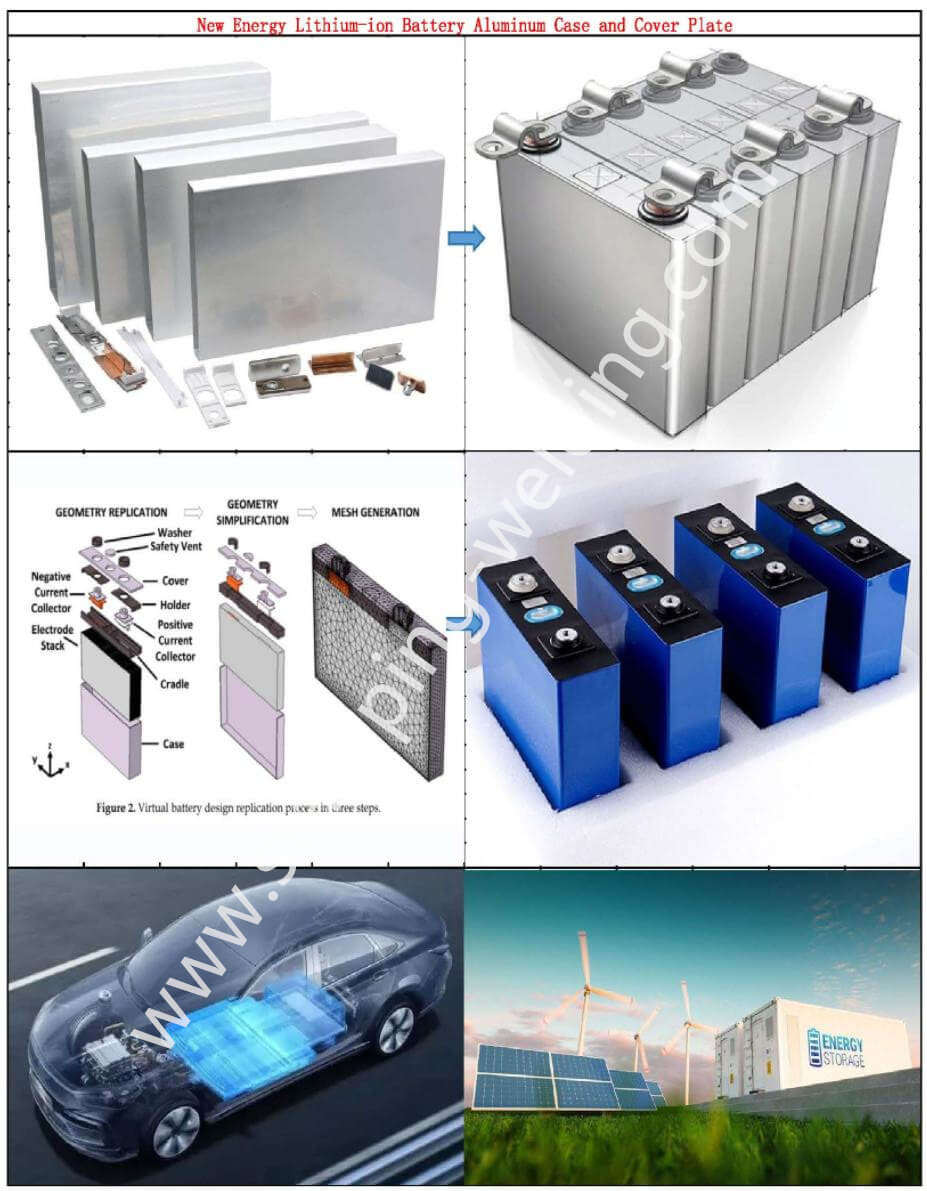

1- Products Name: Polymer Lithium Battery Aluminum Cases

2- Aluminum Case size mainstream specifications for new energy vehicles and energy storage lithium square batteries (wide*long*high by mm):

54173

36130

29135

71173

27148

41255

and so on, all depend on customers' OEM required.

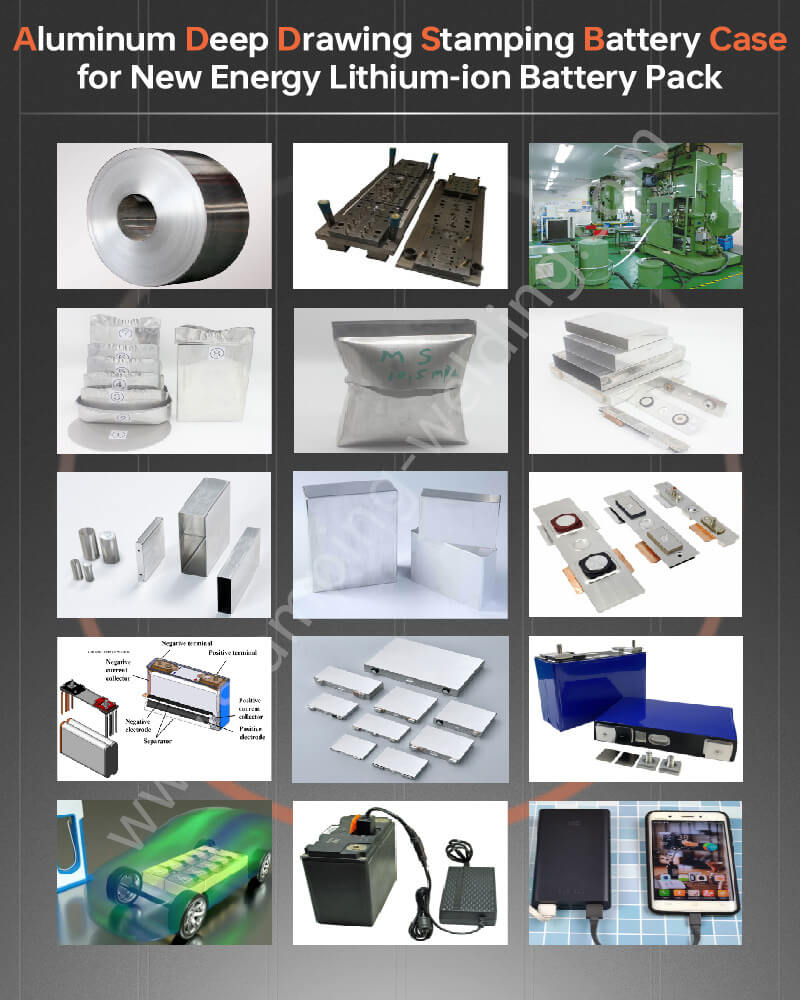

3- Base Material Standard:

(3.1) Battery Aluminum Cases: 3003-H14 Aluminum

Aluminum GB/T3880 standard, Tensile Strength 145-195MPa

(3.2) Battery Cover Plates: 3003-H14 Aluminum & T2Y2 Copper & Plastic Injection

Copper GB/T5231standard, Purity ≥99.99% Copper, Conductivity %IACS≥97, Hardness 80~110HV, Tensile Strength 245-345MPa.

(3.3) Cover Plates Assembly including:

Cover Plate: 3003 H14 Aluminum

Injection Part: PFA Plastic

Electrode Plate: 3003 H14 Aluminum

Positive Pole: 3003 H14 Aluminum

Negative Pole: T2Y2 Copper

Film: 3M PET transparent adhesive

Explosion Proof Valve: MFX2

Positive Connecting Pieces A&B: 1060 H12 Aluminum

Insulating Gasket: PP

Negative Connecting Pieces A&B: T2Y2 Copper+Nickel Plated

4-Surface Treatments:

(4.1) Anodizing

(4.2) Ultrasonic cleaning

5- Production Technologies:

(5.1) Stamping and stretching for Aluminum Battery Prismatic Cases

(5.2) Stamping, injection molding, machining, riveting, resistance welding, laser welding for Battery Cover Plates Assembly

6- Free Samples: 1-10pcs is allowed

7- Lead Time:Orders 10-20days,Samples 20-30days (including the tooling/die production);

8- Packing: pearl cotton/blister box inside and carton/pallet outside

9- Certifications: ISO9001, IATF16949, RoHS, REACH, etc.

10- Production Capacity: 5,000,000 pcs/month

11- Applications: Suitable for electric vehicles, electric motorcycles, electric bicycles, recreational vehicles, golf carts, electric lifts, cleaning vehicles power supplies; energy storage equipment such as forklifts and forklifts: based on solar, wind, geothermal, and ocean energy power generation systems Energy storage equipment; power grid peak shaving; uninterruptible power supply system UPS; used with solar cells as energy storage equipment, home lighting, etc.

Polymer lithium battery aluminum cases are protective enclosures made of aluminum designed to house and safeguard polymer lithium-ion battery cells. Here's a breakdown of their characteristics and significance:

Encapsulation and Protection: Aluminum cases provide a robust barrier around polymer lithium-ion battery cells, shielding them from external impacts, mechanical stress, and environmental factors. They prevent physical damage to the delicate internal components of the battery cells, ensuring their integrity and longevity.

Structural Integrity: Aluminum cases contribute to the overall structural integrity of the battery pack. They help maintain the shape and stability of the battery cells, ensuring that they remain securely housed and properly aligned within the pack.

Thermal Management: Aluminum is an excellent conductor of heat, allowing for efficient dissipation of heat generated during charging and discharging cycles. Aluminum cases help regulate the temperature of the battery cells, preventing overheating and thermal runaway, which can degrade battery performance and pose safety risks.

Lightweight Design: Aluminum cases offer a lightweight solution for battery packs, which is particularly important for portable and mobile applications. They help reduce the overall weight of the battery pack, making it easier to handle, transport, and integrate into various devices and systems.

Corrosion Resistance: Aluminum exhibits natural corrosion resistance, which helps protect the battery cells from moisture, humidity, and other corrosive elements. Aluminum cases ensure the long-term durability and reliability of the battery pack in diverse environmental conditions.

Hermetic Sealing: Polymer lithium battery aluminum cases can be designed with features to create a hermetic seal, preventing the ingress of moisture, dust, and contaminants into the battery pack. Hermetic sealing preserves the integrity of the internal components and ensures reliable performance over time.

Customization and Integration: Aluminum cases can be customized to fit specific battery cell configurations and pack designs. They are designed to integrate seamlessly with other components of the battery pack, such as electrical connections, cooling systems, and safety features.

Manufacturability: Aluminum cases can be manufactured using various techniques, including extrusion, stamping, and machining. This allows for precise fabrication and customization of battery pack designs, enabling the production of packs with different sizes, shapes, and capacities to meet specific application requirements.

In summary, polymer lithium battery aluminum cases play a crucial role in ensuring the safety, reliability, and performance of battery packs used in various applications, including portable electronics, electric vehicles, and energy storage systems. Their protection, structural integrity, thermal management, lightweight design, corrosion resistance, hermetic sealing, customization, and manufacturability features are essential for optimizing the functionality and longevity of polymer lithium-ion batteries.

Contact Information:

Ms.Tina Tian (Sales Manager&Technology Engineer)

Xiamen Apollo Stamping Welding Technology Co., Ltd

Apollo Electronic Components (Xiamen) Co.,Ltd

Add: No.2, Chengyi North Road, Jimei Software Park, Jimei District, Xiamen City, Fujian Province, China, 361022

Mob/WhatsApp/WeChat: 0086-15985814329

Email: tina@stamping-welding.com

Web: www.stamping-welding.com , www.china-electronic-components.com

Since 2010, professional in Metal Stamping & Welding Solutions for New Energy EV & PV Fuse, Battery, Capactior, Relay, Switch, ect!