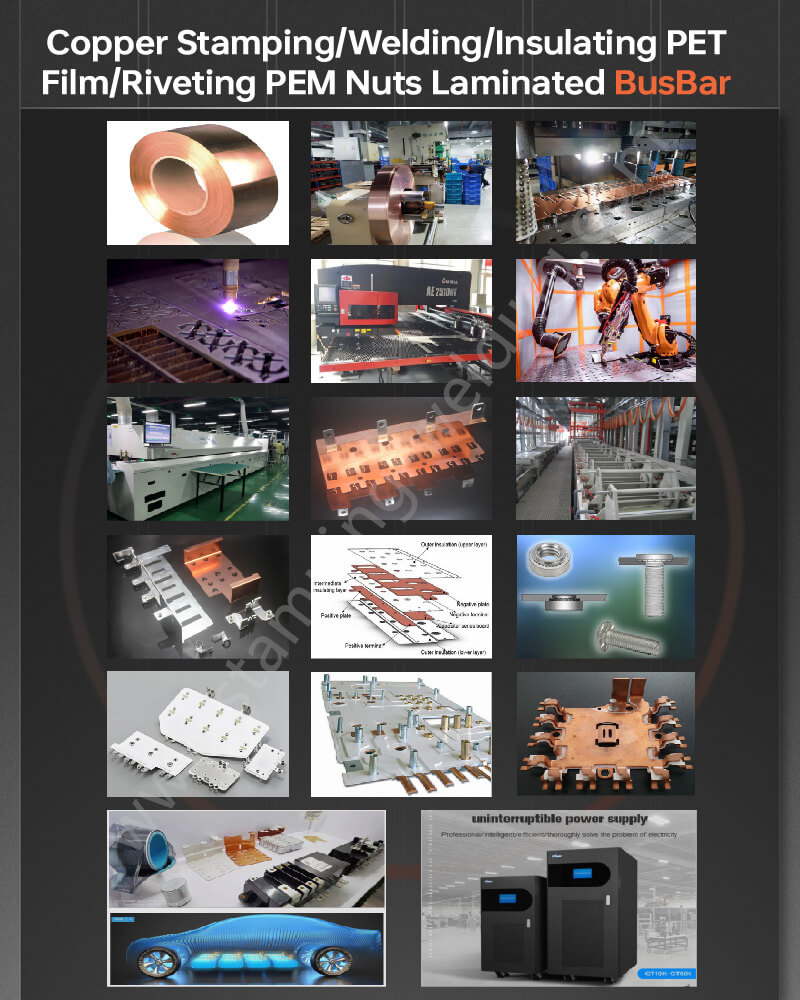

1- Products Name: Insulation Flexible BusBar

2- Base Material Standard:

GB: T2Y2 Copper Foils / Sheet

(2.1) Copper Foils Thickness: 0.1mm, 0.2mm, 0.3mm, 0.5mm, 1.0mm

(2.2) Copper Flexible BusBar long up to 6.6 ft (2meters long)

(2.3) Copper Flexible BusBar width up to 6.0 inch (152mm)

(2.4) Laminated Copper Foil thickness up to 1.25 inch (32mm)

DIN: E-Cu58 (Number: 2.0065)

EN: Cu-ETP ( Number: CW004A)

ISO: Cu-ETP

UNS: C11000

JIS: C1100

BS: C101

Purity ≥99.99% Copper, Conductivity %IACS≥97, Hardness 80~110HV, Tensile Strength 245-345MPa, other material also can be customized.

3-Surface Treatments:

(3.1) Silver plating

(3.2) Tin plating

(3.3) Nickel plating or Resistance diffusion welding nickel sheet

(3.4) Ultrasonic cleaning

Normally plated thickness is 3μm to 12μm, but all upon customers' request.

4- Insulation Options:

(4.1) PET insulation paper (brands USA GTS, GERMANY KREMPEL, etc with white or milky white colors)

(4.2) PVC dipping (orange and green are the most popular colors)

(4.3) Epoxy powder coating (orange, green and grey are the most popular colors)

(4.4) PE heat shrink tube (orange, green, black, red are yellow are the most popular colors)

(4.5) PA66 plastic housing (white, grey etc are the most popular colors)

Flame Retardant / Fire Resistance: UL94-V-0 or upon you request;

Operating Temperature: -45ºC to +150 ºC

5- Copper Busbar Resistance: ≤0.00001Ω

6- Copper Busbar load voltage 3500VDC to 5000VDC and current 100A to 2000A

7- Copper Busbar Assembly Fixtures: USA PEM stainless nuts, studs, standoffs, screws, etc

8- Free Samples:1-10pcs is allowed

9- Lead Time:Orders 7-10days,Samples 10-20days(including the tooling/die production of Copper Stamped Part);

10- Packing: pearl cotton/blister box inside and carton/pallet outside

11- Certifications: ISO9001, IATF16949, RoHS, REACH, etc.

12- Production Capacity: 50,000,000 pcs/month

13- Applications: film capacitors for new energy electric vehicles and hybrid vehicles, new energy vehicle battery packs, new energy photovoltaic energy storage, power appliances, distribution cabinets, rail transit, cloud server uninterruptible power supplies and other power systems.

Insulation flexible busbars used in EV (electric vehicle) battery packs play a critical role in ensuring the safety and efficiency of the battery system. Here are key considerations and features related to the design and application of insulation flexible busbars in EV battery packs:

1.Material Selection:

The insulation material used in flexible busbars for EV battery packs is chosen for its electrical insulation properties, thermal performance, and resistance to environmental factors. Common insulation materials include flexible insulating films or layers made of materials such as polyimide or polyester.

2.Flexibility and Conformability:

Insulation flexible busbars are designed to be flexible and conformable to accommodate the layout and structure of the battery pack. The flexibility allows for easy installation, especially in tight spaces within the battery enclosure.

3.Dielectric Strength:

The insulation material must have a high dielectric strength to effectively prevent electrical arcing or short circuits between adjacent conductive elements. This is crucial for maintaining the integrity of the electrical insulation within the battery pack.

4.Thermal Resistance:

Given the potential for heat generation in EV battery packs, the insulation material should have good thermal resistance. This helps in preventing heat transfer between adjacent conductive elements and ensures that the insulation remains effective even in elevated temperature conditions.

5.Resistance to Environmental Factors:

Copper Flexible BusBars are exposed to various environmental factors, including moisture, chemicals, and vibrations. The chosen insulation material should be resistant to these factors to maintain its effectiveness over the lifespan of the battery pack.

6.Customized Shapes and Sizes:

Flexible busbars can be customized to fit the specific layout and design of the EV battery pack. This involves precision cutting and shaping of the insulation material to match the arrangement of the battery cells and components.

The design and selection of insulation materials for flexible busbars in EV battery packs involve a balance between electrical performance, thermal management, and safety considerations. Manufacturers follow industry standards and guidelines to produce insulation flexible busbars that meet the demanding requirements of electric vehicles.

Contact Information:

Ms.Tina Tian (Sales Manager&Technology Engineer)

Xiamen Apollo Stamping Welding Technology Co., Ltd

Apollo Electronic Components (Xiamen) Co.,Ltd

Add: No.2, Chengyi North Road, Jimei Software Park, Jimei District, Xiamen City, Fujian Province, China, 361022

Mob/WhatsApp/WeChat: 0086-15985814329

Email: tina@stamping-welding.com

Web: www.stamping-welding.com , www.china-electronic-components.com

Since 2010, professional in Metal Stamping & Welding Solutions for New Energy EV & PV Fuse, Battery, Capactior, Relay, Switch, ect!