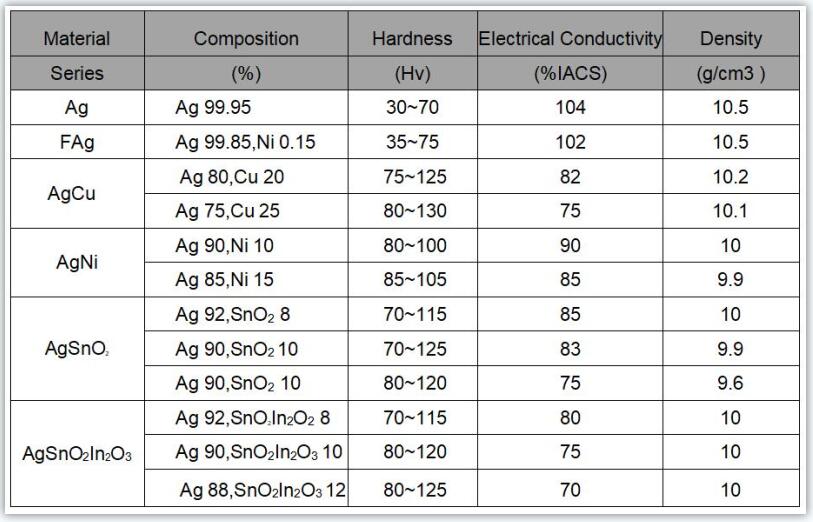

1-Layer Material:Ag,AgNi,AgSnO2,AgSnO2ln2O3,AgCdO,AgZnO,etc

2-Base Material:Copper

3-Rivet Style:Copper Solid Contact,Bimetal Contact,Trimetal Contact

4-Surface Plating:Usually Silver-plated 1-20μm,Gold-plated and Nickel-plated 1-3μm,all as your requires

5-Application: Relays,Circuit Breakers,Switches,Contactor etc.

Why are some Electrical Contacts Gold Plated?

Gold is really expensive. Why then would anyone bother to plate silver contacts with gold? Does it have some unique electrical characteristics that make it useful? Electrical Contacts Gold Plated provide reliable switching when the wetting current is low, because there is no oxide to breach for electrical contact to occur. Ex: a pushbutton switch used to signal a microcontroller digital input has a pullup resistor sized to flow 50 uA when the switch is closed. A switch without gold plating might not be reliable.

Electrical Contacts Gold Plated have several really unique properties that allow for their frequent use:

1-No corrosion at all, produces no patina;

2-Gold Plated Contacts can be touched with bare hands;

3-Reliable in humid environments (household, automotive, marine);

4-Gold is the least likely metal to oxidize. From this table, it can be shown that Gold's electro-potential value is -1.1, meaning it should not oxidize at all, even in water.this is the primary reason that some electrical contacts are gold plated;

5-Gold is an extremely conductive material, one of the best known;

6-Gold Plating Copper Rivet is very malleable, it is very easy to get a thin sheet of it;

Gold Plated Contacts Coating thickness test methods

Coating thickness test detects the thickness of metal and oxide coatings on the surface of the material. The detection methods are

1-Metallographic method

2-Coulometric method

3-X-ray method.

1-Silver Contacts Gold Plated Metallographic method:

A metallurgical microscope is used to examine the cross section to measure the local thickness of the metal covering layer and oxide film layer. Generally, the thickness detection needs to be greater than 1um to ensure that the measurement result is within the error range; the greater the thickness, the smaller the error.

2-Silver Contacts Gold Plated Coulometric method:

It is suitable for measuring the thickness of single-layer and multi-layer metal coatings by anodic dissolution coulometric method, including measuring the thickness of multi-layer systems, such as Cu/Ni/Cr and alloy coatings and alloyed diffusion layers. It can not only measure the thickness of the covering layer of flat samples, but also measure the thickness of the covering layer of cylindrical and wire rods. It is especially suitable for measuring the metal of multilayer nickel plating and its potential difference. The types of coatings measured are Au, Ag, Zn, Cu, Ni, dNi, Cr.

3-Silver Contacts Gold Plated X-ray method:

It is suitable for measuring the thickness of the metal covering layer that needs to be analyzed in the electroplating and electronic circuit board industries. Including: gold (Au), silver (Ag), tin (Sn), copper (Cu), nickel (Ni), chromium (Cr) and other metal element thickness.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !