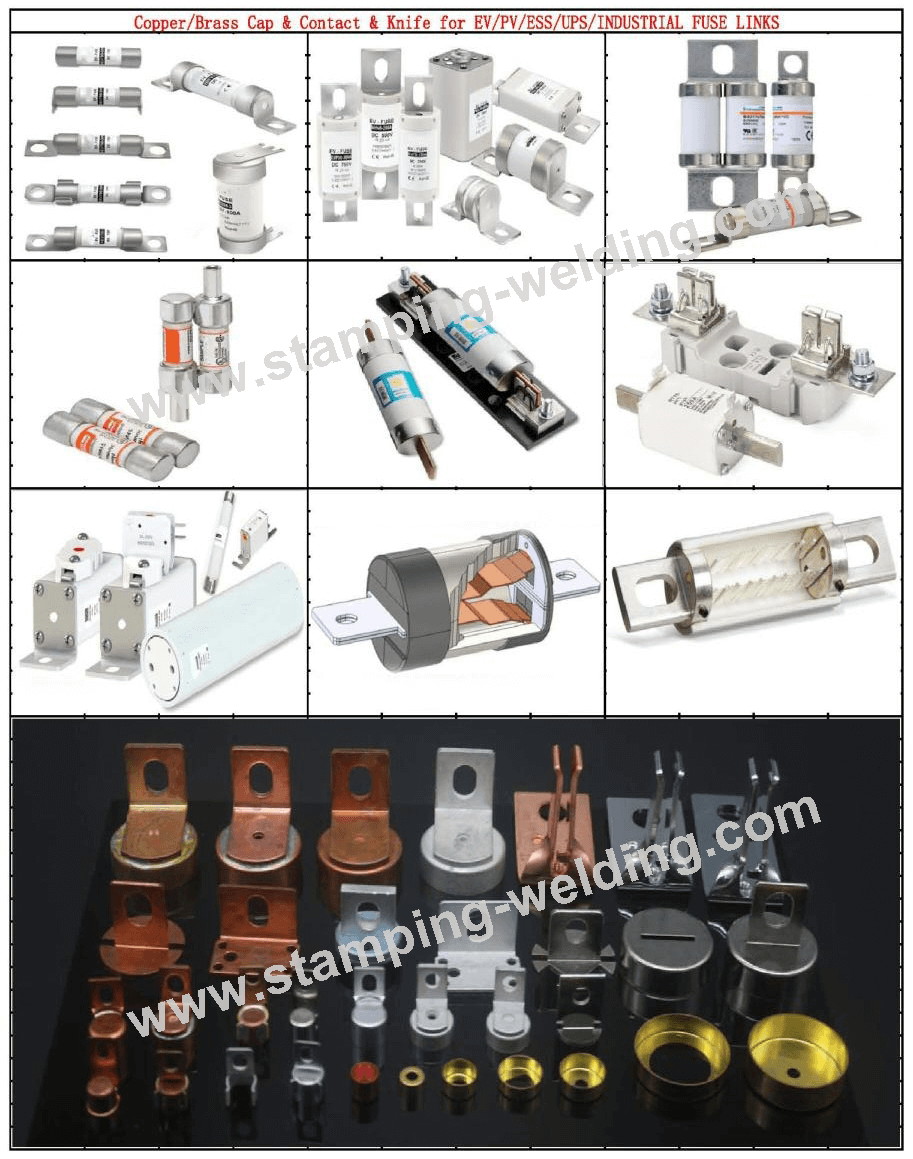

1-Products Name: Eaton Fuse Cap and Contact Joined by Tin Brazing

2-Base Material:

(1)Red Copper Stamping Parts:99.99% Copper T2Y2(SECu/C1100) ,%IACS≥97,HV:80~110s;

(2)Brass Stamping Parts:65% Brass H65(CuZn36/C2700),tensile strengthσb MPa≥440

3-Surface Treatments:

(1)Silver plating

(2)Bright tin plating

(3)Lead-free fog tin plating

(4)Nickel plating

(5)Ultrasonic cleaning

4-Free Samples:10-50pcs is allowed

5-Lead Time:Orders 7-10days,Samples 20-25days(including the tooling/die production of Copper Stamped Part);

6-Packing: Plastic inside and carton/pallet outside

7-Certifications: ISO9001,IATF16949,RoHS,REACH,etc.

8-Production Capacity: 50,000,000 pcs/month

9-Applications:PV Fuse,EV Fuse,PDU Fuse,Energy Storage Fuse,UPS DC Links,NH Fuse,BS Fuse,Fast Fuse,etc.

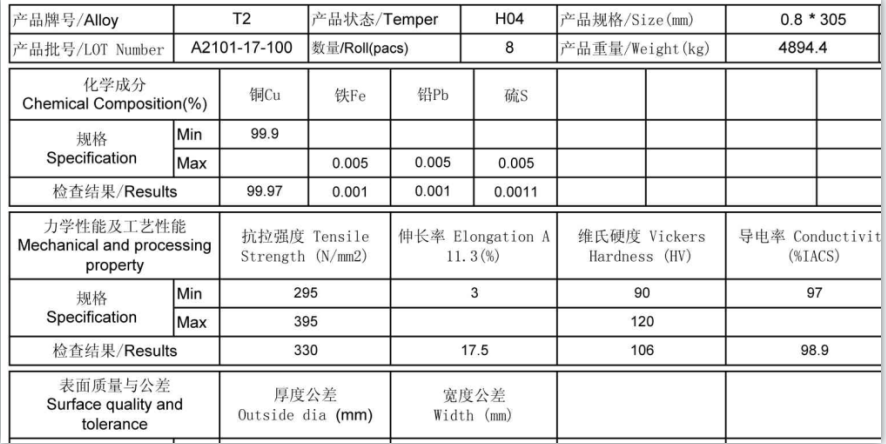

The base material of Fuse Contact T2Y2 Red Copper characteristics

National standard copper belt T2Y2 (Japanese standard copper model C1100) is also known as pure copper, copper purity ≥99.9%. The red copper of Fuse Terminal Contact has good thermal conductivity, processability, ductility, corrosion resistance and weather resistance. Copper Contact Terminal can be used in fuse link, capacitors, relays, contactors, circuit breakers and other electrical industries.

1. T2Y2 copper of the Fuse Terminal has good electrical conductivity, thermal conductivity, corrosion resistance and processing properties, and can be welded and brazed.

2. The red copper of Fuse L-type Termial contains less impurities that reduce electrical and thermal conductivity. The electrical conductivity and thermal conductivity for red copper of Securing Lug (Fixing Slot) are second only to silver, and are widely used in the production of electrical and thermal conductivity equipment and chemical industries.

3. Red copper of Copper Securing Lug (Fixing Slot) has good weldability. Xiamen China Apollo selects high-quality T2Y2 copper to produce copper fuse terminals, which can be processed into various semi-finished products and finished products Fuse Contact by cold and thermoplastic processing.

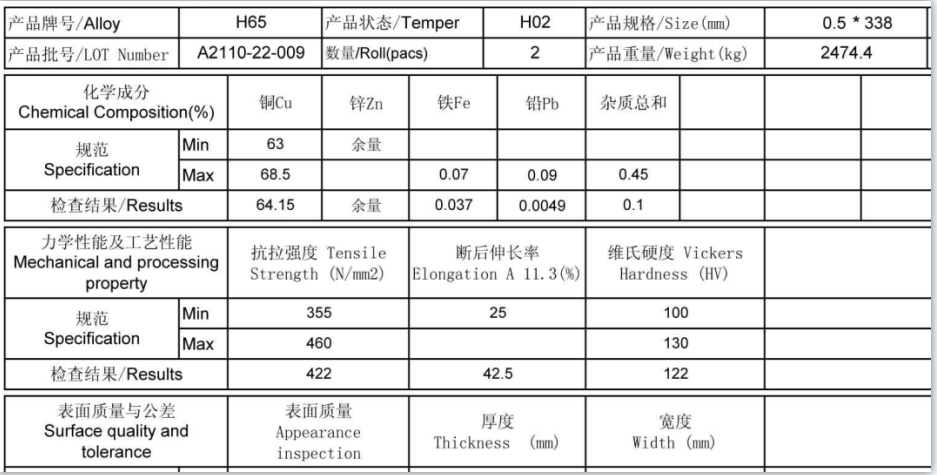

Material properties of Fuse End Caps Brass material

The performance of H65 Brass Inner Cap is between H68 and H62, the price is cheaper than H68, and it also has higher strength and plasticity, Brass Inner End Cap can well withstand cold and hot pressure processing, and has a tendency to corrosion cracking.Mainly used in the production of EV Fuse Brass Inner Outer Cap,PV Fuse Outer Brass Cap, Nickel Plated Brass End Caps,mainly used as electrical, thermal, corrosion-resistant equipment.

1.Brass of Fuse Inner Cap has very good plasticity and high strength, good machinability, easy welding, and general corrosion stability.

2.Brass of Brass End Cap has high strength and plasticity, can well withstand cold and hot pressure processing, and has a tendency to corrosion cracking.

3.H65 brass of Fuse End Caps has good mechanical properties and wear resistance, and can be used to manufacture precision instruments and Fuse Contact parts.

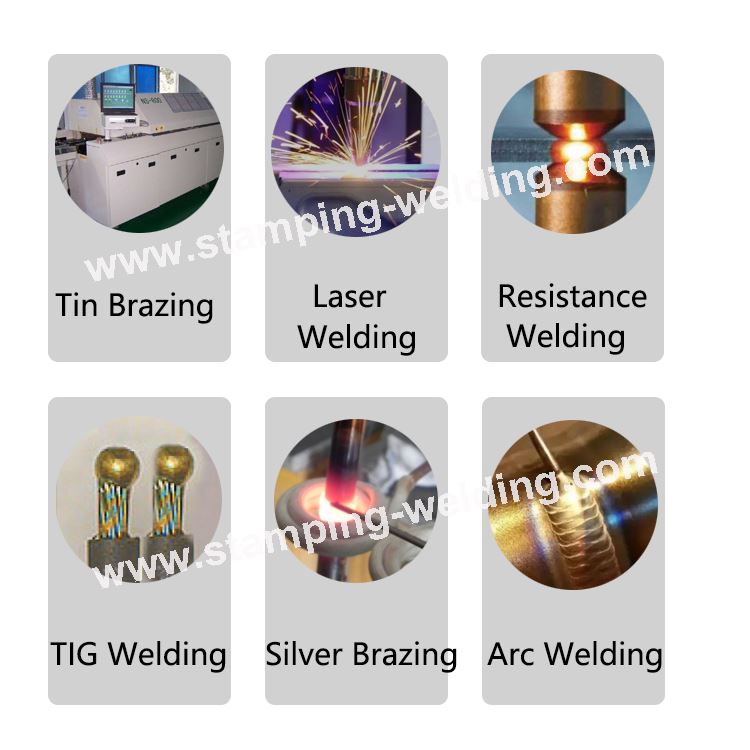

Characteristics of new energy Fuse Copper Contact and Outer Cap brazing

Brazing Fuse Copper Contact and Brass Outer Cap refers to a welding method in which the filler metal and the weldment below the melting point of the weldment are heated to the melting temperature of the filler metal at the same time, and then the liquid filler metal is used to fill the gap of the Fuse Copper Terminal and Brass Cap to connect the metals. During Fuse Contact Cap brazing, the oxide film and oil stains on the contact surface of the base metal should be removed first, so that the capillary can play a role after the brazing filler metal is melted and increase the wettability and capillary fluidity of the brazing filler metal. According to the different melting points of the solder, brazing is divided into brazing and soldering.

Brazing process of the Fuse Copper Contact and Brass Fuse Cap: The workpieces Fuse Copper Contact Cap that have been cleaned on the surface are assembled together in a lap joint pattern, and the solder is placed near or between the Fuse Contact Copper and Cap Brass joint gaps. When the workpiece and the solder are heated to a temperature slightly higher than the melting point of the solder, the solder melts (the workpiece is not melted), and is sucked in by capillary action and fills the gap between the solid workpieces Fuse Link Contact and Inner End Cap. The liquid solder and the workpiece metal diffuse and dissolve with each other. A brazed joint is formed after condensation.

1.The surface of the joint Copper Cap and Fuse Terminal is smooth, the air tightness is good, the shape and size are stable, the structure and properties of the weldment do not change much, and the same or different metals and some non-metals can be connected. During brazing Fuse Contact and Outer End Cap, the whole workpiece can also be heated, and many welds can be welded at one time, which improves the productivity. However, the strength of brazing joints is low, and lap joints are mostly used, and the joint strength is improved by increasing the lap length; in addition, the preparation work before brazing Copper Contact and End Caps is relatively high.

2.In order to make the brazing part Fuse Copper Contact and Copper Cap firmly connected and enhance the adhesion of the brazing filler metal, flux should be used during brazing to remove oxides on the surface of the brazing filler metal and the weldment.

3.Brazing Copper End Caps and Contact uses an alloy with a lower melting point than the base metal as the brazing filler metal. When heated, the brazing filler metal is melted and filled and kept in the joint gap by wetting and capillary action, while the base metal is in a solid state, relying on liquid brazing filler metal and solid mother metal. The mutual diffusion between the materials forms a brazed joint. Brazing Fuse Copper Contact and Cap Copper has little effect on the physical and chemical properties of the base metal, less welding stress and deformation, and can weld dissimilar metals with large differences in performance, and can complete multiple welds at the same time.

Contact Information:

Mr.Terry Young (Sales Manager&Technology Engineer)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact&Contact Riveted Set&Contact Brazed Set&Screw Terminal Set&Metal Stamping for Relay&Switch&Contactor&Breaker&EV PV Fuse,ect!