2-Base Material: Red Copper T2Y2 Stamping Part

3-Riveted Silver Contacts: Silver Solid Rivet,Copper Solid Rivet,Bimetal Silver Contact,Trimetal Contact Rivet,etc

4-Surface Plating:No plated or as require Silver-plated.

5-OEM/ODM:Accepted,need your drawing

6-Free Samples:10-50pcs is allowed

7-Lead Time:Samples 25-30days,Orders 7-10days(including the tooling/die production of Copper Stamped Part)

8-Production Capacity:50,000,000 pcs/month

9-Packing:Inner plastic bag/box,Outer carton/pallet

10-Payment Item:T/T,L/C by USD/EUR/RMB

11-Quality Standard:ISO9000,IATF16949,RoHS,REACH

12-Application:Relay,Contactor,Switch,Thermostat,Breaker,other High/Low-voltage electrical appliances.

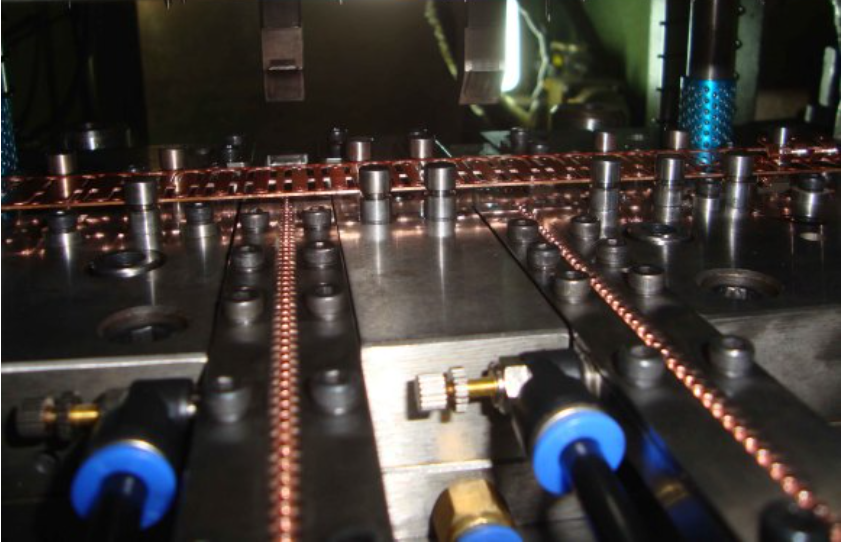

The process of In-die Riveting Silver Contacts

The process steps of the riveting of the silver contact riveting terminal in the mold: Contact Point progressive die punching brake reed → moving reed pickling → riveting Electrical Silver Contacts → bending of the Moving Spring Contact Assembly. Due to the large production volume of this product, in order to improve Production efficiency, stable product quality, and reduce production costs. The new process route formulated is: progressive die with material to produce moving reed strip → strip cleaning → strip riveting Electrical Silver Contacts and forming.

The technical requirements for the riveting of in-die silver contact riveting terminals: to achieve good in-mold riveting, the machining accuracy of mold parts is extremely high, oil cutting, PG, JG and other high-precision processing equipment are required; at the same time, the vibration plate and the mold are required. and the requirements for the gap and segment difference of the riveted Silver Contact Point and shrapnel are very high.

Introduction to electroplating process of Custom Copper Stamping

The electroplating process is a method of laying a layer of metal on a conductor using the principle of electrolysis. Electroplating refers to a surface processing method in which the base metal Copper Stamping to be plated is used as the cathode in a salt solution containing pre-plated metal, and the cations of the pre-plated metal in the plating solution are deposited on the surface of the base metal Electrical Copper Stamping Parts through electrolysis to form a plating layer.

The coating performance is different from the base metal Metal Stamping Parts Electric Copper and has new characteristics. According to the function of the coating, it is divided into protective coating, decorative coating and other functional coatings.

During electroplating, the plated metal Copper Stamping Parts or other insoluble materials are used as the anode, the workpiece to be plated is used as the cathode, and the cations of the plated metal are reduced to form a coating on the surface of the workpiece to be plated. It can enhance the corrosion resistance of metals Copper Strip Stamping (corrosion-resistant metals are mostly used for coating metals), increase hardness, prevent abrasion, improve conductivity, smoothness, heat resistance and surface aesthetics.

Process requirements for electroplating of Copper Stamping Parts

1. There should be good bonding force between the plating layer and the base metal Precision Copper Stamping Parts, between the plating layer and the plating layer;

2. The coating should be finely crystallized, smooth and uniform in thickness;

3. The coating should have a specified thickness and as few pores as possible;

4. The plating layer should have the specified indicators, such as brightness, hardness, conductivity, etc.;

5. The plating time and the temperature of the plating process determine the thickness of the plating layer. The ambient temperature is -10℃~60℃;

6. The input voltage is 220V±22V or 380V±38V;

7. The maximum operating noise of water treatment equipment should not be greater than 80dB(A);

8. The relative humidity (RH) should not be greater than 95%;

9. The COD content of raw water is 100mg/L~150000mg/L.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !