Our products Electrical Silver Contacts Features:

1-Good conductivity

2-The contact resistance is low and stable

3-Good welding resistance and thorough opening and closing

4-Good abrasion resistance,the contact surface not changed

5-Not easy to oxidize for a long time

The Solid Silver Contacts refer to the intersection point where the electronic appliances are disconnected and contacted when they are opened and closed. Since the metal conductor terminal is prone to instantaneous heat and sparks at the moment of contact, the Silver Contact Point is prone to oxidation and electrolysis in the multi-frequency process of use, so the Silver Alloy Contacts is increased and thickened, or polymer metal is used Manufacturing (copper and silver are the most common materials), so this Solid Electrical Contacts made of polymer metal, or a point thickened with the same material is called Electrical Silver Contacts.

Silver Contact Rivets advantage:

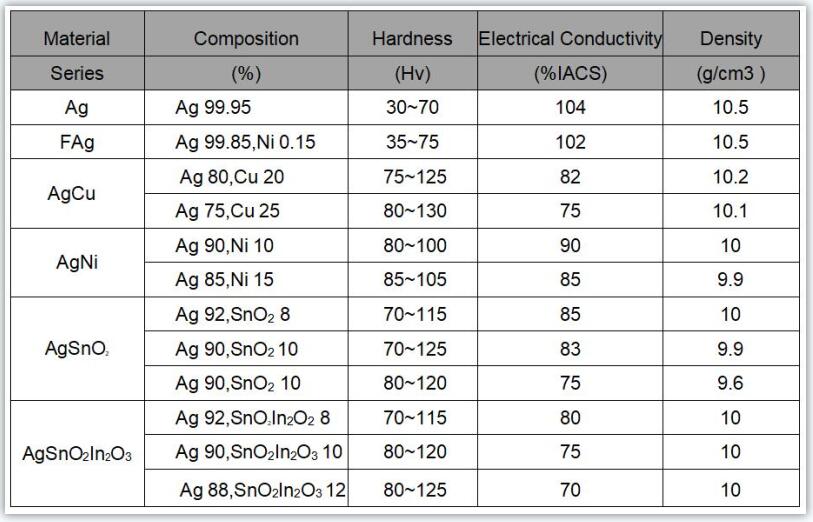

Pure Silver Electronic Contacts: best conductivity, but easy to stick and easy to solder.

AgCdo (silver-cadmium oxide) Electronic Contacts series: It has good wear resistance, welding resistance and electrical and thermal conductivity, and the contact resistance is small and stable.

AgSno (silver-tin oxide) Electronic Contacts series: high thermal stability, heat resistance, arc erosion resistance and melting resistance, long service life.

AgNi (silver-nickel) Electronic Contacts series: when used for direct current contacts, it has good electrical and thermal conductivity, low contact resistance and stable surface, and electrical loss is small and uniform.

AgSnOlnO (Silver-Indium Tin Oxide) Electronic Contacts series: It has better thermal stability and higher hardness, and has better weldability and durability.

How to deal with the large Electrical Contact Point resistance in the relay to make it smaller?

It can be judged based on the manufacturer's sample. Generally this value is less than 100mΩ. But if the relay is left for too long, the resistance value of the Silver Electrical Contact will increase, but this increase only needs to load a 1~3A current for a while. It cannot be regarded as a failure. When the contact passes the AC current, because the current will have a zero-crossing point (2 times a week), when the current crosses zero, its arc energy is the smallest, and it is easy to extinguish the arc and make the Electrical Contact Rivet shut off. Generally, the contacts of circuit breakers and relays The arc extinguishing is based on this principle. DC current has no zero-crossing point. It can only rely on increasing the arc resistance during the process of arc elongation, limiting the current, and extinguishing the arc. However, the distance that ordinary AC electric shocks can pull is limited, unless there are measures such as magnetic blowing. Otherwise, the ability to break DC is very limited, so the ability of AC contacts to break DC will be very small.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !