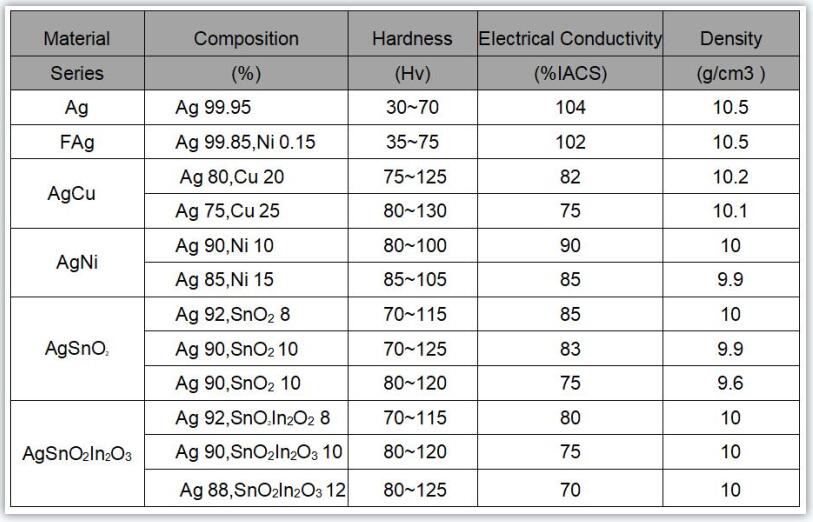

1-Layer Material:Ag,AgNi,AgSnO2,AgSnO2ln2O3,AgCdO,AgZnO

2-Base Material:Copper

3-Surface Plating:No plated or as require Silver-plated,Gold-plated,Nickel-plated.

4-OEM/ODM:Accepted,need your drawing

5-Free Samples:10-50pcs is allowed

6-Lead Time:Samples 3-5days,Orders 7-10days

7-Production Capacity:300,000,000 pcs/month

8-Packing:Inner plastic bag/box,Outer carton/pallet

9-Payment Item:T/T,L/C by USD/EUR/RMB

10-Quality Standard:ISO9000,IATF16949,RoHS,REACH

11-Application:Relay,Contactor,Switch,Thermostat,Breaker,other High/Low-voltage electrical appliances

XIAMEN APOLLO manufactures Solid Silver Contacts,Composite Bimetal Contacts and Trimetal Contact Rivets for Relays and all kinds of switching devices for the measurement and control of electricity.On over 300 different rivet cold heading manufacturing machines, including internally developed cold and hot bonding machines, we produce about 3 billion Contact Rivets annually for customers around the world. In addition we supply XIAMEN APOLLO's Internal Stamped Parts production with Electrical Silver Contact Rivets.

There are many factors that affect Electrical Contacts resistance. In order to facilitate a systematic grasp, the main factors will be reviewed here.

1. Electrical Contact Rivet materials (including surface coating materials)

In order to prevent cold welding of the contacts, it is necessary to use Silver Coated Electrical Contacts materials with higher hardness, such as rhodium/gold-cobalt alloys. However, in order to obtain low contact resistance and improve contact performance, the hardness of the material should not be too high. Therefore, it should be selected according to actual needs. The chemical stability of the material of Silver Electronic Contact should be good, the anti-pollution, corrosion resistance, and oxidation resistance should be strong, the conductivity of the material should be good, and the resistivity should be low to meet the requirements of small and stable contact resistance.

2. Silver Contact Points pollution

Pollutants include dust, moisture, fibers, organic gas liquids, etc., come from the surrounding environment, processing technology, and the structural materials of the relay itself (such as insulating materials). Pollution is an important factor affecting Silver Electrical Contacts resistance, which will produce larger membrane resistance. And chemical corrosion, increase contact resistance and reduce life span. Therefore, clean production and ultra-clean production are required to reduce pollution. The use of full sealing technology or contact system, electromagnetic system separate sealing technology is one of the anti-pollution measures.

3. Electrical Contacts temperature

The increase in the surface temperature of the Oxidized Electrical Contact (including the increase in the ambient temperature and the temperature of the State or Moving Silver Contact itself) will cause the surface condition and Silver Alloy Electrical Contact Rivets area to change. When the Electrical Silver Contacts pressure is constant, the temperature rise will increase the resistance, so the Silver Contact Rivet resistance will increase. When the temperature rises to a certain level, the Point Contact will be softened, the Contact Point area will increase, and the Silver Contact Rivet resistance will decrease. In addition, the increase in temperature will aggravate the oxidation and chemical corrosion of the Cold Headed Bimetal Contacts metal, which is not conducive to the stability and reliability of the work. Measures to improve heat dissipation conditions include: filling high-pressure gas or blackening the cover.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !