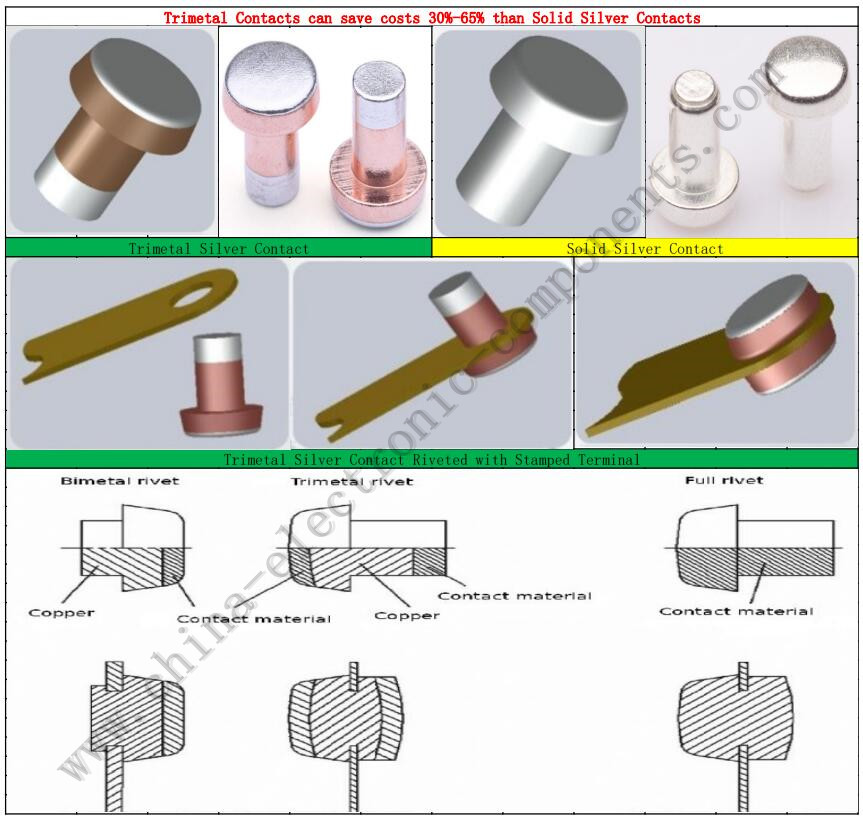

1-Trimetal Contacts can save costs 30%-65% than Solid Silver Contacts;

2-Very reliable mechanical strength for both sides composite materials,like Solid Contacts;

3-The silver layers on the head and foot are accurately distributed to ensure the contacts gap after riveted with stamped terminal;

4-Surface anti-oxidation protective film, can resist oxidation for a long time;

5-High dimensional accuracy ±0.01-0.02mm;

6-Strong corrosion resistance;

7-Good electrical conductivity.

Nowadays, the commonly used contact elements on the market are small in size, but have very strict performance requirements. Most of the existing contact elements are made of pure silver and pure copper materials directly by manual riveting and automatic riveting, with low strength, low hardness, low welding resistance and arc burning resistance, and the materials involve a variety of precious metals Materials, most of the existing composite contact manufacturing equipment have complex structures and poor molding efficiency, which not only wastes raw materials, but also the molded composite contacts have low strength and hardness, unstable connection, high cost, and small application range,so the Trimetal Silver Contacts is the best choice to reduce costs and increase efficiency.

The Trimetal Rivet-type Contacts include a pure copper matrix, a silver compound composite layer and a connecting composite layer. The pure copper matrix is composed of a truncated cone-shaped head and a cylindrical foot, and the cone-shaped head and the cylindrical foot are integrally arranged, A first groove is provided on the side of the head facing away from the foot, and a silver compound composite layer is provided on the first groove. The silver compound composite layer is embedded with the first groove, and the foot the side facing away from the head is provided with a second groove, the second groove is provided with a connecting composite layer, and the connecting composite layer is embedded with the second groove. The Trimetal Rivets of the utility model has good electrical conductivity, and the silver compound composite layer on the head is not easily deformed and will not fall off from the pure copper substrate.

The Tri Metal Contact Rivets are contacts composed of two or three materials. Generally, the head is covered with silver (silver alloy), the base is copper, and the feet are also covered with a layer of silver (silver alloy). , This process is slowly becoming popular internationally and is a good cost-saving method; the spot welding type Three Compound Contacts are also a contact composed of two or three materials. The common one is a layer of silver (silver alloy ), the middle layer is copper, and the bottom layer is iron (or iron plated with nickel or Monel alloy).

What conditions may cause the failure of Electrical Silver Contacts?

1. Silver contacts are vulcanized. Since silver is easily chemically reacted to sulfur, sulfides are produced. Assuming there are rubber bands, sulphur-containing wrinkled paper, sulphur tape, rubber pads, rubber tires, sulphur gas, etc., this may cause the silver contacts to turn black. As the ambient temperature increases, the vulcanization rate can be increased.

2. Silver Contact Rivets are polluted by dust. Air dust will adhere to the outside of the silver contacts.

3. Acid corrosion of silver contacts. The Silver Contact Point treated with nitric acid leaching and electroplating techniques turn away from the outer surface of the silver alloy, and the metal is exposed to the air to form metal oxides. Part of the battery phenomenon: also called a micro battery. Many fine short-circuit galvanic cells consist of thin metal films and are covered with electrolyte solutions.

4. During the use of Cold Headed Electrical Contacts, some metals are more active and prone to electrochemical corrosion. If carbon dioxide and water vapor in the air are absorbed by the surface and become an electrolyte solution, it will cause mechanical corrosion. It will affect the normal use of the equipment, so be careful.

5. Other pollution. For example, automobile exhaust, dust, sweat, oil stains, etc., if exposed to carbon dioxide at high temperatures during the use of electrical switches, the Silver Electrical Contact may fail.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !