Our products Cold Headed Bimetal Contacts Features:

1-The contact resistance is low and stable

2-Good welding resistance and thorough opening and closing

3-Good conductivity

4-Good abrasion resistance,the contact surface not changed

5-Not easy to oxidize for a long time

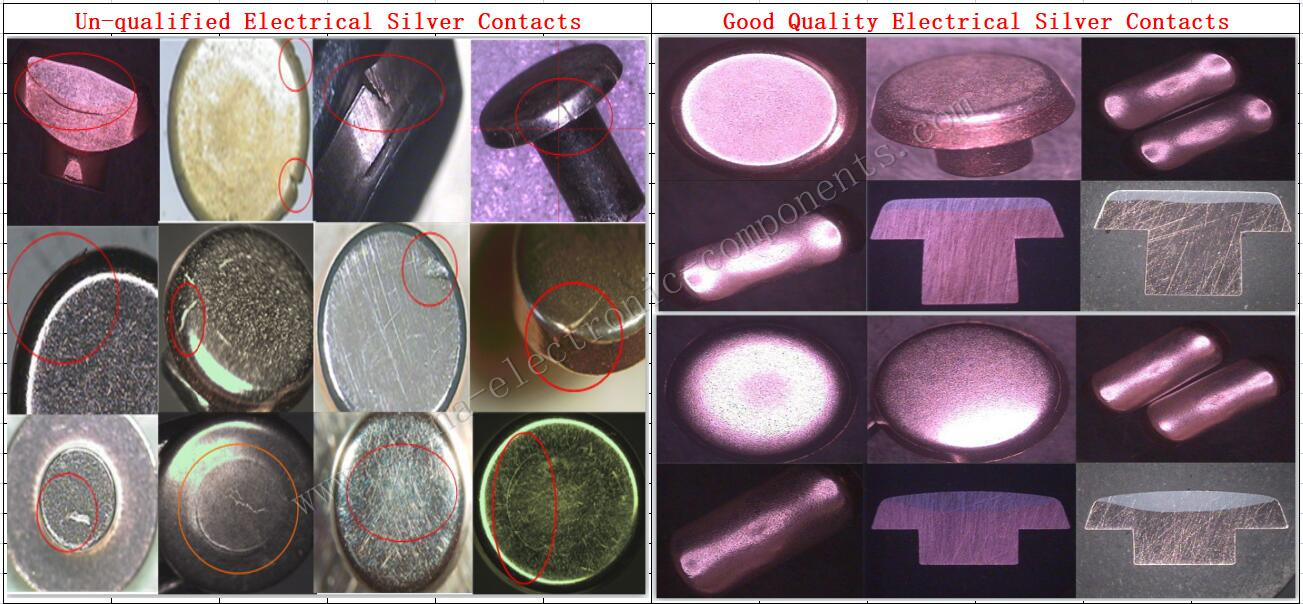

Silver Electrical Contacts refer to the electronic appliances when opening and closing, separation and mutual contact of intersections, because the metal conductor terminals at the instant of the contact prone to moments of fever and spark, prompting them to Silver Contact Point in the process of using multiple frequency, prone to oxidation and electrolysis, so will increasing the thickness of the Bimetal Contact Rivets, or manufactured polymer metal (copper and multiple) with different material, so will called Bimetal Rivet Contact.

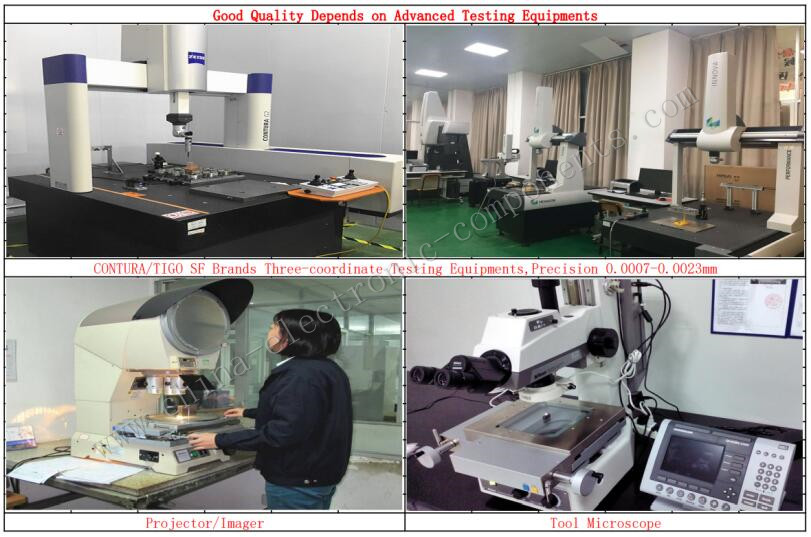

The manufacturing and test equipments of Precision Electrical Contacts which is total amount more 300 sets for making Contact Rivet include Tri-metal rivet machine from Germany, Bi-compoundedrivet machine, Colored Microscope, 3D coordinator Apparatus, Hardness Test Machine, etc. We can develop and manufacture Bimetal Contacts Ag/Cu according to customers'specific requirement, and the output can surpass 3 billion pieces Bimetal Electronic Contacts annually.

we are leader supplier of Bimetallic Contact Rivet in this field in China,and we are factory,have the best price,can supply the Ex-works for our customers.We have been professional in manufacturing Bimetallic Rivet Contact for more than 20 years in China.As well known,the Bimetal Silver Contacts price is changeable according to the silver raw material price in market,it will make buyers confused and difficult to make sure how operate purchasing plans for Bimetallic Silver Contacts . But we have our own Silver Alloy Contact raw material factory,have a lot of silver and copper material in store,so we have strong risk-resisting ability to give our customers the best and Ex-works price.

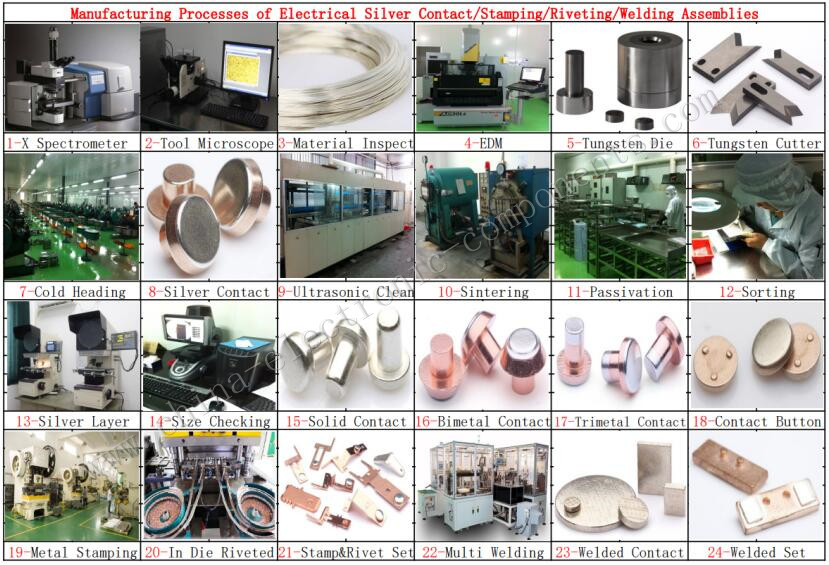

The process of In-die Riveting Silver Contacts

The process steps of the riveting of the silver contact riveting terminal in the mold: Contact Point progressive die punching brake reed → moving reed pickling → riveting Electrical Silver Contacts → bending of the Moving Spring Contact Assembly. Due to the large production volume of this product, in order to improve Production efficiency, stable product quality, and reduce production costs. The new process route formulated is: progressive die with material to produce moving reed strip → strip cleaning → strip riveting Electrical Silver Contacts and forming.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !