Characteristics of Our Products Electrical CuNi AgSnO Welded Contacts

1-Layer Material:Ag,AgNi,AgSnO2,AgSnO2ln2O3,AgCdO,AgZnO,etc

2-Base Material:Copper,CuNi,Fe

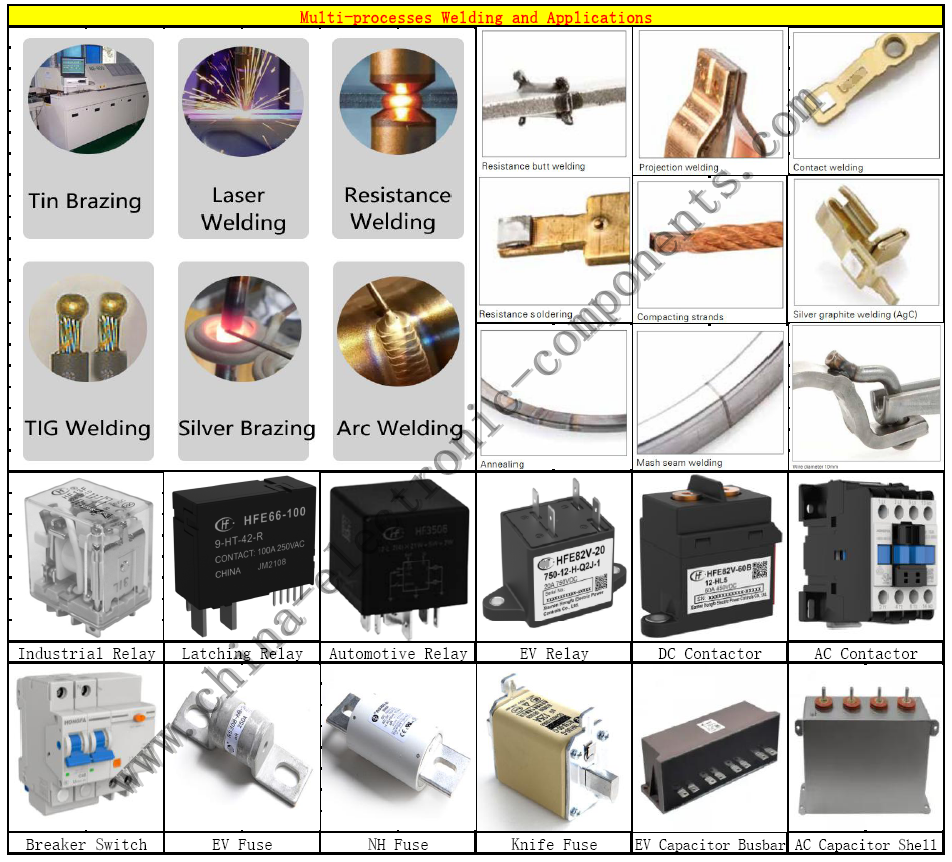

3-Application: Relays,Micro Switches,Thermostats,Buttons,Temperature Controllers,Circuit Breakers etc.

4-Durability of electric abrasion

5-Low and stable connect resistance

6-High stability when working

7-Prevent oxidized when exposure to the air

8-Less and even electrolytic corrosion

The CuNi AgSnO Welded Contacts is composed of three layers of metal. The working surface material is silver, fine-grained silver, silver nickel, silver tin oxide, silver tin oxide indium oxide, silver copper, silver zinc oxide, silver cadmium oxide, etc. The welding surface materials are CuNi, Fe, etc., such as fine-grained silver/copper/iron; silver nickel/copper/iron; silver tin oxide/copper/iron, etc. The welding surface is made of cold-rolled low-carbon steel or copper-nickel alloy with good welding performance, and is equipped with 5-7 plum or diamond points to fully ensure that the contact and the bimetal are welded firmly. It is widely used in relays, micro switches, thermostats, buttons, temperature controllers and circuit breakers.

CuNi AgSnO Welded Contacts Features:

1-The welding surface of the three-layer composite electric plum diamond contact is made of pure iron material with small bumps to increase the welding performance, which can make the electric contact and the bimetallic sheet and the stainless steel sheet and other iron-based alloys weld firmly.

2-The welding part is joined by molten metal, and the Special Electric Contact electrical stability is better than that of riveted contacts, and the positioning is good, and the welding is beautiful. If the riveting method is used, the bimetal is deformed due to the over-tight riveting, and the system resistance is increased due to the loose riveting. Will cause errors in the thermostat.

3-Compared with brazed silver contacts, the heating time is shorter and the working environment is clean. It is suitable for the joining and processing of small parts, especially for the occasions of micro-mechanism.

For three-metal composite contacts, different silver alloy materials can be selected according to the size of the electrical current passing through. It is suitable for pulse welding and contact bridge connection. It can prepare electrical contact parts and bimetal contact bridges. It is widely used in relays and micro switches. , Temperature controller, buttons, temperature controller and circuit breaker protector.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !