Production range for Pure Tungsten Contact and Tungsten Disc

1-Tungsten content: ≥99.95%

2-thickness: H0.50mm or more,

3-Diameter: Φ2.00mm-10.00mm,

4-Spherical surface: SR13mm-50mm.

6-High specific gravity alloy: weight 0.02g-200g,

6-Size tolerance: ±0.02mm-±0.06mm,

7-Roughness: ≤0.04um

8-Tungsten Contact type: Flat, Radius,Ventilated,Collar,Screw

Physical and mechanical properties of Motorcycle Horn Tungsten Rivet materials In order to meet user requirements, technicians have done a lot of work. For the splitting, brittle fracture, and uneven grain size of the cross-section during the production process of the Solid Tungsten Contact Rivets material, the rod diameter is the same. The reasons why the O degree and flatness can’t meet the requirements are comprehensively analyzed, and a series of measures are taken pertinently.

What's the Pure Tungsten Contact and Application ?

Tungsten Rivet or tungsten contact can be made from tungsten rod or tungsten disk.Tungsten point/contacts are for use in high voltage applications, usually where highly repetitive switching is required. Tungsten has a melting temperature of 3,380℃ which gives it excellent arc-erosion resistance.Tungsten may develop troublesome oxide films, especially when used as the anode contact in some DC applications. Therefore, pure tungsten is often used as the cathode contact, and a palladium alloy used as the anode contact. Such a combination also minimizes contact interface resistance and material transfer.

Working principle and failure analysis of Tungsten Contact Car Horn

Tungsten Contact Car electric horns rely on the vibration of metal diaphragms to produce sound. The car electric horn is composed of an iron core, a magnetic coil, a Tungsten Contact Rivet, an armature, and a diaphragm. When the driver presses the horn switch, the current passes through the coil through the Copper Tungsten Contact, the coil generates a magnetic force to attract the armature, forcing the diaphragm to move, the armature moves to disconnect the Tungsten Copper Electrical Contact, the current is interrupted, the magnetic force of the coil disappears, and the diaphragm is elastic and spring. Under the action, it returns to its original position together with the armature, the Tungsten Contact Rivets closure circuit is turned on again, the current flows through the Solid Tungsten Contact Rivets through the coil to generate a magnetic force, and the above actions are repeated. In this way, the diaphragm vibrates continuously, thus making a sound. The soundboard is rigidly connected with the diaphragm, which can make the vibration smooth and sound more pleasant (ie the principle of electromagnet).

Line faults are mainly virtual connections, such as loose horn plug terminals, ablation of Car Horn Tungsten Contact Rivets of horn relays, poor contact of horn switches at the steering wheel, etc. But in many horn failures, especially in winter, the problem is the failure of the horn itself.

Combined with our use environment and other factors, the failure of the speaker itself is mainly due to the following reasons:

1. Pure Tungsten Contact ablation: If you press the horn for a long time, it is easy to cause the Tungsten Point Contact of the horn to ablate and generate impedance, the current flowing through the electromagnetic coil is weakened, and the decrease in electromagnetic suction cannot attract the armature to drive the diaphragm to vibrate normally, resulting in hoarseness or even no sound. . However, when the horn is continuously honked, if the instantaneous strong current passes through the impedance, it can still work normally, so it will be good and bad.

2. The seal is not tight and it is easy to get wet: Although the inside of the horn is airtight, if the air is not tightly sealed when the car washes into the mist or there is water vapor in the air in the interior space, the water vapor can easily cause the Tungsten Steel Contact to get wet and not work properly.

3. Poor contact of electromagnetic coil terminals: Some horn internal electromagnetic coil enameled wire terminal joints are connected by aluminum metal rivet crimping, not reliable welding connection, if the insulating paint on the enameled wire at the end is not clean or the rivet crimping is not reliable, it is easy to produce Virtual connection failure, resulting in poor speaker operation. This kind of failure is due to the quality of the speaker, which cannot be repaired, and can only be replaced with new parts.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

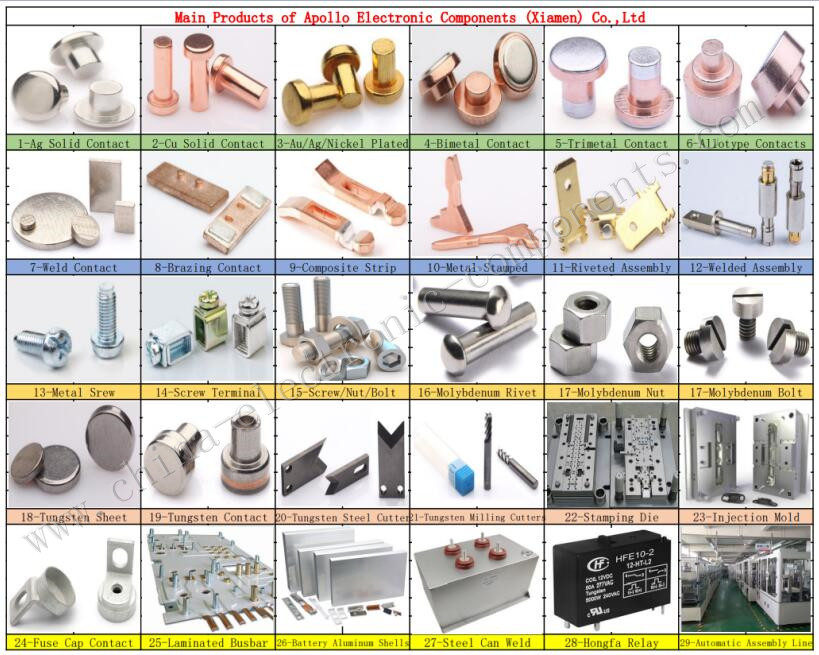

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !