What’s the Side Composite Strip of Fuse melt and manufacturing method thereof ?

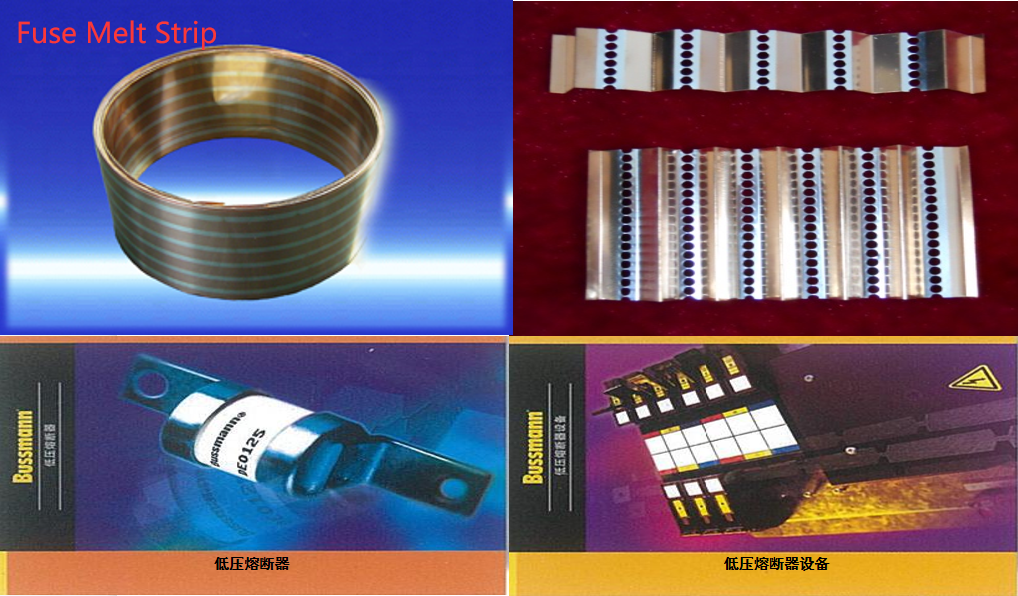

A fuse is an electrical component that uses a metal conductor as a melt to be connected in series in a circuit. When an overload or short-circuit current passes through the melt, it fuses due to its own heat, thereby breaking the circuit and protecting electrical equipment and the power grid. The melt Side Composite Strip of Fuse is the key element to control the fusing characteristics, and the Fuse Melt Strip material, size and shape determine the fusing characteristics. Fuse Melting Strip materials are divided into two types: low melting point and high melting point. Low melting point materials such as lead and lead alloys have a low melting point and are easy to fuse. Due to their large resistivity, the cross-sectional size of the Silver Strip for Fuse Core is larger, and more metal vapors are generated during fuse. It is only suitable for fuse with low breaking capacity. Device. High melting point materials such as copper and silver have high melting points and are not easy to fuse, but due to their low resistivity, at a certain resistance, the required cross-sectional area is small and the metal vapor generated during fuse is less, which is beneficial to extinguishing the arc and is suitable for For fuses with high breaking capacity.

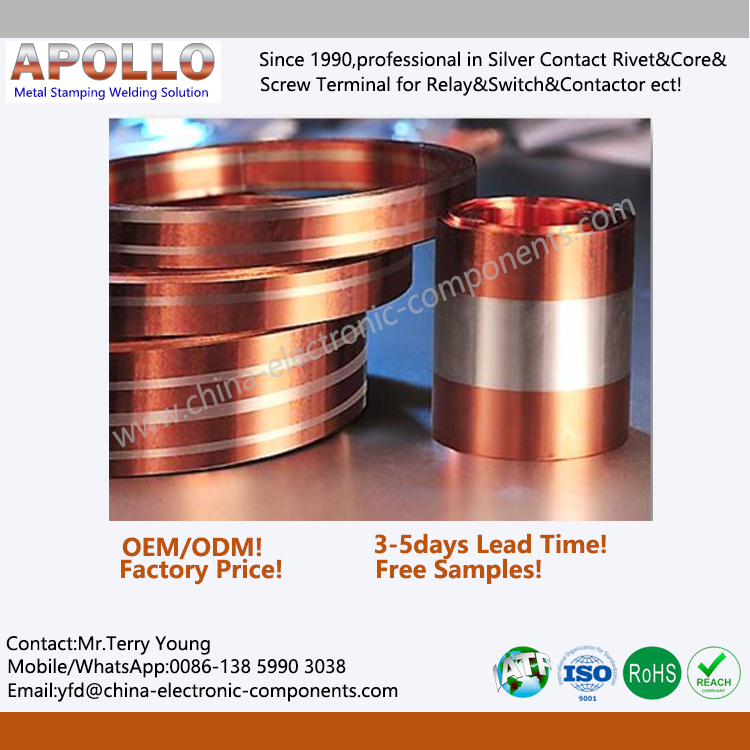

Pure Silver melt has a good ability to break strong short-circuit currents, and silver has stable chemical properties, excellent oxidation resistance and corrosion resistance. The resistance value is not easy to change during use, and the melting point is constant, which is beneficial to maintain the stability of the circuit. Performance and safety are the key materials for high-current, high-reliability fuses. However, due to the high price of silver melt, the cost of using silver melt is high.The use of silver or silver alloy in the fuse protection part of the fuse can ensure that the resistance value of the fuse protection part of the Fuse Silver Melting Strip is not easy to change when the strong short-circuit current is interrupted, and the melting point is constant, which is beneficial to maintain the stability and safety of the circuit The characteristic of sex, guarantees the fuse characteristic that the fuse itself should have, and does not affect the safety of electrical appliances and circuits.

Fuse Link Melt materials are divided into two types: low melting point and high melting point. Low melting point materials such as lead and lead alloys have a low melting point and are easy to fuse. Due to their large resistivity, the cross-sectional size of the melt is larger, and more metal vapors are generated during fuse. It is only suitable for fuse with low breaking capacity. Device. High melting point Fuse Melt Strip materials such as copper and silver have high melting points and are not easy to fuse, but due to their low resistivity, they can be made into a smaller cross-sectional size than low melting point melts, and produce less metal vapor during fuse, which is suitable for high breaking Capable fuse. The shape of the Side Composite Strip of Fuse is divided into two types: filament and ribbon. Changing the shape of the variable cross-section can significantly change the fusing characteristics of the fuse. The fuse has a variety of different fusing characteristic curves, which can be adapted to the needs of different types of protection objects.

Competitive advantages of Copper Silver Alloy Composite Strip:

Silver metal oxide/copper/iron & nickel (AgMeO/Cu/Fe&Ni) three-layer composite strip:

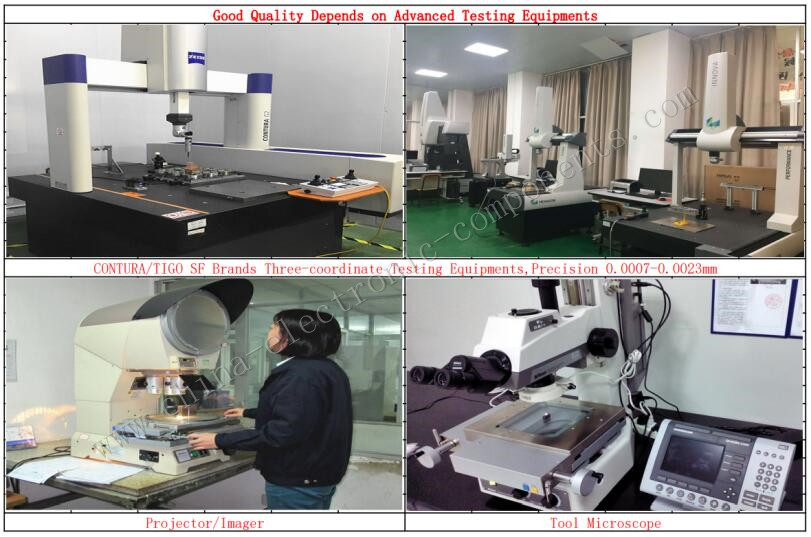

(1)Technical advantages: The project AG/Cu Clad Strip is based on the company’s invention patents for processing and production processes, using high-temperature solid-phase composite rolling production technology, heated to a temperature above the metal recrystallization temperature in a protective atmosphere, and completed under the effect of rolling deformation Rolling and compounding of different metals, with independent core technology, currently there are only a handful of manufacturers capable of producing three-layer metal composite strip, and our Copper/Brass Silver Overlay is a leading position in China;

(2) Product performance advantages: The project product Silver Alloy Strip uses silver metal oxide (AgMeO) instead of the traditional material silver metal cadmium oxide (AgCdO), which combines the excellent electrical properties and oxidation resistance of silver metal oxide and the good physical and mechanical properties of copper. Performance, as well as the excellent welding performance of iron, form a superior comprehensive performance (electrical contact performance and mechanical performance).All technical indicators have reached the company’s design requirements, with excellent performance, and comply with the EU RoHS Directive and my country’s "Administrative Measures for the Prevention and Control of Environmental Pollution by Electronic Wastes". All environmental indicators of the affected exhaust gas, waste water and waste residue meet the requirements of the environmental protection department;

(3) Leading industry level: the project product silver metal oxide/copper/iron & nickel (AgMeO/Cu/Fe&Ni), and break the technological monopoly of foreign counterparts in the production of such materials, and solve the high procurement cost of the majority of users. Long cycle and other issues, while filling the gaps in this domestic technology of Silver Copper Composite Sheet.

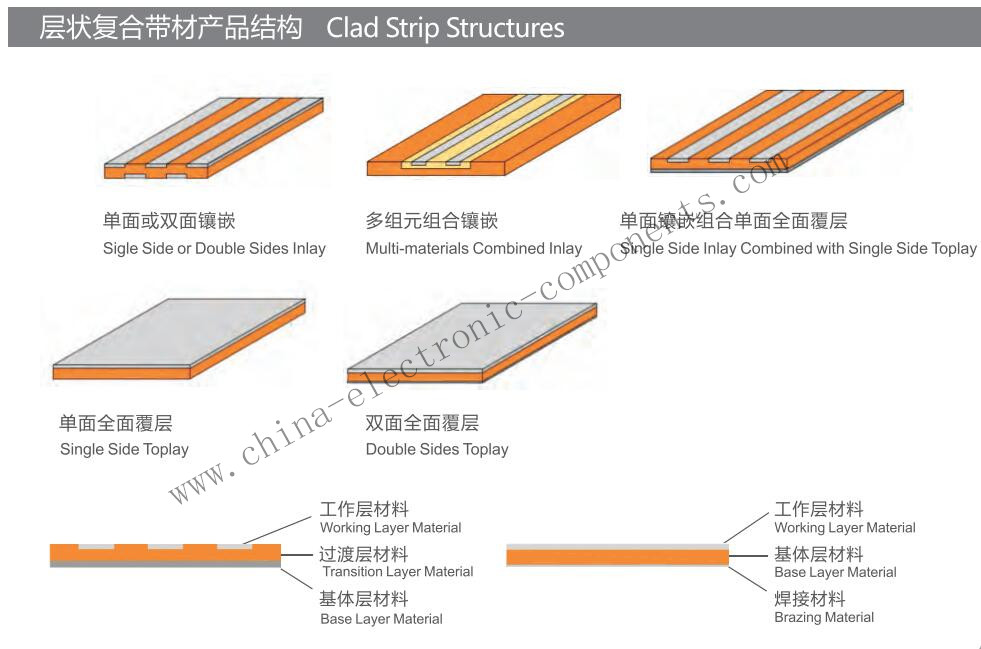

Precious Clad Metal is a new technical material, based on different industry needs, formed by advanced indoor temperature composite technology or Hot Composite Technique; Silver Inlay and Precious Metal Clad is rolled with different characteristic material strips composite alloy material and base material strip. Their alloy and base material characteristic are well preserved, and the Mid Inlay Clad Metal compound characteristic are very good, esp. The Silver Copper Alloy Strip electrical character and its wearability are much better than single precious metal contact material (such as gold and silver ) . Beside, It is a saving of precious metal, keeping low cost and consistency of social development.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !