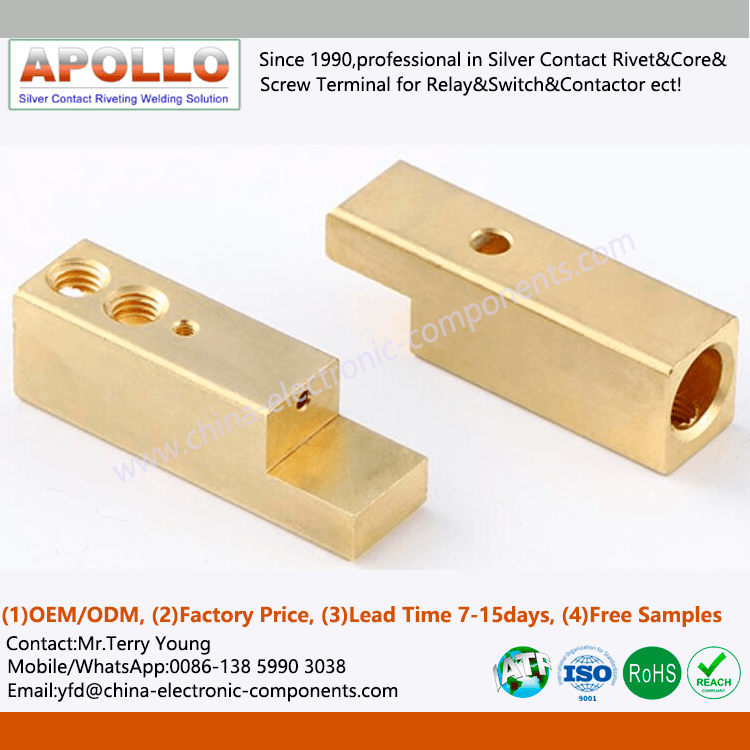

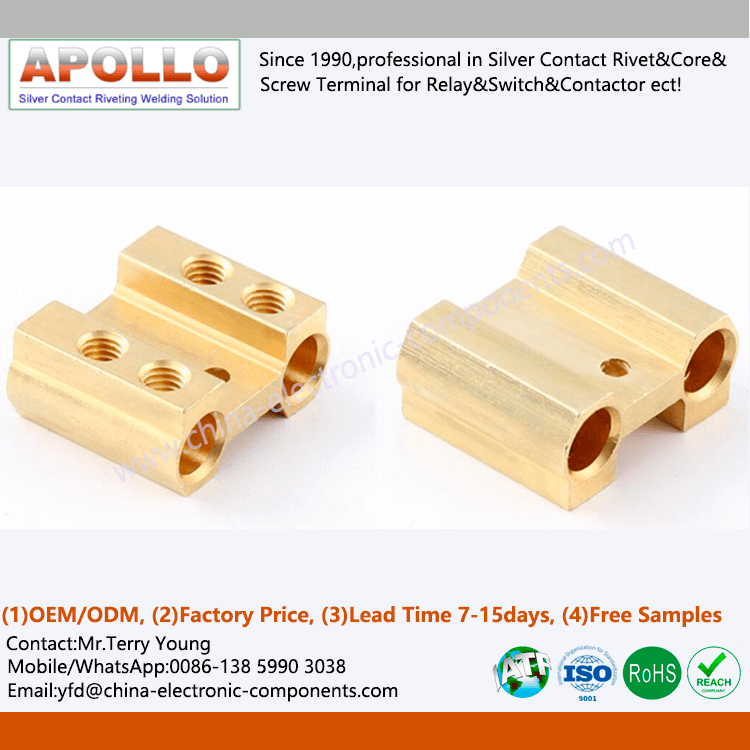

1- Products Name: Machining Brass Parts

2- CNC Machining Metal Parts we can make:

Copper, brass, aluminum alloy, stainless steel, magnesium alloy, titanium alloy, zinc alloy and other metal materials.

3- Dimensional accuracy of processing: ≥0.002mm, all depends on OEM required.

4-Surface Treatments:

Grinding, sandblasting, mirror polishing, spray painting, silk screen printing, laser engraving, anodizing, electroplating, chrome plating, powder spraying, etc.

5- Free Samples: 1-10pcs is allowed

6- Lead Time: Orders 5-10days,Samples 10-50days;

7- Packing: pearl cotton/blister box inside and carton/pallet outside

8- Certifications: ISO9001, IATF16949, RoHS, REACH, etc.

9- Production Capacity: 5,000,000 pcs/month

10- Applications: Automobiles, home appliances, monitors, medical care, military, aerospace, etc.

What principles should be followed in the arrangement of CNC machining sequence?

The arrangement of the processing sequence should be considered according to the structure of the part and the condition of the blank, as well as the need for positioning and clamping. The key point is that the rigidity of the workpiece is not destroyed. The sequence should generally be carried out according to the following principles:

1. The CNC processing of the previous process cannot affect the positioning and clamping of the next process. Comprehensive consideration must also be given to general machine tool processing processes interspersed in the middle.

2. Carry out the inner shape and cavity processing first, and then the outer shape processing.

3. CNC machining processes using the same positioning, clamping method or the same tool are best carried out in succession to reduce the number of repeated positioning, tool changes and platen movements.

4. For multiple processes carried out in the same installation, the process that will cause less rigid damage to the workpiece should be arranged first.

Contact Information:

Mr.Terry Young (Sales Director&Technical Engineer)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add: No.225, Jinshang Road, Huli District, Xiamen City, Fujian Province, China, 361009

Mob/WhatsApp/WeChat: 0086-13859903038

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990, professional in Silver Contact & Core & Contact Riveting & Contact Welding & Metal Stamping Solutions for Relay & Switch & Contactor & Breaker, ect!