The Contact Tip Welding resistance value of the silver contacts under different pressures. As the pressure increases, the contact area between the Welding Electrical Contact and the silver plate continues to increase, and the contact resistance between the silver contacts should gradually decrease. The effect of pressure on the resistance of Electrical Contact Resistance Brazing: As the pressure continues to increase, the resistance value decreases in a fast and then slow manner: when the pressure increases from 10 N to 200 N, the resistance decreases linearly, and then the decline slows down. When the pressure reaches 1 kN or more, it gradually stabilizes, and when the pressure is 1.4 to 2.0 kN, there is basically no change in the Low Voltage Electrical Contacts resistance. Therefore, in order to obtain a more accurate Brazed Electrical Contacts resistance value, it should be measured at a pressure of >1.5 kN. Comparing the steady-state resistance values of Brazed Electrical Contacts with different brazing rates, it can be found that the resistance decreases as the brazing rate of Contacts Metals Welding increases, that is, the larger the soldered area, the better the conductivity of the silver contacts.

The characteristics of Silver Alloy Oxide Contact products are as follows:

1-The Contact Tip Welding products prepared by the alloy internal oxidation method have good material density, small oxidizing material points, arc corrosion resistance, and long electrical life.

2-Silver tin oxide, silver tin oxide indium oxide, silver zinc oxide, silver copper oxide, silver cadmium oxide and other contact products are added with trace elements such as nickel and rare earth. Low temperature and high pressure oxidation technology is adopted to achieve the effect of fine particle size and dispersion strengthening. , Improve the mechanical strength of the product Electrical Contact Welding, improve the welding resistance, arc burn resistance and electrical wear resistance of the Contacts Metals Welding.

3-Using smelting atomization, combined with pre-oxidation process, the Brazing Electrical Contacts grains are refined, the structure is uniform, the microstructure does not appear segregated, the oxide poor ridge area is eliminated, and the Brazed Electrical Contacts with excellent performance is manufactured.

Alloy oxide contact products are widely used in low-voltage electrical appliances, and the Welding Electrical Contact main uses are:

1-Silver tin oxide series Resistance welding Contacts:

The Brazing Electrical Contacts are suitable for medium and large capacity AC contactors (such as CJ20, CJ40, 3TF series, etc.), high-power AC switches (above 50kW), DC contactors, AC and DC power relays, and automotive electrical appliances And on the low-voltage circuit breaker of small and medium capacity.

2-Silver zinc oxide series Silver Contact Welding:

Electrical Contact Welding are mainly used in small and medium capacity low voltage circuit breakers with rated current within 200A (such as DZ15 series molded case circuit breakers, especially universal circuit breakers), as well as power protection switches, leakage protection switches, AC relays, DZ15L series leakage current Circuit breakers, etc., some large-capacity switches also use AgZnO materials Contacts Metals Welding, such as ME universal circuit breakers.

3-Silver cadmium oxide series Welded Electrical Contact:

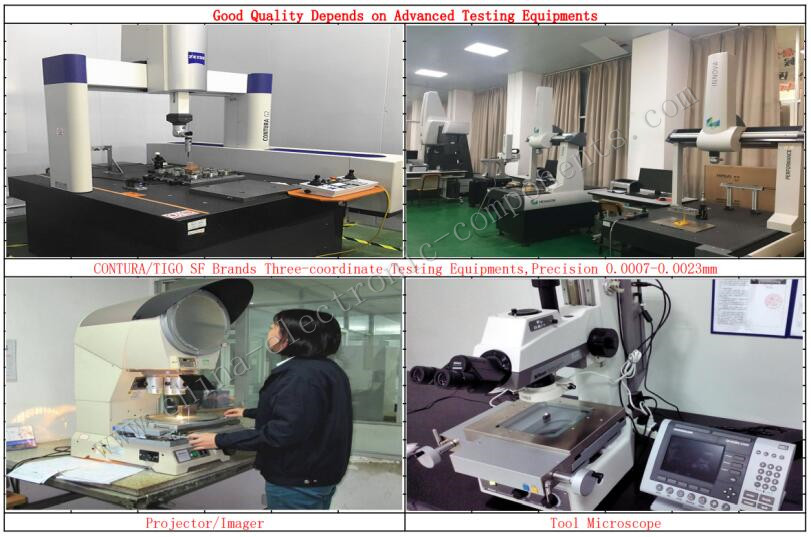

The Welded Contacts widely used in medium and large capacity relays, contactors, AC and DC switches and medium and small capacity circuit breakers, especially suitable for medium and large capacity AC contactors. For the production of silver metal oxide contact products Contact Welding, the existing production of intermediate frequency melting furnaces, hot rolling mills, finishing mills, automatic stamping machines, oxidation furnaces, isostatic presses, extruders, atomic absorption spectrometers, metallographic microscopes, etc., 150 sets of testing equipment can be developed and produced according to the specific requirements of users, with an annual production capacity of 320 tons.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

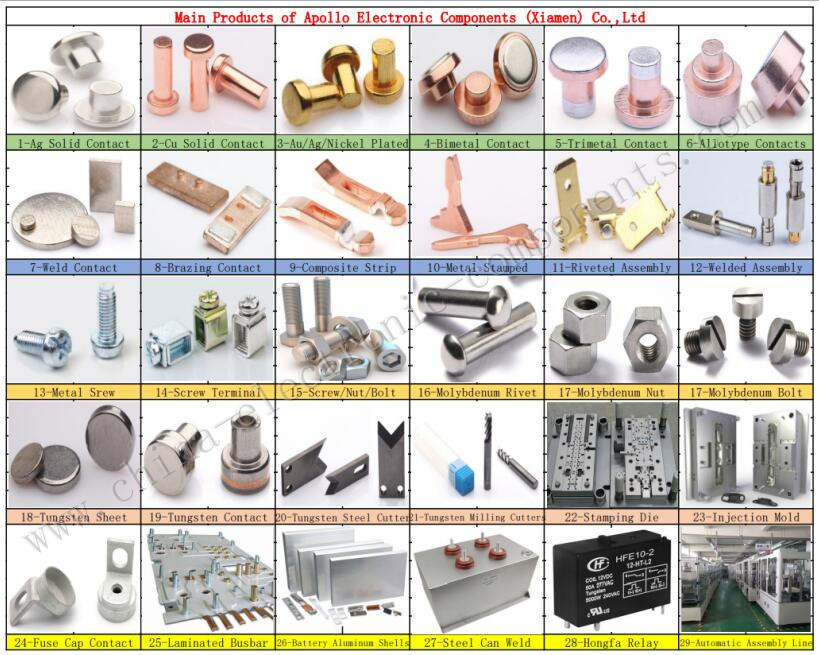

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !