1- Products Name: Ground Bus Bar with Nut

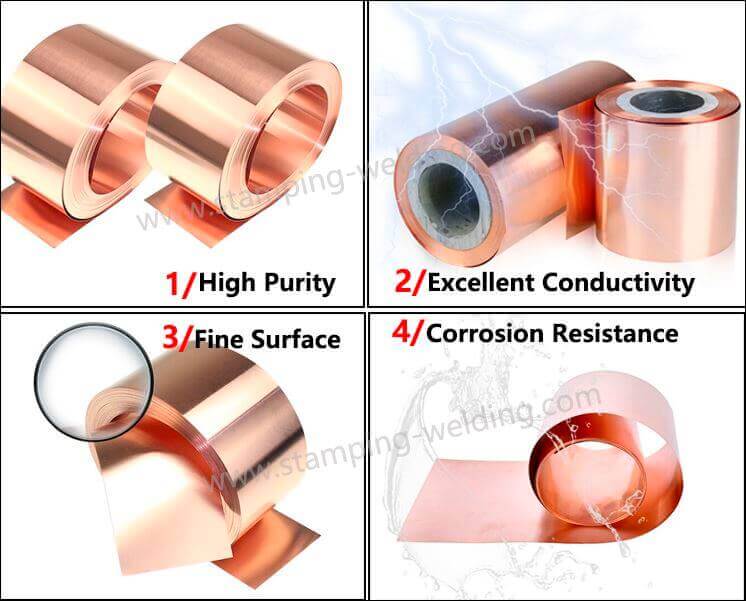

2- Base Material Standard:

GB : T2Y2 Copper

DIN: E-Cu58 (Number: 2.0065)

EN: Cu-ETP ( Number: CW004A)

ISO: Cu-ETP

UNS: C11000

JIS: C1100

BS: C101

Purity ≥99.99% Copper, Conductivity %IACS≥97, Hardness 80~110HV, Tensile Strength 245-345MPa, other material also can be customized.

3-Surface Treatments:

(3.1) Silver plating

(3.2) Tin plating

(3.3) Nickel plating

(3.4) Ultrasonic cleaning

Normally plated thickness is 3μm to 12μm, but all upon customers' request.

4- Insulation Options:

(4.1) PET insulation paper (brands USA GTS, GERMANY KREMPEL, etc with white or milky white colors)

(4.2) PVC dipping (orange and green are the most popular colors)

(4.3) Epoxy powder coating (orange, green and grey are the most popular colors)

(4.4) PE heat shrink tube (orange, green, black, red are yellow are the most popular colors)

Flame Retardant / Fire Resistance: UL94-V-0 or upon you request;

Operating Temperature: -45ºC to +150 ºC

5- Copper Busbar Resistance: ≤0.00001Ω

6- Copper Busbar load voltage 3500VDC to 5000VDC and current 100A to 2000A

7- Copper Busbar Assembly Fixtures: USA PEM stainless nuts, studs, standoffs, screws, etc

8- Free Samples:1-10pcs is allowed

9- Lead Time:Orders 7-10days,Samples 10-20days(including the tooling/die production of Copper Stamped Part);

10- Packing: pearl cotton/blister box inside and carton/pallet outside

11- Certifications: ISO9001, IATF16949, RoHS, REACH, etc.

12- Production Capacity: 50,000,000 pcs/month

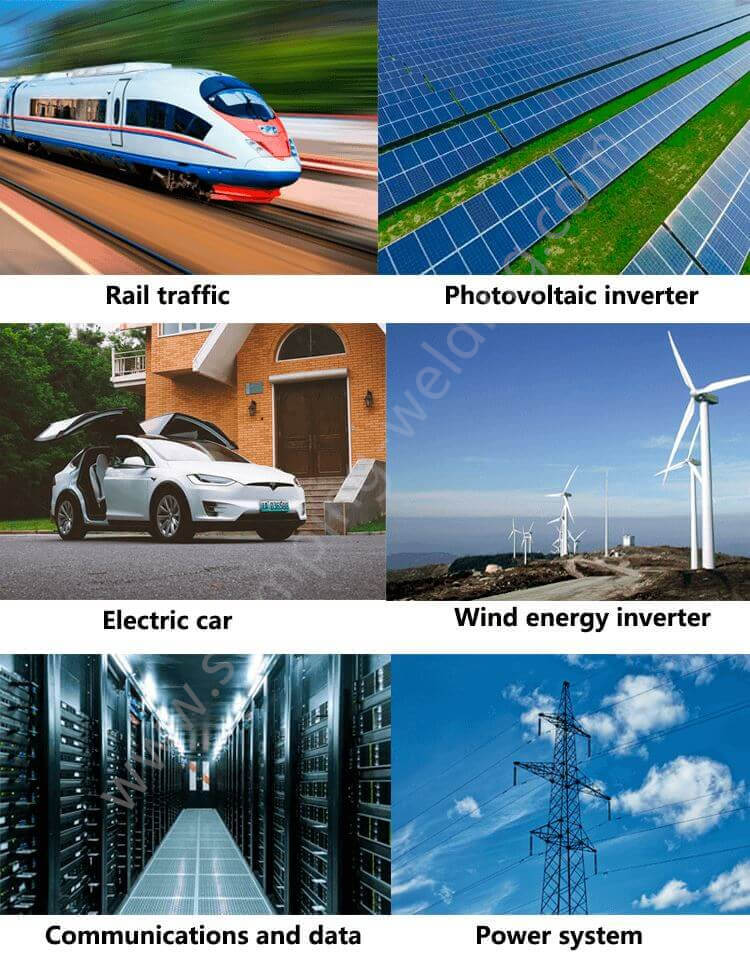

13- Applications: film capacitors for new energy electric vehicles and hybrid vehicles, new energy vehicle battery packs, new energy photovoltaic energy storage, power appliances, distribution cabinets, rail transit, cloud server uninterruptible power supplies and other power systems.

Copper ground bus bars are commonly used in earthing systems for various applications. The grounding or earthing system is designed to provide a low-resistance path for electrical currents to flow into the ground, ensuring safety and protecting equipment from electrical faults. Here are key aspects related to the use of copper ground bus bars in earthing systems:

1-Copper Grounding Busbar Material Selection:

Copper Conductivity: Copper is chosen for ground bus bars due to its excellent electrical conductivity. It provides a low-resistance path for fault currents to dissipate into the ground.

Corrosion Resistance: Copper exhibits good corrosion resistance, contributing to the longevity and reliability of the grounding system.

2-Copper Grounding Bus Bar Design:

Flat or Tubular Design: Copper ground bus bars may have a flat or tubular design, depending on the application and the specific requirements of the earthing system.

Multiple Connections: Ground bus bars are designed to accommodate multiple connections from various grounding conductors, creating a centralized point for grounding.

3-Installation in Electrical Panels:

Main Grounding Bus Bar: In electrical panels, a copper ground bus bar serves as the main grounding point, providing a common connection for grounding conductors from circuits and equipment.

Bonding Connections: The ground bus bar facilitates the bonding of metallic components, ensuring that all exposed metal parts are connected to the ground for safety.

4-Connection to Ground Electrodes:

Grounding Electrodes: Copper ground bus bars are connected to grounding electrodes, such as grounding rods or plates, to establish a low-impedance path to the earth.

Low Resistance Path: The goal is to create a low-resistance path for fault currents to flow into the ground, preventing the buildup of dangerous voltages.

5-Substation Grounding:

Substation Applications: In electrical substations, copper ground bus bars are integral to the grounding system. They provide a centralized point for connecting grounding conductors from various equipment.

Grid Grounding: Copper bus bars contribute to the overall grounding of the electrical grid, ensuring the safety of personnel and protecting equipment from transient overvoltages.

6-Lightning Protection:

Lightning Grounding: Copper ground bus bars are essential for grounding systems designed to dissipate lightning-induced currents. They help direct the energy from lightning strikes safely into the ground.

Testing and Maintenance:

Periodic Testing: Grounding systems, including copper ground bus bars, should undergo periodic testing to ensure their effectiveness in providing low resistance to ground.

Maintenance Checks: Regular maintenance checks involve inspecting connections, ensuring corrosion resistance, and verifying that the grounding system meets safety standards.

7-Compliance with Standards:

Adherence to Standards: The design and installation of copper ground bus bars in earthing systems should adhere to relevant electrical codes and standards to ensure safety and compliance.

Copper ground bus bars play a critical role in establishing an effective and reliable earthing system, contributing to electrical safety and the protection of equipment in various applications.

Contact Information:

Ms.Tina Tian (Sales Manager&Technology Engineer)

Xiamen Apollo Stamping Welding Technology Co., Ltd

Apollo Electronic Components (Xiamen) Co.,Ltd

Add: No.2, Chengyi North Road, Jimei Software Park, Jimei District, Xiamen City, Fujian Province, China, 361022

Mob/WhatsApp/WeChat: 0086-15985814329

Email: tina@stamping-welding.com

Web: www.stamping-welding.com , www.china-electronic-components.com

Since 2010, professional in Metal Stamping & Welding Solutions for New Energy EV & PV Fuse, Battery, Capactior, Relay, Switch, ect!