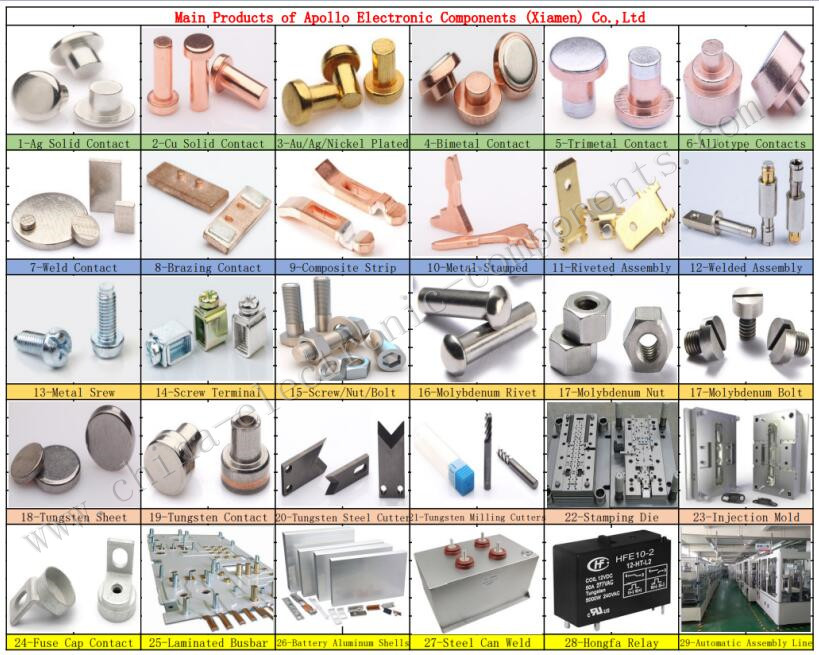

1-Layer Material:Ag,AgNi,AgSnO2,AgSnO2ln2O3,AgCdO,AgZnO,etc

2-Base Material:Copper

3-Rivet Style:Copper Solid Contact,Bimetal Contact,Trimetal Contact

4-Surface Plating:Usually Silver-plated 1-20μm,Gold-plated and Nickel-plated 1-3μm,all as your requires

5-Application: Relays,Circuit Breakers,Switches,Contactor etc.

Electrical Contacts Gold Plated have several really unique properties that allow for their frequent use:

1-No corrosion at all, produces no patina;

2-Gold Plated Contacts can be touched with bare hands;

3-Reliable in humid environments (household, automotive, marine);

4-Gold is the least likely metal to oxidize. From this table, it can be shown that Gold's electro-potential value is -1.1, meaning it should not oxidize at all, even in water.this is the primary reason that some electrical contacts are gold plated;

5-Gold is an extremely conductive material, one of the best known;

6-Gold Plating Copper Rivet is very malleable, it is very easy to get a thin sheet of it;

The Advantages of Using Gold-Plated Electrical Contacts:

1-Gold is an expensive material that increases the cost of the manufacturing process, so why it is so frequently used to plate gold electrical contacts? Gold contains numerous unique properties that can enhance the finish and improve the quality of the workpiece Gold Plated Bimetal Contacts. Many manufacturers discover that the additional cost of gold plating is offset by the benefits derived, resulting in a solid long-term return on investment.

2-Exceptional corrosion protection: Gold is among the metals that are least susceptible to oxidation. This occurs when iron — or an alloy containing iron — combines with oxygen and moisture and ultimately produces corrosion. Therefore, Gold-plated Rivets Contacts can offer a viable solution for applications where rust prevention is essential.

3-Increased electrical conductivity: The formation of surface oxides can also inhibit the Gold Plating Contacts ability to conduct electricity. Gold’s anti-oxidation properties prevent this from occurring. Gold Coating Electrical Contacts also produce a smooth finish that enables a solid connection with the mated surface.

4-Ease of coating application: When electroplating any metal onto Electrical Silver Contact, it is imperative that only a very thin coating is applied. Thick gold coatings will negatively impact silver contact performance. Gold is one of the most malleable metals, making it easy to apply a very thin coating onto the surface. The fact of Gold Plated Contacts that only a thin layer of gold is required also helps to minimize the cost.

5-Enhanced durability: Gold provides excellent resistance against normal wear and tear, which can lengthen the Au Plated Contacts lifespan.

6-Excellent heat protection: For Electrical Silver Contacts products routinely exposed to elevated temperatures, gold provides superior protection against damage causes by excessive heat.

7-No fretting degradation: Gold is not susceptible to fretting, which is the gradual wearing away of the Electrical Contact Point surface due to rubbing or friction.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !