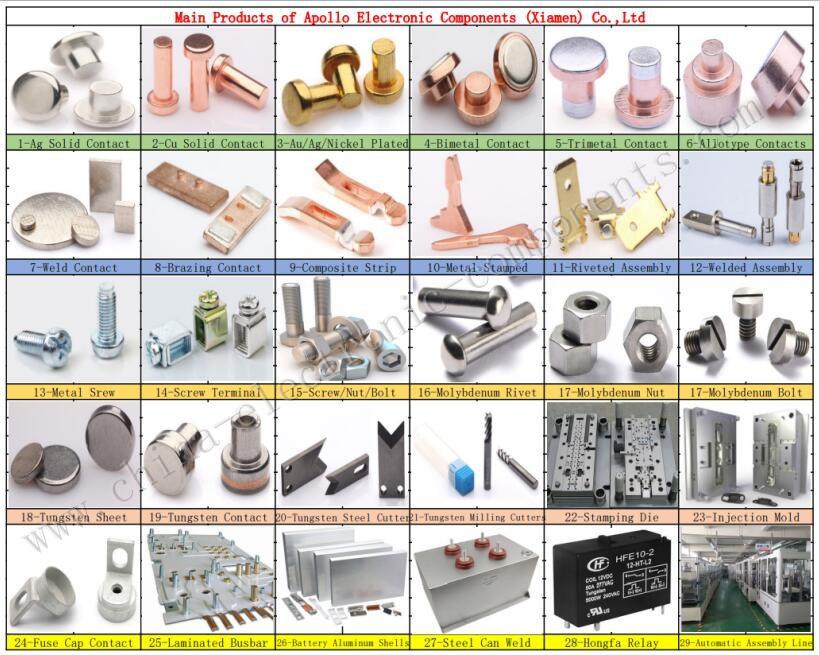

Production range for Pure Tungsten Contact and Tungsten Disk

1-Tungsten content: ≥99.95%

2-thickness: H0.50mm or more,

3-Diameter: Φ2.00mm-10.00mm,

4-Spherical surface: SR13mm-50mm.

6-High specific gravity alloy: weight 0.02g-200g,

6-Size tolerance: ±0.02mm-±0.06mm,

7-Roughness: ≤0.04um

8-Tungsten Contact type: Flat, Radius,Ventilated,Collar,Screw

Tungsten Steel Contact is the contact point used to make or break the circuit in the switch. It is widely used in the contacts of AC contactors, automobiles, motorcycles, electric horns, magneto and other electrical products.We have five production lines for making Wolfram Copper Contact Rivets 150 million pcs monthly.

Tungsten contact rivet parameter

1-Processing technology: heat welding for tungsten round coin and copper alloy rivet.

2-Normal contact rivet's head diameter size: Φ1.00mm-15.00mm

3-Main material:W/Cu,W/Iron,etc.

4-Contact shape: rivet type.

5-Surface treatment:nickel plating or no.

6-Weather resistance

7-Easy to install

8-Robust construction

What’s the Tungsten Contacts of Electrical Appliances?

As far as most electrical equipment is concerned, they use high-purity tungsten contacts as contact points, mainly because the Tungsten Contacts for Electrical Appliances have a high melting point, a small evaporation rate, and good electrical and thermal conductivity. Features. Tungsten Point Contact made with metal tungsten have a longer cycle life than conventional contacts, while ensuring good circuit board contact.

At present, common control electrical products such as AC contactors, electromagnetic relays, electrical switches and air switches contain electrical contacts, and Electric contacts are one of the most important components of these products. The reliability and service life of a product largely depend on the contact performance, which is affected by factors such as the contact material, load type, contact pressure, operating frequency, and use environment. When these factors cannot meet the working requirements, there will be problems such as electrochemical corrosion of contacts, welding between contacts, contact wear, and increase in contact resistance, which will lead to unreliable operation, functional failure and even potential safety hazards.

In the energized state, if the current to open the circuit exceeds a certain limit, or if the voltage across the contact gap after disconnection exceeds a certain limit, a yes will occur in the contact gap. Under the action of a strong electric field, the gas between the contacts will discharge, and sparks and strong light will be generated and emitted with the increase of temperature. The arc will corrode the metal surface of the contact, shorten the service life of the electrical appliance, prolong the breaking time of the circuit, and cause the contact of the contact to fail. In severe cases, it can also lead to fire accidents.

Today, in order to further improve the overall quality of electrical equipment contact points, most manufacturers use metal pure tungsten to manufacture electrical contacts.

Characteristics required by the Tungsten Contact during using:

1. The contact resistance is low and stable;

2. Good welding resistance and complete opening and closing;

3. Good conductivity;

4. The wear resistance is good, and the Tungsten contact surface can’t be changed.

1. Tungsten Contact Rivets Processing Requirements

With the continuous development of the automobile manufacturing industry, the requirements for tungsten contact materials are rapidly increasing. The user's requirements for tungsten contact materials are:

(1)Rod without cracks, scratches, smooth surface;

(2)Fine and uniform cross-section grains, short fibers;

(3)Good straightness, concentricity and roundness;

(4)High hardness, good impact toughness;

(5)Vapor pressure Low evaporation rate, small thermal expansion coefficient;

(6)Good and stable arc resistance.

Physical and mechanical properties of Motorcycle Horn Tungsten Rivet materials In order to meet user requirements, technicians have done a lot of work. For the splitting, brittle fracture, and uneven grain size of the cross-section during the production process of the Solid Tungsten Contact Rivets material, the rod diameter is the same. The reasons why the O degree and flatness can’t meet the requirements are comprehensively analyzed, and a series of measures are taken pertinently.

2. Electrical Tungsten Contact Rivets Material Characteristics

Tungsten is used as electrical contact or contact material, which is resistant to arc ablation; good fusion resistance; metal surface evaporation caused by electrothermal action, less transfer and consumption; strong current interrupting ability; and good wear resistance, dynamic hit performance. Compared with other metal or alloy materials, the price is low, so tungsten contacts and tungsten wafers are widely used in various fields of industry, agriculture, technology and defense.

Solid Tungsten Contact Rivets is characterized by its advantageous properties of high melting and boiling points, sufficient electrical and thermal conductivity and high hardness and density .Industrial Tungsten Brazed Contacts Rivets are mainly used in the form of brazed contact tips for switching duties that require a rapid switching sequence such as Car Horn Tungsten Contact Rivets for cars and trucks.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !