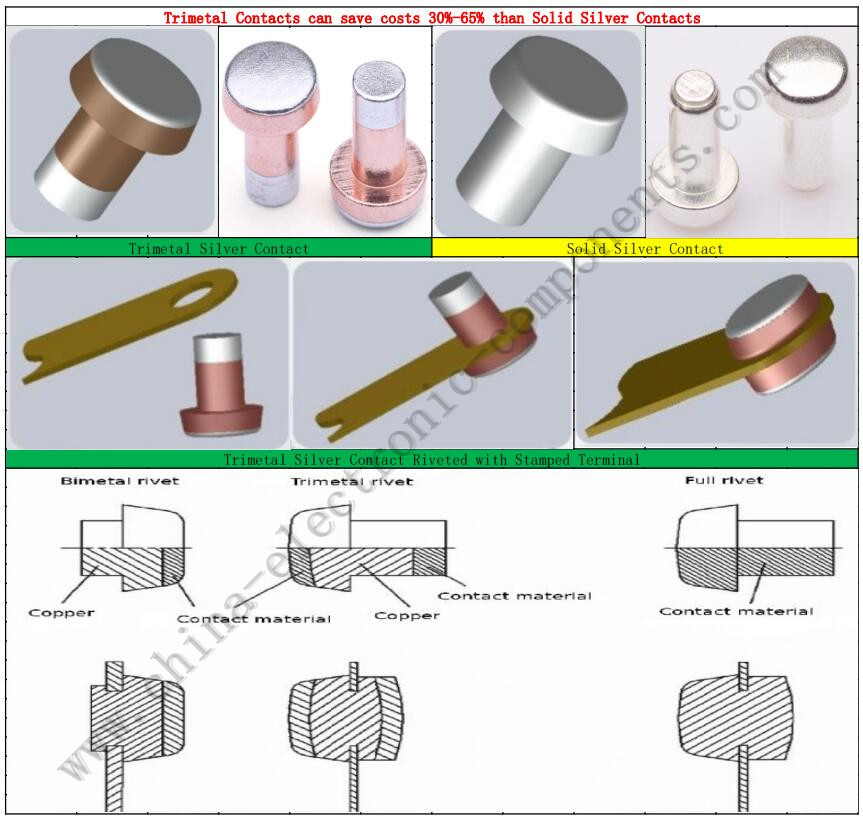

Our products Trimetal Electric Contacts Features:

1-Trimetal Contacts can save costs 30%-65% than Solid Silver Contacts;

2-Very reliable mechanical strength for both sides composite materials,like Solid Contacts;

3-The silver layers on the head and foot are accurately distributed to ensure the contacts gap after riveted with stamped terminal;

4-Surface anti-oxidation protective film, can resist oxidation for a long time;

5-High dimensional accuracy ±0.01-0.02mm;

6-Strong corrosion resistance;

7-Good electrical conductivity.

The Trimetal Rivet-type Contacts include a pure copper matrix, a silver compound composite layer and a connecting composite layer. The pure copper matrix is composed of a truncated cone-shaped head and a cylindrical foot, and the cone-shaped head and the cylindrical foot are integrally arranged, A first groove is provided on the side of the head facing away from the foot, and a silver compound composite layer is provided on the first groove. The silver compound composite layer is embedded with the first groove, and the foot the side facing away from the head is provided with a second groove, the second groove is provided with a connecting composite layer, and the connecting composite layer is embedded with the second groove. The Trimetal Rivets of the utility model has good electrical conductivity, and the silver compound composite layer on the head is not easily deformed and will not fall off from the pure copper substrate.

Ag/Cu/Ag Tri-metal Contact Rivets are manufactured either by bonding of multiple wire segments or by cutting and forming from a suitable tri-metal strip. When using the latter method it is also possible to use different Tri-metal Rivet Contacts materials for the contact layers if different load conditions have to be controlled.Trimetal Contact Rivets are more advanced compared to Bi-Metal Contacts. To reduce the production cost and to fight against the threat for increasing silver prices, Electrical Trimetal Rivet Contacts are solving the purpose. We have the capability to manufacture Trimetal Contact Rivets with silver alloy layer of any composition bonded with ETP Copper on both sides.

The new Ag/Cu/Ag Trimetal Contacts include a matrix and a composite layer. The matrix is composed of a head and a foot. The head and the foot are both cylindrical, and the diameter of the head is larger than the diameter of the foot. The composite layer includes a head composite layer and a foot composite layer, the head composite layer is composited on the upper surface of the head, and the foot composite layer is composited with the lower surface of the foot; the matrix is made of pure copper material , The composite silver layer is made of silver alloy material, and the silver alloy is composed of fine-grained silver; the beneficial effects of the utility model: the utility model relates to providing Trimetal Electrical Rivets using pure copper and silver alloy, The composite molding of pure copper and fine-grained silver materials is used, with low production cost, high material strength, high welding resistance and arc burn resistance, high electrical conductivity, and low contact resistance. Three Compound Rivets are suitable for low-voltage electrical appliances with operating currents below 10A. The Electric Double Metal Contact Rivet that can replace pure silver materials are applied to many occasions.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !