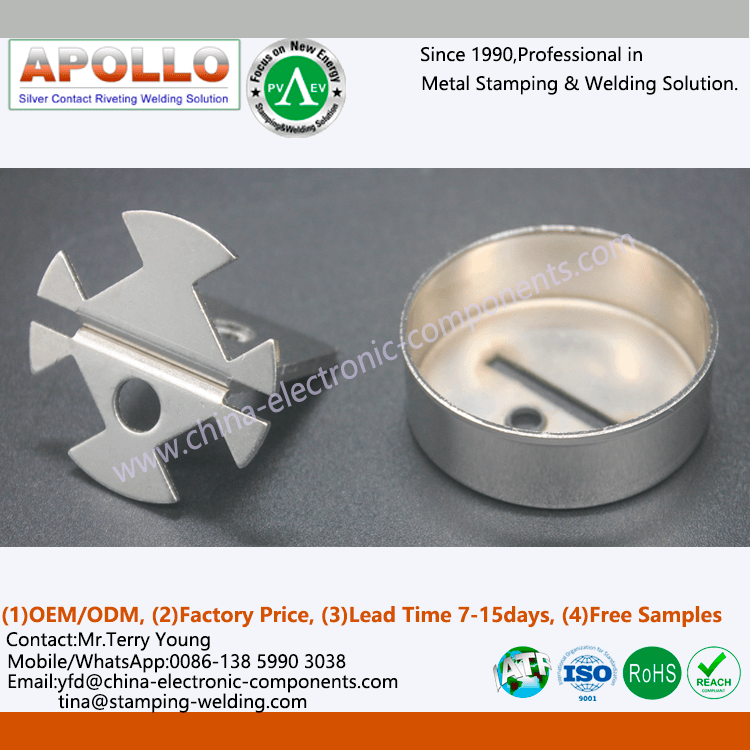

1-Products Name: Fuse Contact Knife Cap for Volkswagen Automotive

2-Base Material:

(1)Red Copper Stamping Parts:99.99% Copper T2Y2(SECu/C1100) ,%IACS≥97,HV:80~110s;

(2)Brass Stamping Parts:65% Brass H65(CuZn36/C2700),tensile strengthσb MPa≥440

3-Surface Treatments:

(1)Silver plating

(2)Bright tin plating

(3)Lead-free fog tin plating

(4)Nickel plating

(5)Ultrasonic cleaning

4-Free Samples:10-50pcs is allowed

5-Lead Time:Orders 7-10days,Samples 20-25days(including the tooling/die production of Copper Stamped Part);

6-Packing: Plastic inside and carton/pallet outside

7-Certifications: ISO9001,IATF16949,RoHS,REACH,etc.

8-Production Capacity: 50,000,000 pcs/month

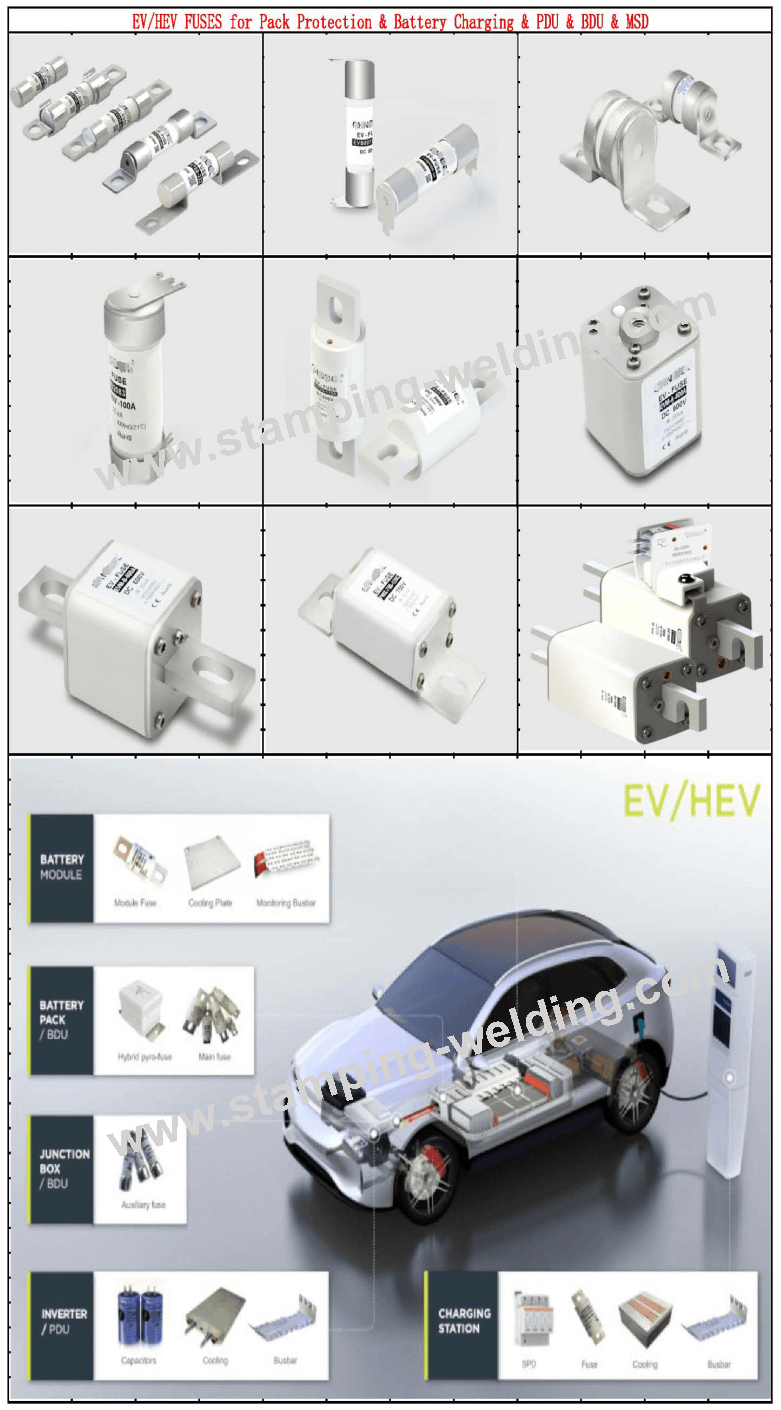

9-Applications:PV Fuse,EV Fuse,PDU Fuse,Energy Storage Fuse,UPS DC Links,NH Fuse,BS Fuse,Fast Fuse,etc.

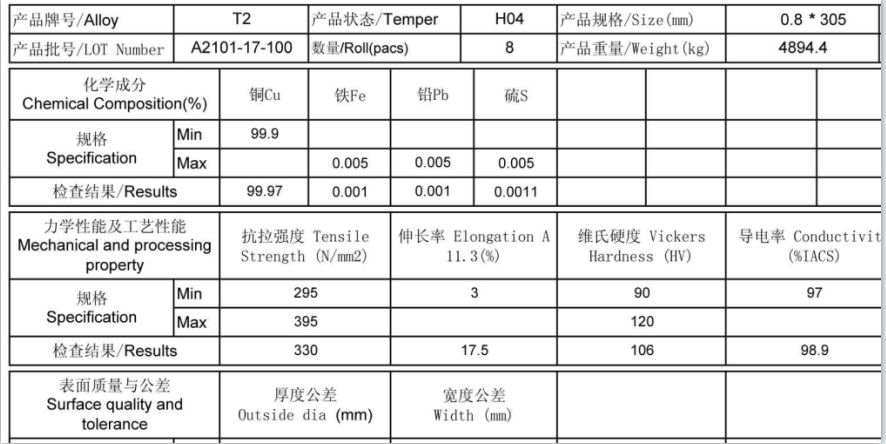

T2Y2 Red Copper Contact for Fuse material properties

1.The copper of Fuse Terminal Contact has good electrical conductivity, thermal conductivity, corrosion resistance and processing properties, and Fuse Terminal can be welded and brazed. Contains less impurities that reduce electrical conductivity and thermal conductivity, and trace oxygen has little effect on electrical conductivity, thermal conductivity and processing properties.

2.The copper terminal of EV Automotive Fuse Terminals High purity, conductivity not less than 98%.

3.The Copper of Fuse Terminal Contact is No "hydrogen disease" or very little "hydrogen disease"; good processing performance and welding, corrosion resistance and cold resistance.

4.Fuse Link Contact Copper material has good welding performance and cold bending performance, generally no "hydrogen disease" tendency, can be processed and used in a reducing atmosphere.

5.The addition of a small amount of silver to copper can significantly increase the softening temperature (recrystallization temperature) and creep strength, with little reduction in copper electrical conductivity, thermal conductivity and plasticity. The aging hardening effect of silver copper is not significant, and cold work hardening is generally used to improve the strength. The copper terminal of Fuse End Blade Ferrules has good wear resistance, electrical contact and corrosion resistance.

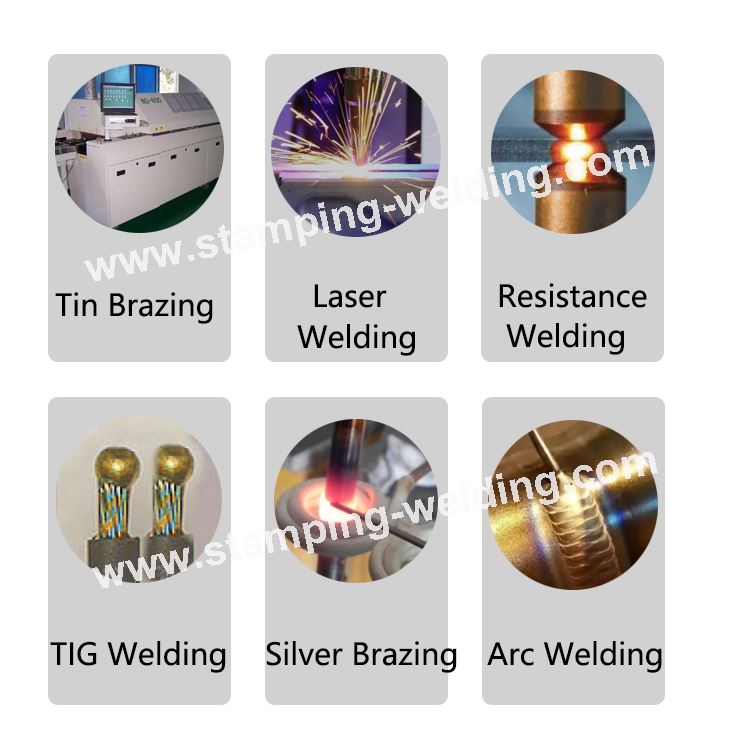

Brazing inspection methods for the Fuse Copper End Caps and Contact

⒈ Visual inspection

The visual inspection is to check the surface quality of the brazed joint Copper Pipe Cap with the naked eyes or a low-magnification magnifying glass, such as whether the solder fills the gap, whether the exposed end of the brazing seam forms a fillet, whether the fillet is uniform, whether the surface is smooth, whether there are cracks, pores and other external defects.

2. Surface defect inspection

Surface defect inspection methods of Copper Pipe End Cap include fluorescence inspection (color inspection) and magnetic particle inspection. They are used for inspection of appearance and for inspection of brazing surface defects such as cracks, porosity, etc., which cannot be detected visually. Fluorescence inspection is generally used for the inspection of small workpieces like Fuse Copper Cap, color inspection (partial inspection of workpieces) for large workpieces like Copper Cap for European Cylindrical Fuse Link, and magnetic particle inspection is only used for magnetic metals.

⒊Internal defect inspection

Radiographic inspection, ultrasonic inspection and compactness inspection are mainly used for Plated End Caps,like Silver-plated Copper End Caps ,Fog Tin-plated Copper End Caps,Bright Tin-plated Copper End Caps,and so on.Radiographic inspection is a common method for inspecting the internal defects of important workpieces Copper Outer Cap for Eaton Bussmann Fuse. It can show pores, slag inclusions, lack of brazing in the brazing seam, and cracking of the brazing seam and the base metal Fuse Outer Cap. The range of defects found by ultrasonic inspection is the same as that of radiographic inspection.

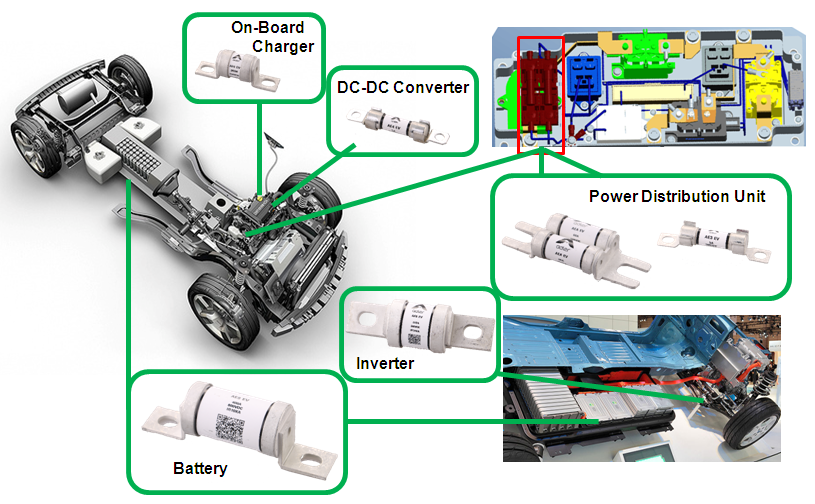

Application of new energy vehicle fuse

EV electric vehicle fuse: The EV fuse with End Cap and Contact used in electric vehicles not only needs the fuse protection performance of DC high-voltage fuses in ordinary power distribution systems, but also needs to withstand the shock and vibration of road vehicles. A unique class of requirements for the Contact Knife Cap Fuse used.At present, the working voltage of passenger cars is generally above 370V, and that of buses is above 576V, which is much higher than the 12V/24V of traditional automotive electrical components. Such a high working platform voltage requires End Cap Terminal EV/HEV fuses to have both the high breaking capacity of low-voltage fuses and the high reliability of automotive fuses with Outer Cap Contact.In addition to the power battery main fuse, there are also automotive air conditioning systems, heating systems, and DC/DC systems (converting the power battery voltage to 14 V to provide the vehicle Low-voltage power supply, similar to generator) and other accessory high-voltage circuits, each circuit needs to be connected in series with a DC high-voltage Copper Cap Contact Fuse for circuit protection.

In the high-voltage distribution box of an electric vehicle, the output terminal is mainly connected to the auxiliary power supply system of the vehicle, and the inside of the distribution box generally includes an electric heating fan branch, an air-conditioning compressor branch, a DC/DC branch and a charger branch. These four branches, each branch needs to install line protection Knife Contact Fuse, the purpose is to cut off the power protection circuit in time when each load is short-circuited, and avoid vehicle fire. With the comprehensive advantages of small size, good shock resistance and low price, fuses have been widely recognized and used in large quantities, and have become the main components Fuse Terminal recognized at home and abroad as the short-circuit protection of electric vehicles.

For the Copper Contact Cap fuse standard system, it is mainly divided into IEC standard, UL standard and ISO standard. Among them, Chinese GB, German DIN and British BS basically adopt IEC standard. IEC standards mainly include IEC 60127, IEC 60269, etc. UL mainly includes UL248, etc. ISO mainly includes ISO 8820 series.

Contact Information:

Mr.Terry Young (Sales Manager&Technology Engineer)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact&Contact Riveted Set&Contact Brazed Set&Screw Terminal Set&Metal Stamping for Relay&Switch&Contactor&Breaker&EV PV Fuse,ect!