1- Products Name: Copper and Aluminum Bimetal Bipolar Plate

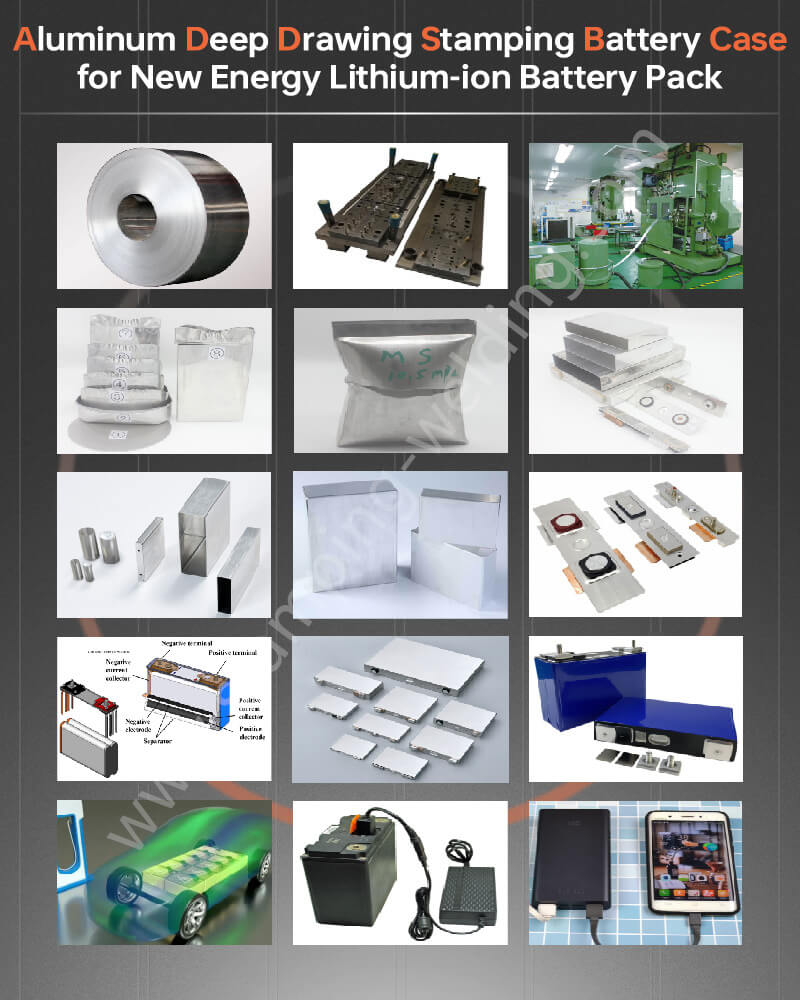

2- Aluminum Case size mainstream specifications for new energy vehicles and energy storage lithium square batteries (wide*long*high by mm):

54173

36130

29135

71173

27148

41255

and so on, all depend on customers' OEM required.

3- Base Material Standard:

(3.1) Battery Aluminum Cases: 3003-H14 Aluminum

Aluminum GB/T3880 standard, Tensile Strength 145-195MPa

(3.2) Battery Cover Plates: 3003-H14 Aluminum & T2Y2 Copper & Plastic Injection

Copper GB/T5231standard, Purity ≥99.99% Copper, Conductivity %IACS≥97, Hardness 80~110HV, Tensile Strength 245-345MPa.

(3.3) Cover Plates Assembly including:

Cover Plate: 3003 H14 Aluminum

Injection Part: PFA Plastic

Electrode Plate: 3003 H14 Aluminum

Positive Pole: 3003 H14 Aluminum

Negative Pole: T2Y2 Copper

Film: 3M PET transparent adhesive

Explosion Proof Valve: MFX2

Positive Connecting Pieces A&B: 1060 H12 Aluminum

Insulating Gasket: PP

Negative Connecting Pieces A&B: T2Y2 Copper+Nickel Plated

4-Surface Treatments:

(4.1) Anodizing

(4.2) Ultrasonic cleaning

5- Production Technologies:

(5.1) Stamping and stretching for Aluminum Battery Prismatic Cases

(5.2) Stamping, injection molding, machining, riveting, resistance welding, laser welding for Battery Cover Plates Assembly

6- Free Samples: 1-10pcs is allowed

7- Lead Time:Orders 10-20days,Samples 20-30days (including the tooling/die production);

8- Packing: pearl cotton/blister box inside and carton/pallet outside

9- Certifications: ISO9001, IATF16949, RoHS, REACH, etc.

10- Production Capacity: 5,000,000 pcs/month

11- Applications: Suitable for electric vehicles, electric motorcycles, electric bicycles, recreational vehicles, golf carts, electric lifts, cleaning vehicles power supplies; energy storage equipment such as forklifts and forklifts: based on solar, wind, geothermal, and ocean energy power generation systems Energy storage equipment; power grid peak shaving; uninterruptible power supply system UPS; used with solar cells as energy storage equipment, home lighting, etc.

Copper and aluminum bimetal bipolar plates are components used in proton exchange membrane fuel cells (PEMFCs), which are a type of fuel cell used in new energy applications such as electric vehicles (EVs), stationary power generation, and portable electronics. Here's a breakdown of their characteristics and significance:

Material Composition: The bipolar plate is a key component in a PEMFC that conducts electricity between adjacent cells, facilitates reactant flow, and removes reaction byproducts. Bimetallic plates combine the beneficial properties of both copper and aluminum:

Copper: Excellent electrical conductivity, corrosion resistance, and formability.

Aluminum: Lightweight, corrosion-resistant, and cost-effective.

Conductivity: Copper is highly conductive, making it ideal for efficiently transporting electrical current within the fuel cell. By utilizing copper in the bimetallic design, the bipolar plate ensures minimal electrical resistance, optimizing the performance of the fuel cell stack.

Corrosion Resistance: Aluminum offers good resistance to corrosion, especially in the acidic environment typical of PEMFCs. Combining aluminum with copper in a bimetallic plate helps mitigate corrosion issues, enhancing the durability and longevity of the bipolar plates.

Weight Reduction: Aluminum's lightweight nature contributes to the overall weight reduction of the fuel cell stack, which is particularly important in mobile applications like EVs where reducing vehicle weight improves energy efficiency and extends driving range.

Thermal Management: The bimetallic design may also help with thermal management within the fuel cell stack. Aluminum's thermal conductivity can aid in dissipating heat generated during the electrochemical reactions, contributing to the overall efficiency and stability of the fuel cell system.

Manufacturability: Bimetallic bipolar plates can be manufactured using various techniques, including diffusion bonding, roll bonding, or cladding, depending on the desired properties and application requirements. These processes allow for precise control over the thickness, composition, and geometry of the plates.

Cost Considerations: By combining copper and aluminum, manufacturers can achieve a balance between performance and cost-effectiveness. While copper is more expensive than aluminum, the bimetallic design offers a cost-efficient solution compared to using pure copper throughout the bipolar plates.

In summary, copper and aluminum bimetal bipolar plates offer a compelling solution for improving the performance, durability, and cost-effectiveness of PEMFCs used in new energy applications. Their unique combination of materials provides a balance of conductivity, corrosion resistance, weight reduction, and thermal management, contributing to the advancement of clean energy technologies.

Contact Information:

Ms.Tina Tian (Sales Manager&Technology Engineer)

Xiamen Apollo Stamping Welding Technology Co., Ltd

Apollo Electronic Components (Xiamen) Co.,Ltd

Add: No.2, Chengyi North Road, Jimei Software Park, Jimei District, Xiamen City, Fujian Province, China, 361022

Mob/WhatsApp/WeChat: 0086-15985814329

Email: tina@stamping-welding.com

Web: www.stamping-welding.com , www.china-electronic-components.com

Since 2010, professional in Metal Stamping & Welding Solutions for New Energy EV & PV Fuse, Battery, Capactior, Relay, Switch, ect!