1-Products Name:Bimetal Silver Contacts

2-Model No:APOLLO-20210101-08

3-Brand Name:XIAMEN APOLLO

4-Country of Origin:XIAMEN CHINA

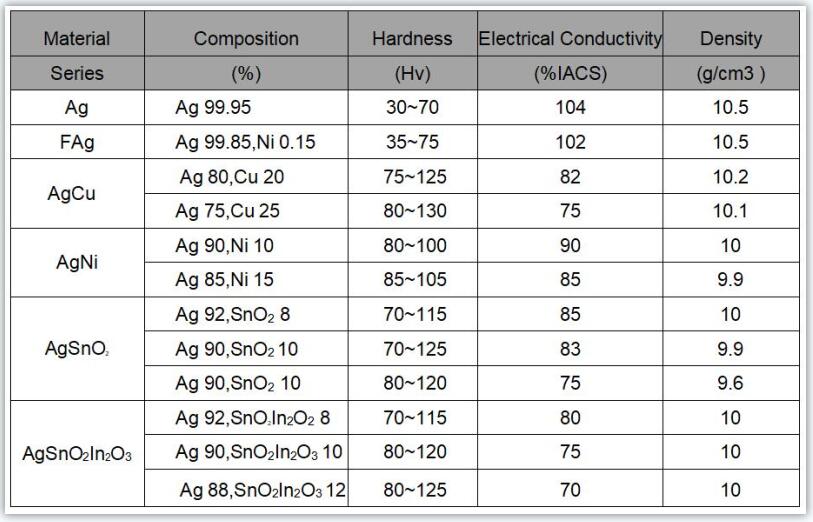

5-Layer Material:Ag,AgNi,AgSnO2,AgSnO2ln2O3,AgCdO,AgZnO

6-Base Material:Copper

7-Surface Plating:No plated or as require Silver-plated,Gold-plated,Nickel-plated.

8-OEM/ODM:Accepted,need your drawing

9-Free Samples:10-50pcs is allowed

10-Lead Time:Samples 3-5days,Orders 7-10days

11-Production Capacity:300,000,000 pcs/month

12-Packing:Inner plastic bag/box,Outer carton/pallet

13-Payment Item:T/T,L/C by USD/EUR/RMB

14-Quality Standard:ISO9000,IATF16949,RoHS,REACH

15-Application:Relay,Contactor,Switch,Thermostat,Breaker,other High/Low-voltage electrical appliances

How to prevent silver contacts from oxidizing during use

1. The silver contact riveting workshop should be dust-free to prevent dust and other foreign objects from adhering to the contact surface during processing;

2. Please pay attention to the surrounding environment of the processing site, and separate the organic plastic material from the contact element to prevent organic matter from adhering to the Silver Alloy Electrical Contacts surface and causing poor contact;

3. The personnel performing the riveting process must perform the operation before operating the finger cots. Do not touch the surface of the silver layer of the Silver Electronic Contact as much as possible to avoid oxidation (blackening);

4. Suitable for Electrical Silver Contact Point processing workshop, the ambient temperature is 22~24°C, the relative humidity is 40~55%RH;

5. In order to avoid vulcanization (yellowing) of Silver Contact Points, the opened silver contacts will be used up within 12 hours. If it is not used up, please reseal the remaining Electrical Contacts (preferably vacuum packed).

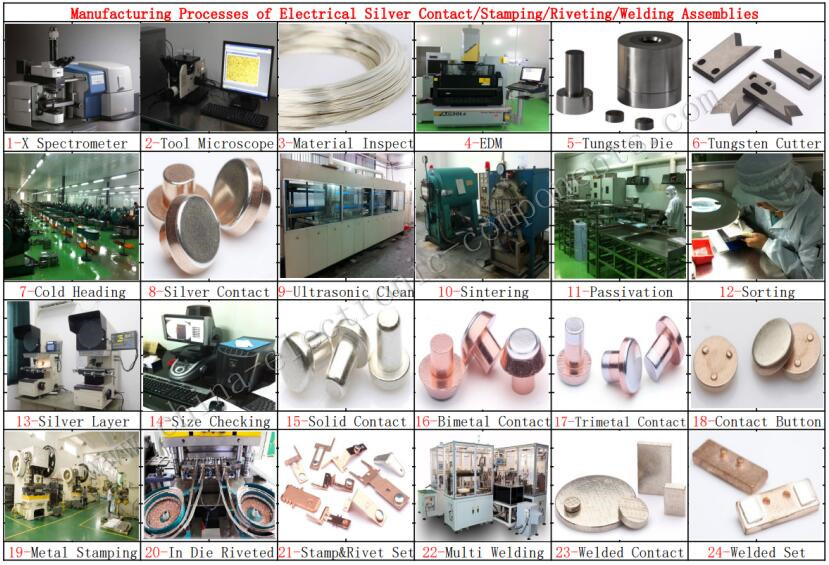

The process of In-die Riveting Silver Contacts

(also take the dynamic spring assembly in the T73 Relay model as an example),

1.The stamping plant produces the armature; 2. The stamping plant directly completes the production of the movable reed assembly by using the Silver Electrical Contacts through the in-die riveting process;

2.Customers only need to provide Oxidized Electrical Contact to the stamping factory; in this whole process, only two toolings are needed: a armature mold, b riveting mold in the movable reed mold (that is, the production of the movable reed and the armature, contact all the riveting is done in this mold). In terms of production efficiency, the speed of this process can be stably controlled between 200 times and 400 times (per minute). If we calculate 300 times per minute, we can achieve the production of 18,000 moving reed components in one hour, 6 hours a day Can reach the output of 100,000 pcs Electrical Contact Stamping Assembly.

More importantly, the riveting process of the client is directly cancelled here, which saves manpower and shortens the process to: it can only be completed in the production workshop of the stamping plant. And the movable reed assembly produced by the in-die riveting Stamping Electrical Contacts process, when assembled into the T73 Relay finished product, the adjustment-free rate can reach 80%-85%, which greatly improves the quality and output of the customer's finished product Electrical Stamping Contact Components. Through the improvement of this technology, we found that the customer's monthly output has increased from 1.5 million finished products to the current monthly output of 5.1 million finished products, which is a full increase of more than three times!

The competitive advantage brought by technological advancement is obvious. In addition to the rising labor costs in the manufacturing industry, more and more relay assembly manufacturers have begun to invest or update automated production lines, and higher requirements are placed on supporting stamping parts suppliers. , In-die Silver Contact Riveting technology has played an active role in this key component.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !