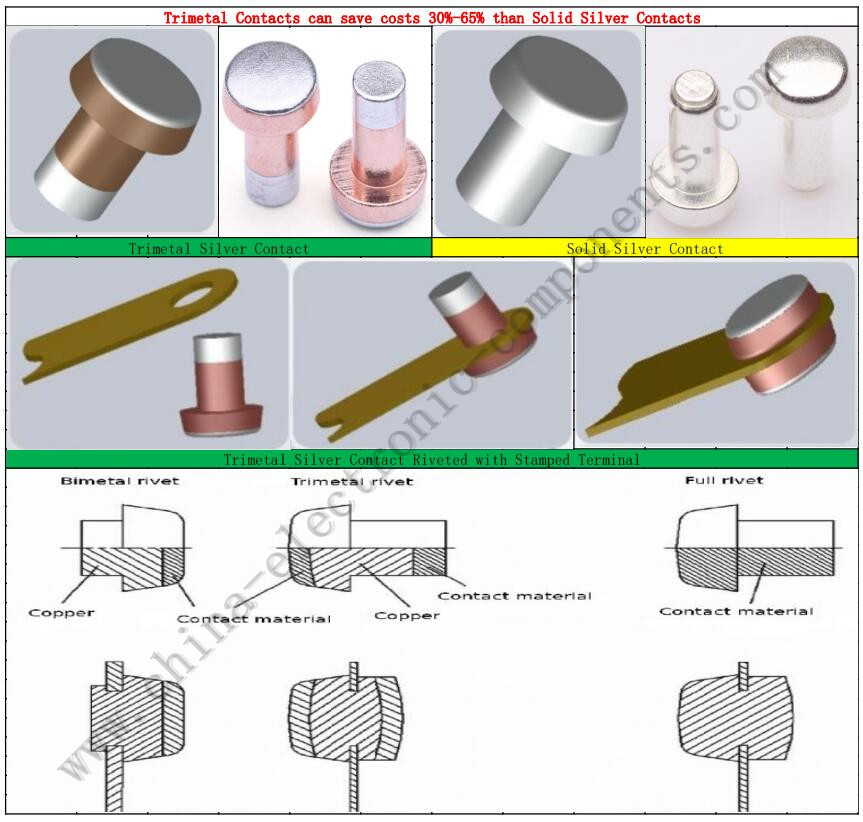

Our products Trimetal Rivet-type Contacts Features:

1-Trimetal Contacts can save costs 30%-65% than Solid Silver Contacts;

2-Very reliable mechanical strength for both sides composite materials,like Solid Contacts;

3-The silver layers on the head and foot are accurately distributed to ensure the contacts gap after riveted with stamped terminal;

4-Surface anti-oxidation protective film, can resist oxidation for a long time;

5-High dimensional accuracy ±0.01-0.02mm;

6-Strong corrosion resistance;

7-Good electrical conductivity.

The Tri Metal Contact Rivets are contacts composed of two or three materials. Generally, the head is covered with silver (silver alloy), the base is copper, and the feet are also covered with a layer of silver (silver alloy). , This process is slowly becoming popular internationally and is a good cost-saving method; the spot welding type Three Compound Contacts are also a contact composed of two or three materials. The common one is a layer of silver (silver alloy ), the middle layer is copper, and the bottom layer is iron (or iron plated with nickel or Monel alloy).

In order to overcome the shortcomings in the prior art, the purpose of the present invention is to provide Tri Metal Contacts and a manufacturing device for the triple composite contact. The triple composite contact has a simple structure, good strength, hardness, welding resistance and arc burn resistance. The device for manufacturing the Trimetal Rivet Contacts can directly cut the raw material and can be directly cold-headed, which is convenient to use and low in cost. High efficiency, effectively ensuring the strength and hardness of the contacts, and a wide range of applications.

Tri-metal Rivet Contacts are normally used as double sides contacts,mainly used in Relays, Micro Switches,Button Switches and Contactors,etc.Trimetal Material have Ag/Cu/Ag,AgNi/Cu/AgNi,AgCdO/Cu/AgCdO,AgZnO/Cu/AgZnO, AgSnO2/Cu/AgSnO2,AgSnO2In2O3/Cu/AgSnO2In2O3 and so on.Available with us is a range of Contact Rivets. Trimetal Electrical Contacts are manufactured with wire by cold heading process. This helps in making the shank soft for easy riveting and the head is work-hardened. The length of the shank can be varied but the diameter of Trimetal Contact Rivets is needed to be in right proportion to the size of head. This enables us to avoid wrinkles during cold forging operation. These economically priced Composite Contact Rivets can be manufactured in various dimensions. The limit to the dimension of Multi-layer Silver Contacts is due to the requisite ratio between head diameter to head thickness.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !