Bimetal Strip Ag/Cu Technology evolution:

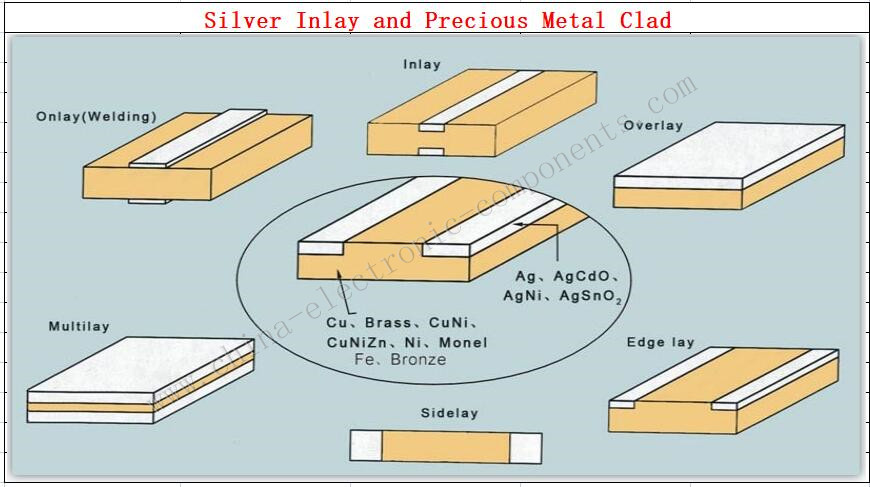

The surface material is changed from the original pure silver and silver nickel to silver cadmium oxide and silver tin oxide.The inlay method of the surface material has been increased and improved from the initial full-back inlaying to partial inlaying;

The base material is improved from copper to copper-iron or copper-iron-copper;

The composite processing technology is improved from thermal composite to roll welding.

This series of changes can not only greatly increase the service life of materials and components, but also reduce the use of rare and precious metal silver under the condition of ensuring the performance. This fundamentally alleviates the problem of difficult and high-cost purchases for the majority of users,like Bimetallic Strip Thermostat,Bimetallic Strip Circuit Breaker,Side Composite Strip of Fuse etc. and at the same time has improved the level of domestic metal composite technology, promoted the development of my country's electrical and electronic products and other temperature control industries, and created obvious social and economic benefits for the country.

Determination of the composite strength of silver-copper composite strips in China(GB/T 15159-2008/)

A.1 This appendix is applicable to the bonding firmness of the composite and mosaic composite materials of the testing surface and the matrix

A.2 Test of the firmness of the combination of the composite layer and the substrate

A.2.1 Sample preparation

According to the number of samples specified in the standard, randomly cut Electrical Contacts strip samples with a width greater than 4mm in the rolling direction from the finished product to make test samples.

A.2.2 Sample device

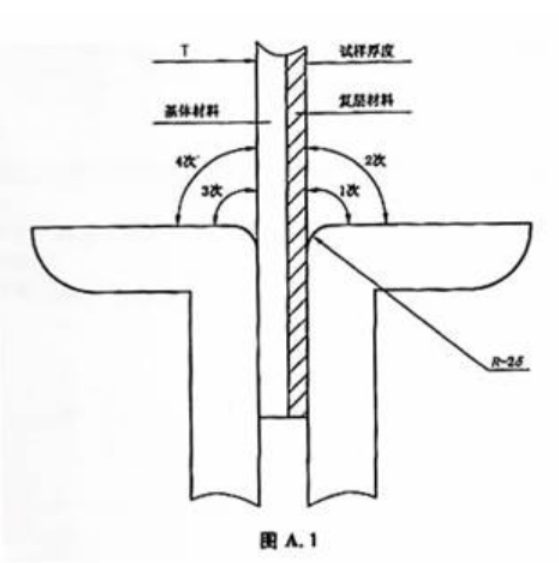

The test device should be able to effectively clamp one end of the sample, and the other end can be used for 90° bending, with a bending radius R≥2t (t is the thickness of the sample)

A.2.3 Test method

The fastness test method is shown in A.1.

A.2.4 Principle

The composite silver copper material undergoes back-and-forth bending and receives stress in the opposite direction, which promotes its delamination. If it is not delamination, it is strong enough.

A.2.5 Judgment

After the sample Silver Copper Alloy Strip has been bent 4 times, use a 7-fold magnifying glass to check the bent part. The two-layer bonding surface is qualified if there is no opening and delamination, otherwise it is unqualified.

A.3 Test of the firmness of the bond between the edge of the composite strip and the base of the Precious Clad Metal composite strip

A.3.1 Sample preparation

According to the number of samples specified in the standard, randomly cut Silver Clad Copper Strip samples with a width greater than 4mm from the finished product perpendicular to the rolling direction to prepare samples.

A.3.2 Test device

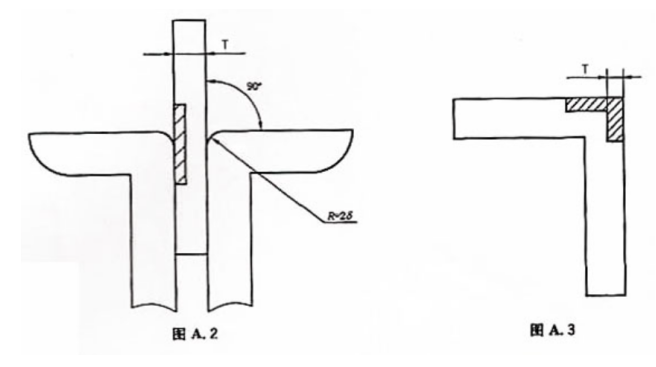

Same as A.2.2

A.3.3 Test method

The fastness test method is shown in Figure A.2 and Figure A.3.

A.3.4 Principle

After the Copper Silver Alloy Composite Strip material is bent back and forth, it is subjected to stresses in the opposite direction, which promotes its delamination. If AG/Cu Clad Strip is not delamination, it is strong enough.

A.3.5 Judgment

After the sample Silver Alloy Strip is bent at 90°, the edge of the strip and the matrix are split and layered as unqualified.

A.3.6 Apparatus and equipment

The test device can be manufactured according to the above-mentioned diagram.

Competitive advantages of Copper Silver Alloy Composite Strip:

Silver metal oxide/copper/iron & nickel (AgMeO/Cu/Fe&Ni) three-layer composite strip:

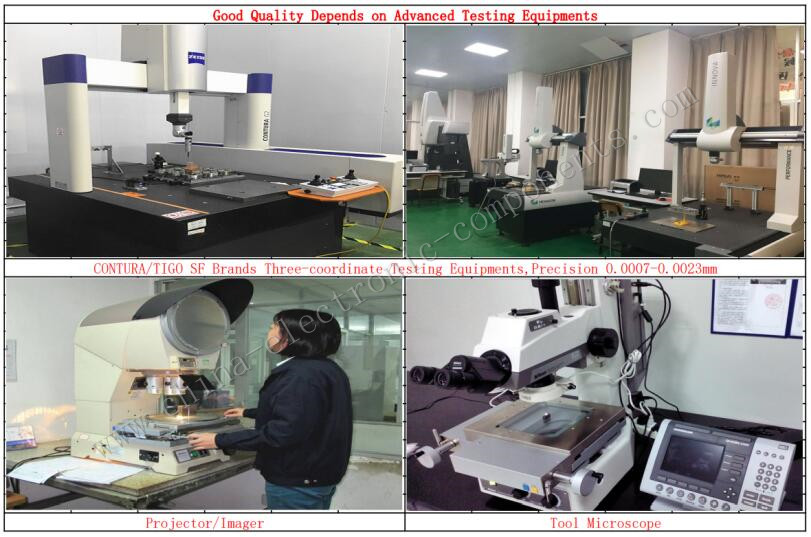

(1)Technical advantages: The project AG/Cu Clad Strip is based on the company’s invention patents for processing and production processes, using high-temperature solid-phase composite rolling production technology, heated to a temperature above the metal recrystallization temperature in a protective atmosphere, and completed under the effect of rolling deformation Rolling and compounding of different metals, with independent core technology, currently there are only a handful of manufacturers capable of producing three-layer metal composite strip, and our Copper/Brass Silver Overlay is a leading position in China;

(2) Product performance advantages: The project product Silver Alloy Strip uses silver metal oxide (AgMeO) instead of the traditional material silver metal cadmium oxide (AgCdO), which combines the excellent electrical properties and oxidation resistance of silver metal oxide and the good physical and mechanical properties of copper. Performance, as well as the excellent welding performance of iron, form a superior comprehensive performance (electrical contact performance and mechanical performance).All technical indicators have reached the company’s design requirements, with excellent performance, and comply with the EU RoHS Directive and my country’s "Administrative Measures for the Prevention and Control of Environmental Pollution by Electronic Wastes". All environmental indicators of the affected exhaust gas, waste water and waste residue meet the requirements of the environmental protection department;

(3) Leading industry level: the project product silver metal oxide/copper/iron & nickel (AgMeO/Cu/Fe&Ni), and break the technological monopoly of foreign counterparts in the production of such materials, and solve the high procurement cost of the majority of users. Long cycle and other issues, while filling the gaps in this domestic technology of Silver Copper Composite Sheet.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !