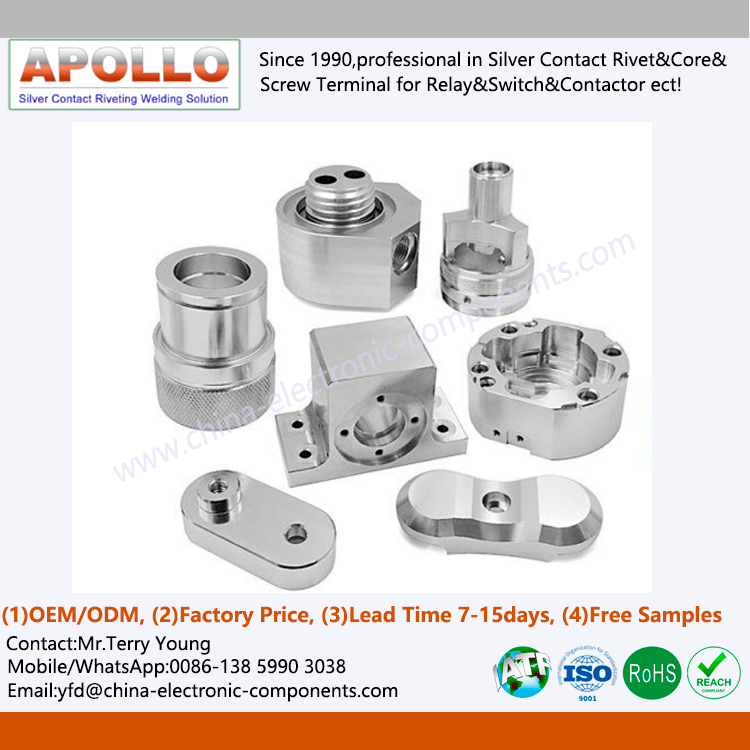

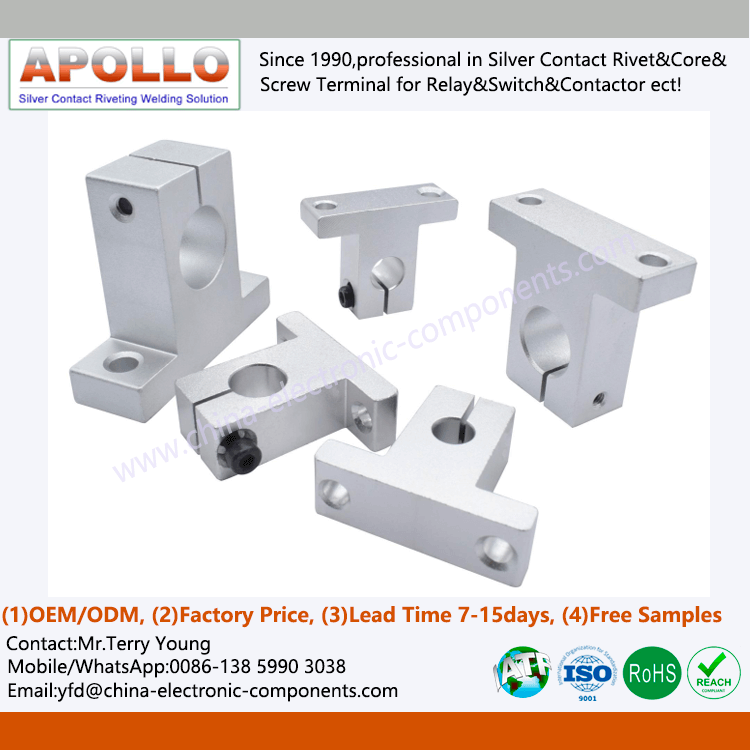

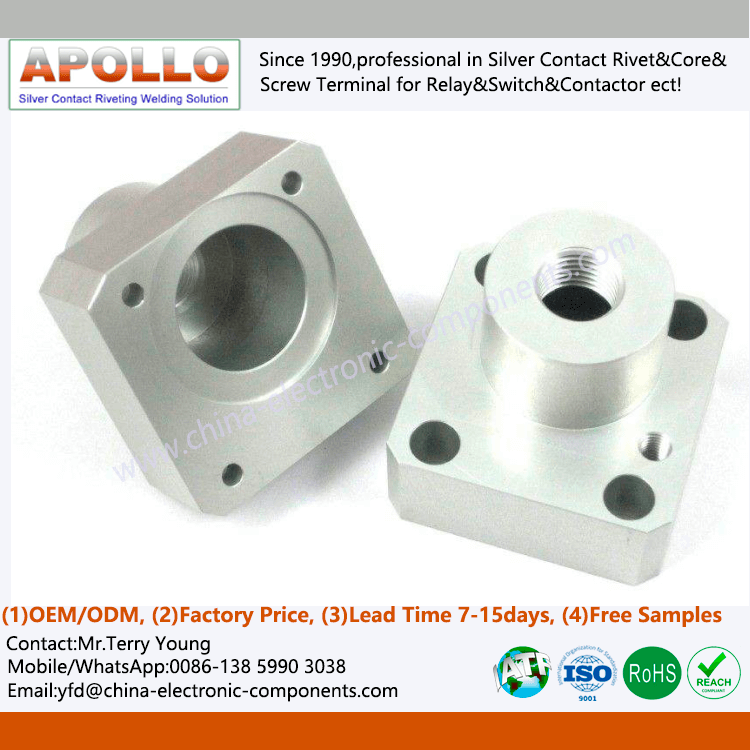

1- Products Name: CNC Milling Aluminum Parts

2- CNC Machining Metal Parts we can make:

Copper, brass, aluminum alloy, stainless steel, magnesium alloy, titanium alloy, zinc alloy and other metal materials.

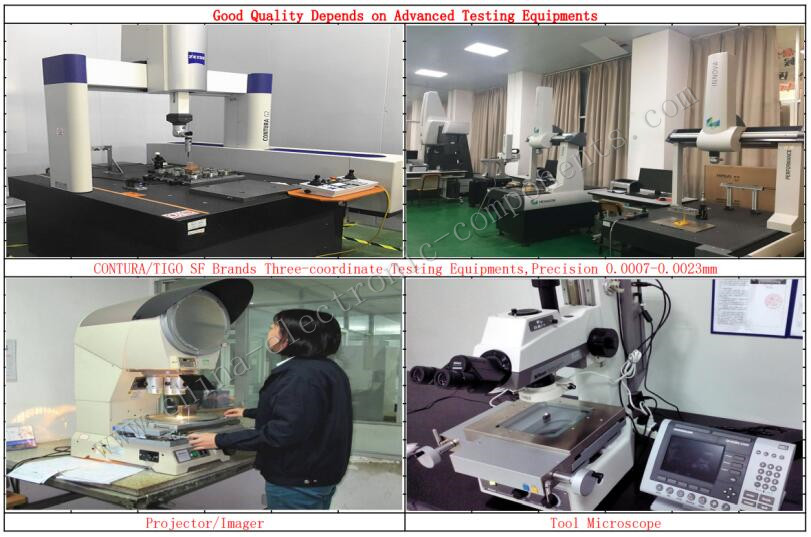

3- Dimensional accuracy of processing: ≥0.002mm, all depends on OEM required.

4-Surface Treatments:

Grinding, sandblasting, mirror polishing, spray painting, silk screen printing, laser engraving, anodizing, electroplating, chrome plating, powder spraying, etc.

5- Free Samples: 1-10pcs is allowed

6- Lead Time: Orders 5-10days,Samples 10-50days;

7- Packing: pearl cotton/blister box inside and carton/pallet outside

8- Certifications: ISO9001, IATF16949, RoHS, REACH, etc.

9- Production Capacity: 5,000,000 pcs/month

10- Applications: Automobiles, home appliances, monitors, medical care, military, aerospace, etc.

CNC milling of aluminum parts finds extensive applications across various industries due to aluminum's desirable properties such as lightweight, corrosion resistance, and excellent machinability. Some common applications for CNC milled aluminum parts include:

Aerospace: Components for aircraft and spacecraft, including structural elements, brackets, fittings, and housings, are often machined from aluminum due to its lightweight nature and high strength-to-weight ratio.

Automotive: Aluminum parts are used in automotive applications for engine components, transmission housings, suspension parts, brackets, and body panels to reduce weight and improve fuel efficiency.

Electronics: Aluminum parts are widely used in electronic devices and equipment such as enclosures, heat sinks, mounting brackets, and chassis due to their excellent thermal conductivity and electromagnetic shielding properties.

Medical Devices: CNC-machined aluminum parts are used in medical devices and equipment, including surgical instruments, implants, diagnostic tools, and imaging systems, owing to aluminum's biocompatibility and sterilization capabilities.

Consumer Goods: Aluminum parts are found in a wide range of consumer products, including smartphones, laptops, tablets, cameras, audio equipment, and household appliances, for their lightweight, durability, and aesthetic appeal.

Industrial Machinery: Aluminum parts are utilized in various industrial machinery and equipment, including pumps, valves, gears, actuators, conveyor systems, and machine frames, for their strength, stiffness, and corrosion resistance.

Renewable Energy: CNC-machined aluminum components are used in renewable energy systems such as wind turbines, solar panels, and hydroelectric generators for their lightweight construction, corrosion resistance, and structural integrity.

Sporting Goods: Aluminum parts are used in sporting goods and equipment such as bicycles, golf clubs, tennis racquets, fishing reels, and camping gear for their lightweight, durability, and performance characteristics.

Prototype and Custom Parts: CNC milling allows for the rapid prototyping and production of custom aluminum parts for various applications, including research and development, product testing, and one-off manufacturing.

Architectural and Design: Aluminum parts are used in architectural applications such as façades, curtain walls, windows, doors, and structural components for their aesthetic appeal, corrosion resistance, and ease of fabrication.

These are just a few examples of the diverse range of applications for CNC-milled aluminum parts, highlighting the versatility and importance of aluminum as a material in modern manufacturing processes.

Contact Information:

Mr.Terry Young (Sales Director&Technical Engineer)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add: No.225, Jinshang Road, Huli District, Xiamen City, Fujian Province, China, 361009

Mob/WhatsApp/WeChat: 0086-13859903038

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990, professional in Silver Contact & Core & Contact Riveting & Contact Welding & Metal Stamping Solutions for Relay & Switch & Contactor & Breaker, ect!