1-Exworks factory price

2-Reliable and safe depend on group companies

3-Professional and focus for 20+ years

4-Technical services by 24h and 365days

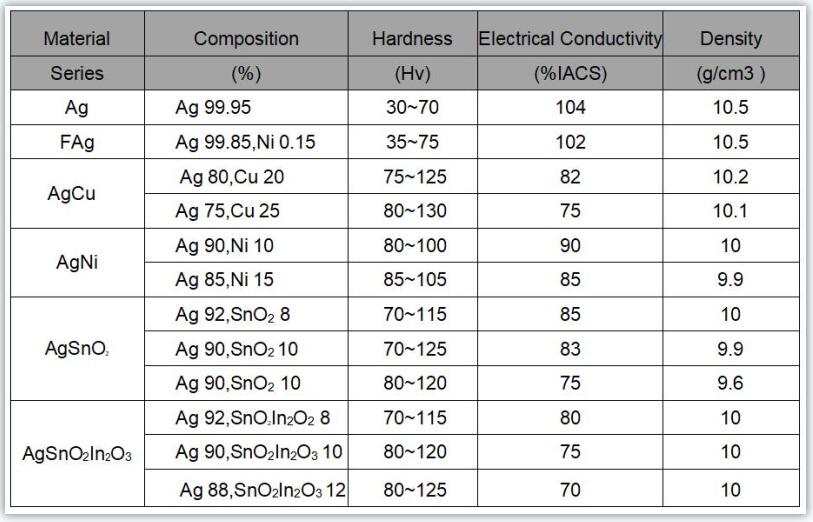

With increasing silver prices, lower silver content of Bimetal Contact allows choice of larger contact than with Solid Silver Contact to get better current rating.Silver Contact layer is normally half the thickness of the head. To suit specific requirements, variation on this ratio is possible within practical limits.Electrical Contacts silver layer can be made of silver alloys like PAg,AgNi,AgSnO2,AgSnO2ln2O3,AgCdO,AgZnO etc,variation of this silver Ag alloys can also be offered.Bimetal Contacts can be Silver-plated,Gold-plated,Nickel-plated if required.

We are engaged in manufacturing an engineered range of Electric Rivets and Electrical Contacts that include Solid Electrical Contact Rivets, Bimetal Electrical Contact, Bi-metal & Solid Silver Tips, Tri-metal Electrical Contact, Copper & Brass Rivets,Brass Contact Bracket,Welding Contact Tip,Riveting Electronic Component,etc.Silver Electrical contact mainly usedsmall and medium-sized current contactor, starter, temperature controller, switches, relay etc. undercurrent contact devices, micro switches and precision instruments.

How to prevent silver contacts from oxidizing during use

1. The silver contact riveting workshop should be dust-free to prevent dust and other foreign objects from adhering to the contact surface during processing;

2. Please pay attention to the surrounding environment of the processing site, and separate the organic plastic material from the contact element to prevent organic matter from adhering to the Silver Alloy Electrical Contacts surface and causing poor contact;

3. The personnel performing the riveting process must perform the operation before operating the finger cots. Do not touch the surface of the silver layer of the Silver Electronic Contact as much as possible to avoid oxidation (blackening);

4. Suitable for Electrical Silver Contact Point processing workshop, the ambient temperature is 22~24°C, the relative humidity is 40~55%RH;

5. In order to avoid vulcanization (yellowing) of Silver Contact Points, the opened silver contacts will be used up within 12 hours. If it is not used up, please reseal the remaining Electrical Contacts (preferably vacuum packed).

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !