1-Products Name: Electrical Brazing Welded Silver Contacts

2-Brand Name: XIAMEN APOLLO

3-Country of Origin: XIAMEN CHINA

4-Face Material: Pure Silver(99.99%), Fine Silver(AgNi0.15), AgCdO, AgSnO2, AgSnO2In2O3, AgNi, etc

5-Base Material: Red Copper

6-Surface Plating: No plated or as require Silver-plated

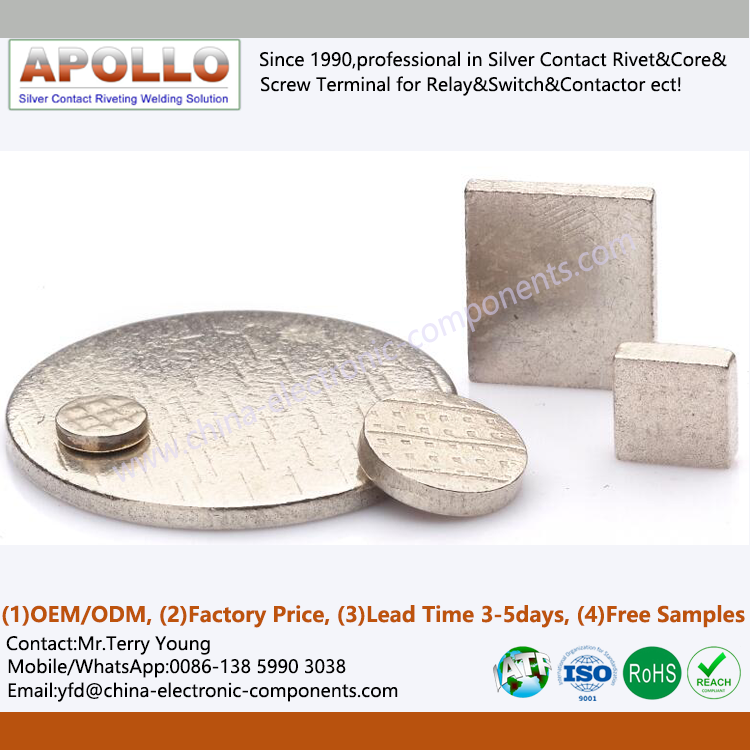

7-Welded Silver Contacts Styles:

Electrical Contacts Buttons Alloy

Silver Contact Tips Alloy

Composite Weld Contacts - Radius Faced

Composite Weld Contacts - Flat Face

8-OEM/ODM: Accepted,need your drawing

9-Free Samples: 10-50pcs is allowed

10-Lead Time: Samples 20-30days,Orders 7-15days

11-Production Capacity: 30,000,000 set/month

12-Packing: Inner plastic bag/box,Outer carton/pallet

13-Payment Item: T/T,L/C by USD/EUR/RMB

14-Quality Standard: ISO9000,IATF16949,RoHS,REACH

15-Application: Relay,Contactor,Switch,Thermostat,Breaker,other High/Low-voltage electrical appliances

Characteristics of Our Products Electrical Contact Resistance Brazing

1-Durability of electric abrasion

2-Low and stable connect resistance

3-High stability when working

4-Prevent oxidized when exposure to the air

5-Less and even electrolytic corrosion

Silver Contact Welding process problems and solutions

1. The influence of welding current

Electric current has a greater influence on heat generation than both time and pressure. Therefore, in the Welded Contacts welding process, the current parameter output must be strictly controlled. If the Contact Welding welding current is too small, the nucleus cannot be formed or the size of the nucleus is small, and the Electrical Contact Welding welding joint strength is small; if the welding current is too large, the surface and back of the silver contact will be black and the indentation will be too deep.

2. The influence of welding time

In order to ensure the strength of the silver contact solder joints, the welding time and welding current can complement each other within a certain range. In order to obtain a certain strength of the Brazing Electrical Contacts, but also to ensure the beauty of the Brazed Electrical Contacts, high current and short time can be used.

3. The influence of electrode pressure

The electrode pressure has a significant effect on the total resistance between the two electrodes Welding Electrical Contacts. The electrode pressure is small and splashing is easy to occur. As the electrode pressure increases, the total resistance decreases. When the electrode pressure increases and the welding current remains the same, it cannot compensate for the decrease in heat generation caused by the decrease in total resistance. Therefore, the strength of the Electrical Contact Resistance Brazing decreases with the increase in welding pressure. The solution of Resistance welding Contacts is to increase the pressure At the same time, increase the welding current.

4. The influence of electrode shape and material properties

Since the contact area of the electrode determines the current density, the resistivity and thermal conductivity of the electrode material are related to the generation and loss of heat. Therefore, the shape and material of the electrode have a significant influence on the formation of the nugget. With the deformation and wear of the electrode tip, the contact area increases, and the strength of the Silver Contact Welding will decrease. Pay attention to the maintenance and repair of the electrode (spot welding head) during use. When soldering the Welded Electrical Contact, first consider the stickiness of the solder joints. It is recommended to use tungsten steel electrodes; the soldering contact points are also particularly important. The upper and lower electrodes must be kept flat, otherwise it is easy to cause indentation. If the welding efficiency is too fast, the electrode head is likely to cause heat accumulation. It is recommended that the electrode head be filled with cold water.

Mr.Terry Young (Sales Manager&Technology Engineer)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor&Breaker ect Riveting&Welding solutions !