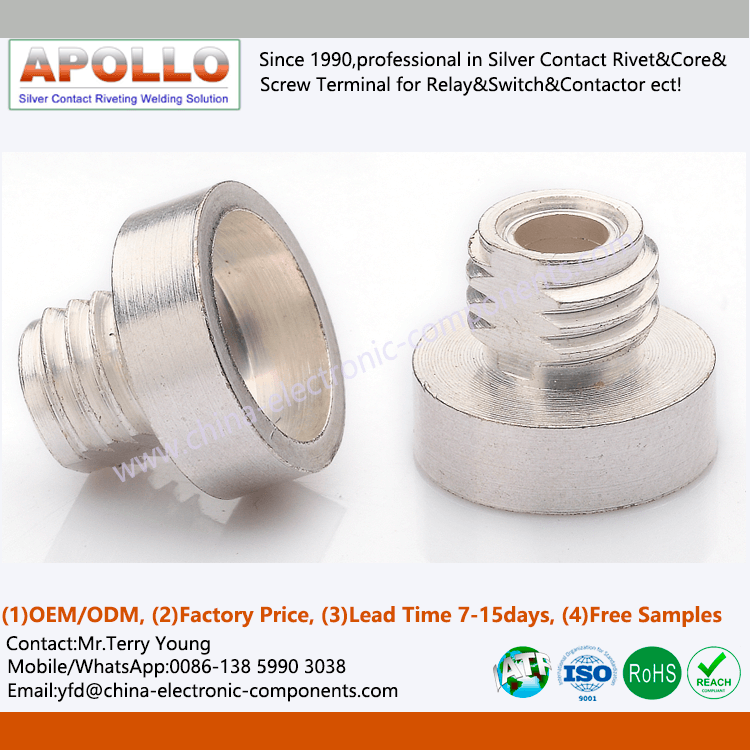

1- Products Name: CNC Machining Stainless Steel Parts

2- CNC Machining Metal Parts we can make:

Copper, brass, aluminum alloy, stainless steel, magnesium alloy, titanium alloy, zinc alloy and other metal materials.

3- Dimensional accuracy of processing: ≥0.002mm, all depends on OEM required.

4-Surface Treatments:

Grinding, sandblasting, mirror polishing, spray painting, silk screen printing, laser engraving, anodizing, electroplating, chrome plating, powder spraying, etc.

5- Free Samples: 1-10pcs is allowed

6- Lead Time: Orders 5-10days,Samples 10-50days;

7- Packing: pearl cotton/blister box inside and carton/pallet outside

8- Certifications: ISO9001, IATF16949, RoHS, REACH, etc.

9- Production Capacity: 5,000,000 pcs/month

10- Applications: Automobiles, home appliances, monitors, medical care, military, aerospace, etc.

How to divide CNC machining processes?

The division of CNC machining processes can generally be carried out according to the following methods:

1. The tool centralized sorting method is to divide the process according to the tools used, and use the same tool to CNC machine all the parts that can be completed. Use the second knife and the third knife to finish other parts they can finish. This can reduce the number of tool changes, compress idle time, and reduce unnecessary positioning errors.

2. Using the processing part sorting method, for parts with a lot of CNC processing content, the processing part can be divided into several parts according to their structural characteristics, such as inner shape, outer shape, curved surface or plane, etc. Generally, planes and positioning surfaces are processed first, and then holes are processed; simple geometric shapes are processed first, and then complex geometric shapes are processed; parts with lower precision are processed first, and then parts with higher precision requirements are processed.

3. Use the rough and fine CNC machining sequence method. For parts that are prone to CNC machining deformation, they need to be calibrated due to the deformation that may occur after rough machining. Therefore, generally speaking, any rough and fine machining must be done in the process. separate. To sum up, when dividing the process, we must consider the structure and craftsmanship of the part, the function of the machine tool, the amount of CNC processing content of the part, the number of installations and the production organization status of the unit. It is also recommended to adopt the principle of process concentration or decentralization, which should be determined according to the actual situation, but it must be reasonable.

Contact Information:

Mr.Terry Young (Sales Director&Technical Engineer)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add: No.225, Jinshang Road, Huli District, Xiamen City, Fujian Province, China, 361009

Mob/WhatsApp/WeChat: 0086-13859903038

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990, professional in Silver Contact & Core & Contact Riveting & Contact Welding & Metal Stamping Solutions for Relay & Switch & Contactor & Breaker, ect!