Our products Solid Silver Contact Rivets Features:

1-Good conductivity

2-The contact resistance is low and stable

3-Good welding resistance and thorough opening and closing

4-Good abrasion resistance,the contact surface not changed

5-Not easy to oxidize for a long time

Why Choose Us:

1-Exworks factory price

2-Reliable and safe depend on group companies

3-Professional and focus for 20+ years

4-Technical services by 24h and 365days

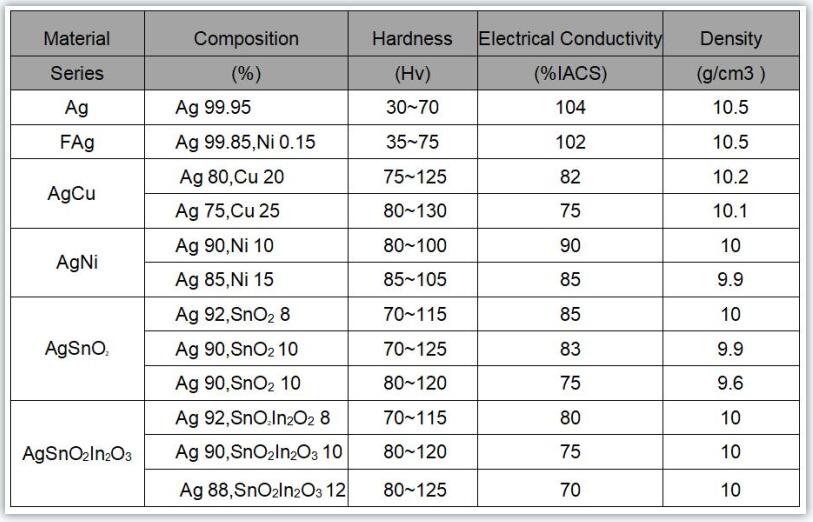

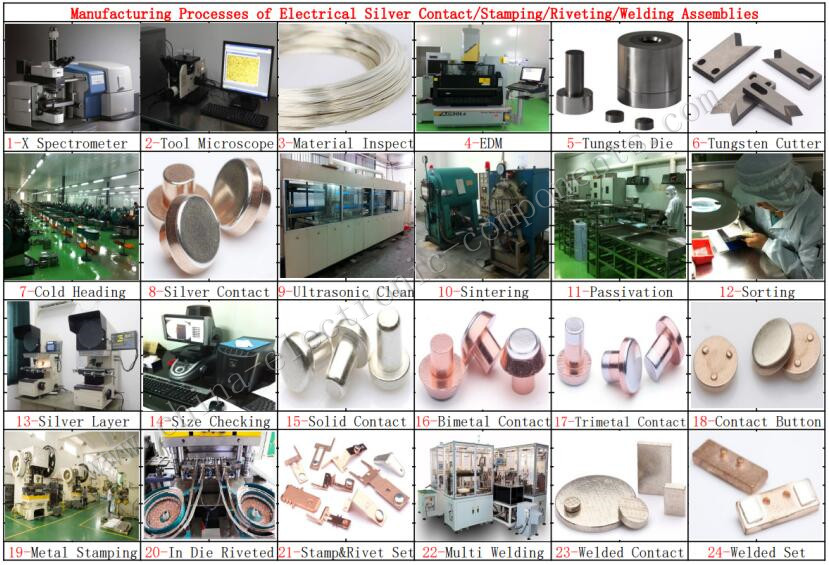

XIAMEN APOLLO manufactures Solid Silver Contacts,Composite Bimetal Contacts and Trimetal Contact Rivets for Relays and all kinds of switching devices for the measurement and control of electricity.On over 300 different rivet cold heading manufacturing machines, including internally developed cold and hot bonding machines, we produce about 3 billion Contact Rivets annually for customers around the world. In addition we supply XIAMEN APOLLO's Internal Stamped Parts production with Electrical Silver Contact Rivets.

And also we produce customized Silver Alloy Contacts to meet customer’s demand. A variety of analytic and inspection equipment are utilized to ensure the quality in the varied steps of Silver Alloy material incoming, processing and final goods. Electric contacts could be used for Relays,Switches, Breakers,Magnetic Contactors and so on.

Silver Contact Rivets advantage:

Pure Silver Electronic Contacts: best conductivity, but easy to stick and easy to solder.

AgCdo (silver-cadmium oxide) Electronic Contacts series: It has good wear resistance, welding resistance and electrical and thermal conductivity, and the contact resistance is small and stable.

AgSno (silver-tin oxide) Electronic Contacts series: high thermal stability, heat resistance, arc erosion resistance and melting resistance, long service life.

AgNi (silver-nickel) Electronic Contacts series: when used for direct current contacts, it has good electrical and thermal conductivity, low contact resistance and stable surface, and electrical loss is small and uniform.

AgSnOlnO (Silver-Indium Tin Oxide) Electronic Contacts series: It has better thermal stability and higher hardness, and has better weldability and durability.

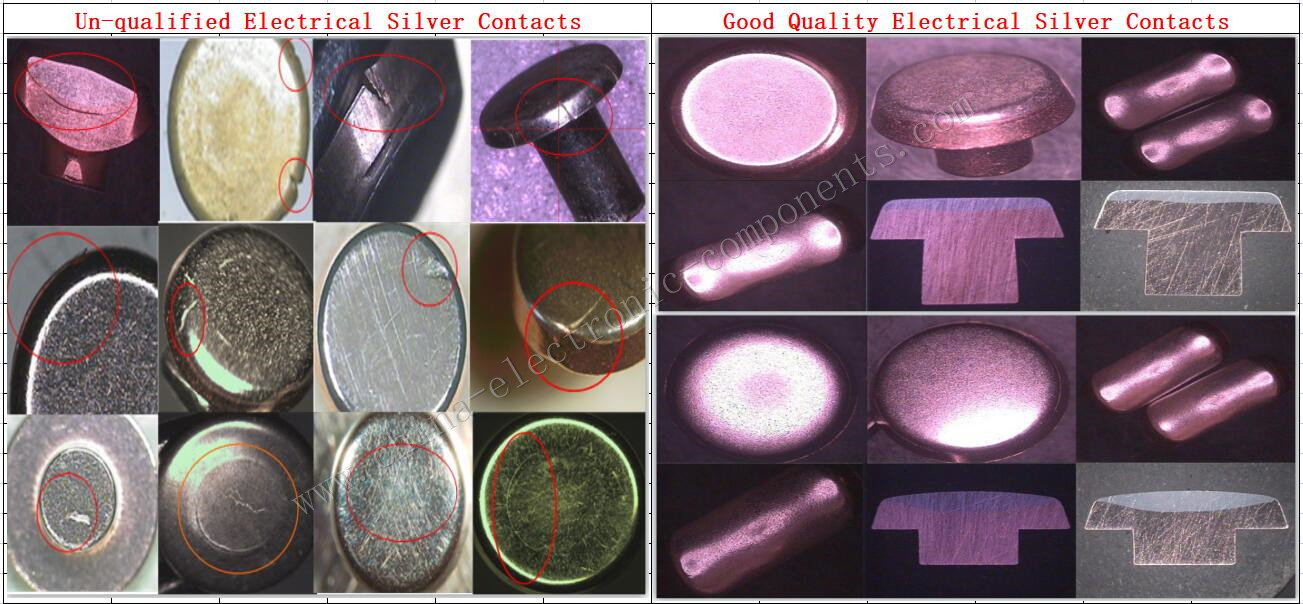

The Solid Silver Contacts refer to the intersection point where the electronic appliances are disconnected and contacted when they are opened and closed. Since the metal conductor terminal is prone to instantaneous heat and sparks at the moment of contact, the Silver Contact Point is prone to oxidation and electrolysis in the multi-frequency process of use, so the Silver Alloy Contacts is increased and thickened, or polymer metal is used Manufacturing (copper and silver are the most common materials), so this Solid Electrical Contacts made of polymer metal, or a point thickened with the same material is called Electrical Silver Contacts.

Electrical Silver Alloy Point Contact are the points in an electrical circuit that connect to a wire to complete the circuit and make it work. They are made out of a variety of different types of silver.

Pure Silver Contacts (also called fine silver) exhibits the highest electrical and thermal conductivity of all metals. They are also resistant against oxidation. Major disadvantages are its low mechanical wear resistance.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !