1- Products Name: Epoxy Coating Powder Busbar

2- Base Material Standard:

GB : T2Y2 Copper

DIN: E-Cu58 (Number: 2.0065)

EN: Cu-ETP ( Number: CW004A)

ISO: Cu-ETP

UNS: C11000

JIS: C1100

BS: C101

Purity ≥99.99% Copper, Conductivity %IACS≥97, Hardness 80~110HV, Tensile Strength 245-345MPa, other material also can be customized.

3-Surface Treatments:

(3.1) Silver plating

(3.2) Tin plating

(3.3) Nickel plating

(3.4) Ultrasonic cleaning

Normally plated thickness is 3μm to 12μm, but all upon customers' request.

4- Insulation Options:

(4.1) PET insulation paper (brands USA GTS, GERMANY KREMPEL, etc with white or milky white colors)

(4.2) PVC dipping (orange and green are the most popular colors)

(4.3) Epoxy powder coating (orange, green and grey are the most popular colors)

(4.4) PE heat shrink tube (orange, green, black, red are yellow are the most popular colors)

Flame Retardant / Fire Resistance: UL94-V-0 or upon you request;

Operating Temperature: -45ºC to +150 ºC

5- Copper Busbar Resistance: ≤0.00001Ω

6- Copper Busbar load voltage 3500VDC to 5000VDC and current 100A to 2000A

7- Copper Busbar Assembly Fixtures: USA PEM stainless nuts, studs, standoffs, screws, etc

8- Free Samples:1-10pcs is allowed

9- Lead Time:Orders 7-10days,Samples 10-20days(including the tooling/die production of Copper Stamped Part);

10- Packing: pearl cotton/blister box inside and carton/pallet outside

11- Certifications: ISO9001, IATF16949, RoHS, REACH, etc.

12- Production Capacity: 50,000,000 pcs/month

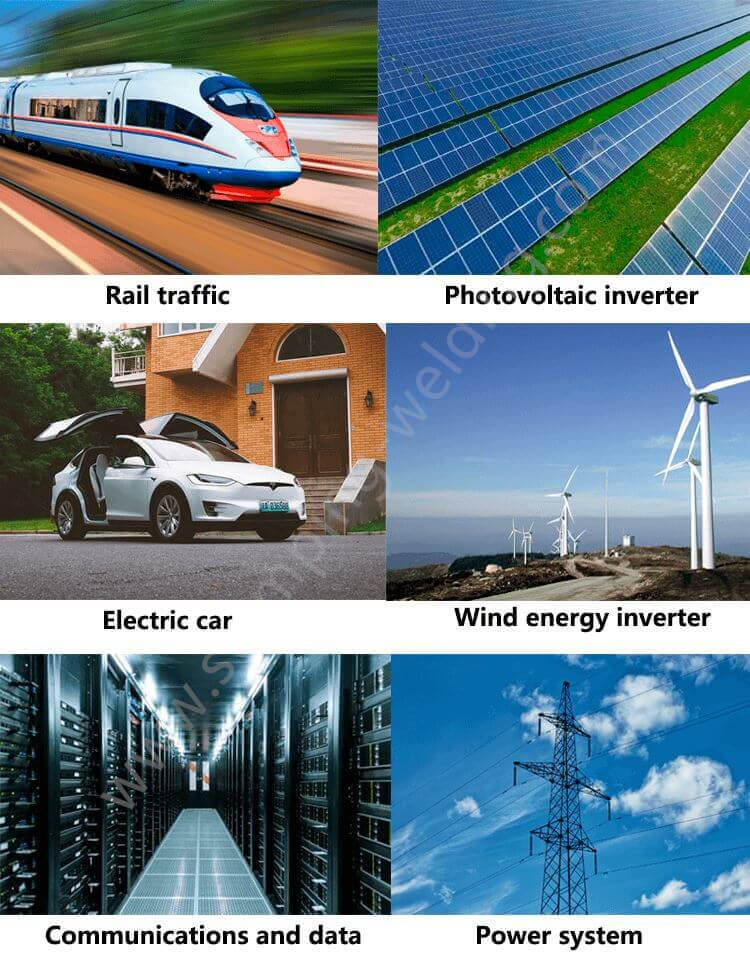

13- Applications: film capacitors for new energy electric vehicles and hybrid vehicles, new energy vehicle battery packs, new energy photovoltaic energy storage, power appliances, distribution cabinets, rail transit, cloud server uninterruptible power supplies and other power systems.

The manufacturing processes of epoxy coating powder busbars involve several steps to ensure the application of a uniform and durable epoxy coating. Here's an overview of the typical manufacturing processes for epoxy-coated busbars:

1. Copper Busbar Fabrication:

Material Selection: Busbars are typically fabricated from highly conductive materials such as copper or aluminum. The selected material depends on the application and electrical requirements.

2. Copper Busbar Surface Cleaning and Preparation:

Degreasing: The busbars undergo a thorough cleaning process to remove any contaminants, oils, or impurities from the surface. This is often done through degreasing to ensure proper adhesion of the epoxy coating.

3. Copper Busbar Epoxy Powder Formulation:

Epoxy Powder Composition: The epoxy powder formulation is prepared, considering factors such as electrical insulation requirements, corrosion resistance, and environmental durability. The formulation may include epoxy resins, curing agents, pigments, and other additives.

4. Copper Busbar Powder Coating Application:

Electrostatic Spraying: The cleaned busbars are subjected to an electrostatic spraying process. Epoxy powder is applied to the surface of the busbars, and the electrostatic charge ensures uniform coverage, including edges and corners.

Powder Booths and Guns: Automated powder coating equipment, such as powder booths and guns, may be used to efficiently and precisely apply the epoxy powder.

5. Copper Busbar Curing Process:

Heat Curing: After the epoxy powder is applied, the busbars are subjected to a curing process. This involves heating the busbars to a specific temperature for a defined period, allowing the epoxy powder to melt, flow, and cure into a solid, continuous coating.

Time and Temperature Control: Precise control over the curing temperature and duration is crucial to ensure proper cross-linking of the epoxy molecules and the formation of a durable coating.

6. Copper Busbar Cooling and Inspection:

Cooling: The epoxy-coated busbars are cooled after the curing process to set the coating.

Quality Inspection: The coated busbars undergo thorough quality inspection to ensure the uniformity of the coating, absence of defects, and compliance with specified thickness requirements.

7. Copper Busbar Cutting and Shaping:

Precision Cutting: The coated busbars are cut and shaped according to the specific requirements of the application. This may involve creating different lengths, angles, or configurations.

Testing:

Electrical Testing: The epoxy-coated busbars undergo electrical testing to ensure that the insulation properties meet specified standards and requirements.

Adhesion Testing: Adhesion tests may be conducted to verify the strength of the bond between the epoxy coating and the substrate material.

8. Copper Busbar Packaging and Shipping:

Once the epoxy coating is applied, cured, and passes quality control tests, the busbars are packaged for shipment to end-users or further integration into electrical systems.

It's important to note that the specific details of the manufacturing process may vary based on the equipment used, the scale of production, and the requirements of the application. Manufacturers often follow industry standards and best practices to ensure the reliability and performance of epoxy-coated busbars.

Contact Information:

Ms.Tina Tian (Sales Manager&Technology Engineer)

Xiamen Apollo Stamping Welding Technology Co., Ltd

Apollo Electronic Components (Xiamen) Co.,Ltd

Add: No.2, Chengyi North Road, Jimei Software Park, Jimei District, Xiamen City, Fujian Province, China, 361022

Mob/WhatsApp/WeChat: 0086-15985814329

Email: tina@stamping-welding.com

Web: www.stamping-welding.com , www.china-electronic-components.com

Since 2010, professional in Metal Stamping & Welding Solutions for New Energy EV & PV Fuse, Battery, Capactior, Relay, Switch, ect!