Why Choose Our products Electrical Contacts:

1-Exworks factory price

2-Reliable and safe depend on group companies

3-Professional and focus for 20+ years

4-Technical services by 24h and 365days

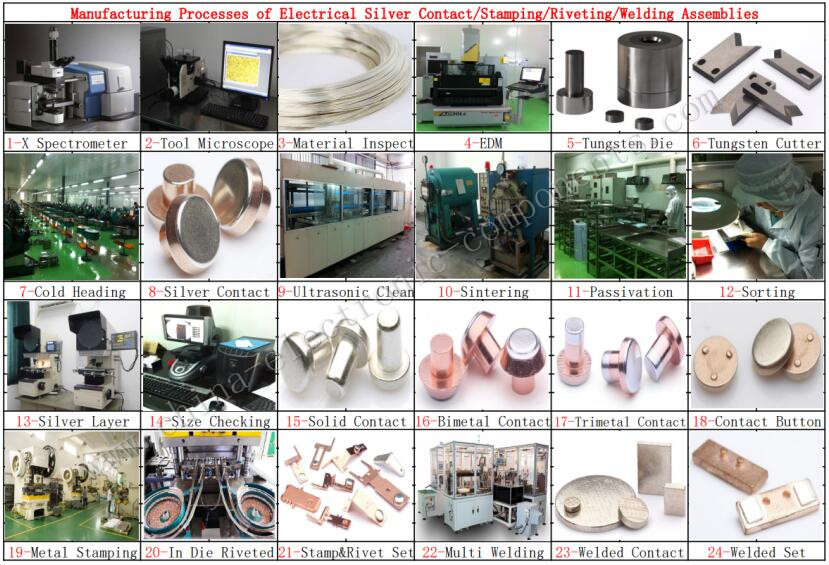

The process of In-die Riveting Silver Contacts

The process steps of the riveting of the silver contact riveting terminal in the mold: Contact Point progressive die punching brake reed → moving reed pickling → riveting Electrical Silver Contacts → bending of the Moving Spring Contact Assembly. Due to the large production volume of this product, in order to improve Production efficiency, stable product quality, and reduce production costs. The new process route formulated is: progressive die with material to produce moving reed strip → strip cleaning → strip riveting Electrical Silver Contacts and forming.

Silver contact riveting terminal riveting is a common mechanical connection method, which is more commonly used in metal secondary processing such as stamping, and spin riveting is generally used to connect electronic conductive Electrical Silver Contacts and reeds. Traditional spin riveting is generally completed by the operator after manual assembly on the spin riveting machine. This process not only has low production efficiency, but also has unstable spin riveting quality.

The in-mold riveting Point Contact method used in stamping realizes that the reed is formed in the multi-station progressive die while using automatic control technology to realize the automatic feeding and precise positioning of the conductive Silver Contact Rivet from the mold and the riveting forming, which can not only improve Production efficiency and stable riveting quality.

We are engaged in manufacturing an engineered range of Electric Rivets and Electrical Contacts that include Solid Electrical Contact Rivets, Bimetal Electrical Contact, Bi-metal & Solid Silver Tips, Tri-metal Electrical Contact, Copper & Brass Rivets,Brass Contact Bracket,Welding Contact Tip,Riveting Electronic Component,etc.Silver Electrical contact mainly usedsmall and medium-sized current contactor, starter, temperature controller, switches, relay etc. undercurrent contact devices, micro switches and precision instruments.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !