Why Choose Our products Cold Headed Electrical Contacts:

1-Exworks factory price

2-Reliable and safe depend on group companies

3-Professional and focus for 20+ years

4-Technical services by 24h and 365days

We are engaged in manufacturing an engineered range of Electric Rivets and Electrical Contacts that include Solid Electrical Contact Rivets, Bimetal Electrical Contact, Bi-metal & Solid Silver Tips, Tri-metal Electrical Contact, Copper & Brass Rivets,Brass Contact Bracket,Welding Contact Tip,Riveting Electronic Component,etc.Silver Electrical contact mainly usedsmall and medium-sized current contactor, starter, temperature controller, switches, relay etc. undercurrent contact devices, micro switches and precision instruments.

Operation steps of Electrical Silver Contacts factory inspection:

1. First of all, when you get a batch of Bimetal Silver Contacts, you should pay attention to whether the product packaging meets the standard requirements, whether the Bimetallic Silver Contacts identification matche the actual product, the weight and quantity of the product are accurate, and whether the vacuum is qualified. Secondly, check whether there are silver chips, copper chips and other foreign objects in the packaging bag.

2. Before inspection, check the Composite Contacts with a magnet, and sample 2~3 plates in each batch. If abnormalities are found, report to the supervisor in time for handling.

3. Appearance inspection: the surface of the Cold Headed Bimetal Contacts are generally visually inspected (use a 40x microscope if necessary). The surface of the Electrical Silver Contacts should be free of oil stains, oxidative discoloration, erythema, macula, and fog. The surface of the Silver Cadmium Contacts should be free of cracks and pits. No obvious indentation. There should be no visible cracks on the joint edges of the Composite Contacts, and no obvious burrs, flashes, missing edges and other abnormal phenomena on the edges of the Silver Contact Rivet.

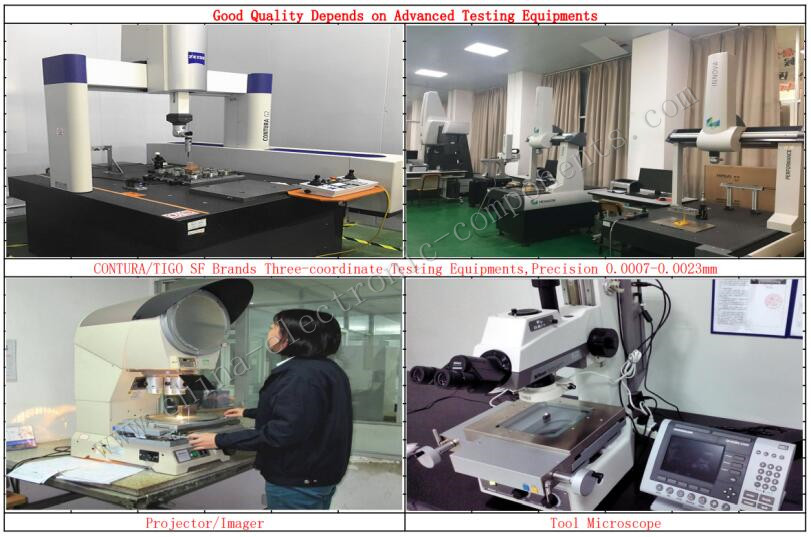

4. Product size inspection: each batch needs to be sampled, and the Point Contacts φD, φd, L, T are measured with a 0-25mm micrometer. The silver layer S, the contact spherical radius SR and the demolding angle θ are measured with a projector, and their values must meet the requirements of the Contact Points drawings. (When measuring the silver layer S, throw away the contact along the meridian surface and polish it on metallographic sandpaper. The thickness of the composite layer of the Bimetal Silver Contact should be greater than or equal to the size requirement of the drawing within the range of 1/4D. If the customer has special requirements required to implement).

5. Inspection of product bonding strength: each batch Electrical Contact Point needs to take 5-10 samples, use flat-nose pliers or small vise and other special clamps to flatten the Silver Alloy Electrical Contact Rivets head to 1/2 of the original φD, check the flattening and touch Whether there is a crack at the point joint, the depth of the crack shall not be greater than 1/6 of the maximum length of the clamp.

6. Resistance measurement: sample 8 grains in each batch Electrical Contact Silver Point to check the resistance, put the Cold Headed Electrical Contacts on the test base of the CRM-2A contact resistance tester and wait for the contact pins to vertically touch the surface of the Bimetalic Rivets, and the indicator light changes from red to red Green, the contact pressure of the contact is 100 mN±5 mN, the test current is 10mA±0.5 mA, and the reading is within 3s~5s after the test current is applied. Take the center point of the Silver Electrical Contact working surface as the detection point, and only measure the Electrical Contact Rivet resistance of one point. The contact resistance of the contacts should meet the requirements.

7. The surface roughness of the Electrical Contacts are checked with a roughness detector, or the sample confirmed by both the supplier and the buyer is sealed as a reference for the inspection.

8. The coaxiality of the Electronic Contacts are measured with a projector or a special measuring tool, and its value should meet the requirements of the drawing.

9. Fill in the above-mentioned test data on the Electrical Fixed Contacts quality inspection report and the factory Silver Coated Electrical Contacts quality status record form. The handwriting is required to be correct, clear, unconventional, unaltered, and fill in true and timely.

10. Other requirements:

① The work site is tidy, clean and free of debris.

② The product classification is clear, clearly marked, and neatly placed.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !