivity,corrosion resistance and processing properties, can be welded and brazed.

we are leader supplier of Bimetallic Contact Rivet in this field in China,and we are factory,have the best price,can supply the Ex-works for our customers.We have been professional in manufacturing Bimetallic Rivet Contact for more than 20 years in China.As well known,the Bimetal Silver Contacts price is changeable according to the silver raw material price in market,it will make buyers confused and difficult to make sure how operate purchasing plans for Bimetallic Silver Contacts . But we have our own Silver Alloy Contact raw material factory,have a lot of silver and copper material in store,so we have strong risk-resisting ability to give our customers the best and Ex-works price.

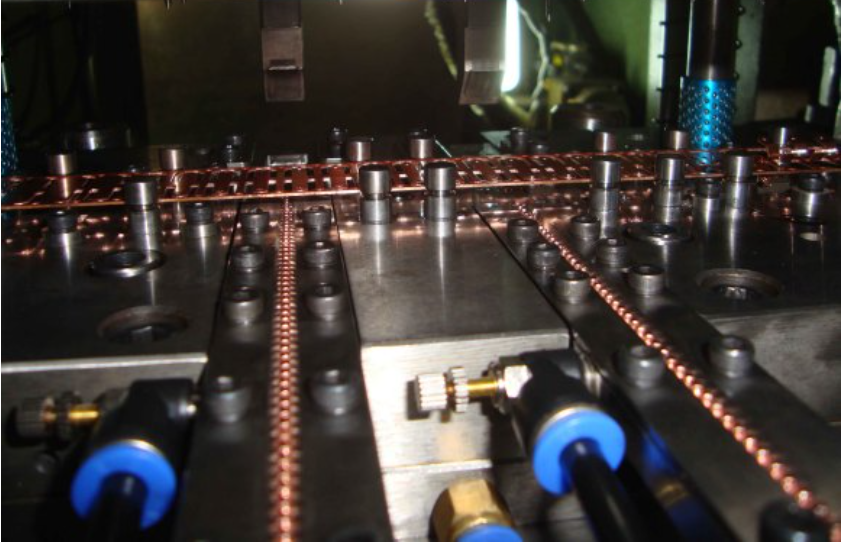

Metal Custom Copper Stamping process sequence:

1-Punching: The stamping process (including punching, blanking, trimming, cutting, etc.) that separates the sheet.

2-Bending: The stamping process of bending the Red Copper Sheet into a certain angle and shape along the bending line.

3-Deep drawing: Copper Stamping Parts process that transforms a flat sheet into various open hollow parts, or further changes the shape and size of the hollow parts.

4-Fine blanking: For products with high blanking precision, products with high requirements on size and surface light can be achieved through fine blanking molds to meet the requirements of the drawings.

5-Local forming: the Copper Stamping process (including flanging, bulging, leveling and shaping processes, etc.) that uses various local deformations of different properties to change the shape of the blank or stamping part.

Process requirements for electroplating of Copper Stamping Parts

1. There should be good bonding force between the plating layer and the base metal Precision Copper Stamping Parts, between the plating layer and the plating layer;

2. The coating should be finely crystallized, smooth and uniform in thickness;

3. The coating should have a specified thickness and as few pores as possible;

4. The plating layer should have the specified indicators, such as brightness, hardness, conductivity, etc.;

5. The plating time and the temperature of the plating process determine the thickness of the plating layer. The ambient temperature is -10℃~60℃;

6. The input voltage is 220V±22V or 380V±38V;

7. The maximum operating noise of water treatment equipment should not be greater than 80dB(A);

8. The relative humidity (RH) should not be greater than 95%;

9. The COD content of raw water is 100mg/L~150000mg/L.

What is the effect of silver plating on copper surface

1-Reduce resistance and avoid rust;

2-Prevent oxidation of the copper layer and reduce electrical conductivity;

3-Bare copper is easy to oxidize. After silver plating, oxidation can be reduced and oxidation resistance can be improved;

4-It can also increase the weldability and is easy to weld.

Advantages of silver plating on Metal Stamping Parts Electric Copper surface:

1-Silver is the best conductive conductor, and the conductivity of the substrate can be improved after silver plating;

2-Silver inherently has characteristics that make it resistant to microbes and bacterial growth; making items coated safer and more hygienic to use;

3-Silver is resistant to corrosion which helps to extend the life of the plated item Copper Stamping Parts;

4-Silver has the highest degree of optical reflectivity of any metal which makes it ideal for items such as medical lasers;

5-Silver is one of the least expensive precious metals and choosing it over other precious metals, such as gold or palladium, can save you quite a bit of money.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !