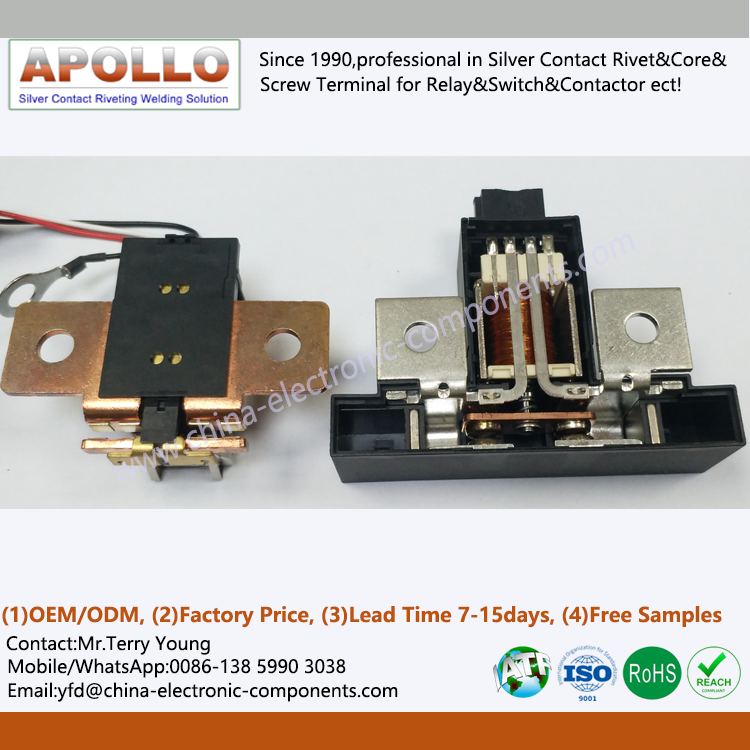

1-Products Name:Copper Terminal Ag-plated for HVDC Contactor

2-Base Material:T2Y2 Red Copper Stamping Parts

3-Silver Contacts:

(1)Without Contact

(2)Rivet Type Contact

(3)Round or Square Brazing Contact

4-Surface Plating:No plated or as require Silver-plated.

5-Free Samples:10-50pcs is allowed

6-Lead Time:Samples 20-25days(including the tooling/die production of Copper Stamped Part),Orders 7-10days

7-Application:EV PACK/PDU HVDC Relay,EV Charging Pile Contactor,New Energy Wind/PV Inverter Relay,Energy Storage Relay,UPS Relay.

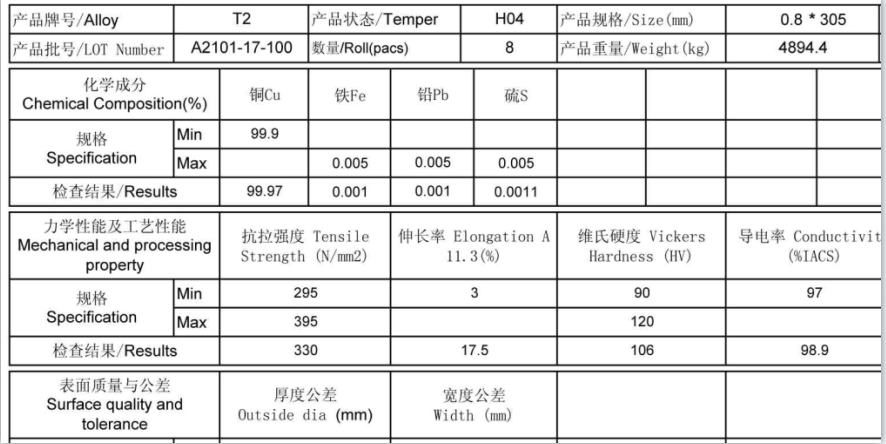

T2Y2 Red Copper Contact Terminal material characteristics:

1-Red Copper T2Y2 is Copper-silver alloy,Cu+Ag≥99.9%;

2-Semi-hard state,tensile strength 245~345(MPa),Elongation ≥8%,Vickers hardness 80~110Hv;

3-Conductivity ≥56Ms/m, resistance ≤0.0178x10-6 Ω.m,Density: 8.9 g/cm³;

4-Good electrical conductivity,thermal conductivity,corrosion resistance and processing properties, can be welded and brazed.

Copper Contact Terminal solutions for HVDC connectors for electric vehicles

While new energy vehicles bring innovative changes, there are also some pain points that have to be solved. Some new energy vehicles are slow to charge and have insufficient battery life, which reduces consumers' trust in new energy vehicles; in addition, some new energy vehicles cause fire accidents due to current overload during charging, posing potential safety hazards.For slow charging and insufficient battery life, fast charging is currently an effective solution. Fast charging requires high voltage and a larger current in a short period of time to reduce charging time. However, some fast charging piles may cause fire hazards when charging new energy vehicles due to high voltage and high current. In this case, it is particularly important to select materials Copper Contact Terminal for EV HVDC Contactor with excellent elasticity and conductivity to provide protection for fast charging piles and chargers.

In addition, as the number of interconnected devices in new energy vehicles has multiplied, power requirements have also risen. However, the design space of new energy vehicles is still limited. Therefore, in order to cope with this trend, the current application of new energy vehicle Copper Sheet Stamping for EV Relay is gradually turning to miniaturization.With the increase of voltage and current, it is necessary to further improve the conductivity of Copper Terminal Ag-plated for HVDC Contactor to reduce the temperature rise during the use of the connector. Miniaturization requires materials Copper Terminal Contact for EV Charging Pile Contactor with higher elastic modulus and strength to ensure connection reliability. It is difficult for traditional Fixed Copper Contact for EV Charging HVDC Contactor to meet the current development trend. To fully meet the requirements of high voltage, high current and miniaturization, it is necessary to put forward higher requirements for the comprehensive strength and conductivity of new energy vehicle connector materials.

Moving Copper Contact for EV HVDC Contactor has a strength of over 600MPa and a conductivity close to 60% IACS. It is one of the ideal materials for the new energy vehicle industry to respond to future trends.Silver Plated Copper Contact Movable for EV PDU HVDC Contactor has both good electrical conductivity, excellent mechanical properties, stress relaxation resistance and fatigue resistance, which can provide customers with higher performance redundancy design. When applied to the formation probe, the temperature rise of the material is extremely low. After 30,000 times of wear and tear, it can still maintain sufficient service performance. It is a very good material for the formation probe.In addition, Copper Contact Terminal for EV HVDC Relay Contactor has excellent electrical and thermal conductivity, and Copper Sheet Stamping for EV Relay is widely used as a new energy vehicle charging gun terminal, high-voltage wiring harness connector and vehicle relay terminal material, which contributes to the development of the new energy vehicle industry.

In addition, the demand for Copper Terminal Contact in the charging industry supporting electric vehicles is also very strong. The main power equipment of the charging station is power cable and transformer, in addition to circuit breakers, fuses, various switches, connectors, etc.; the main Copper Terminal Contact of charging piles include charging cables, charger modules, connectors and various switches Wait.

Metal Custom Copper Stamping process characteristics:

(1) Copper Stamping is a processing method with high production efficiency and low material consumption. The stamping process is suitable for the production of larger batches of parts, which is easy to realize mechanization and automation, and has high production efficiency. At the same time,Copper Sheet Stamping production can not only strive to achieve less waste and no waste production, but also has margins in some cases. The leftover material can also be fully utilized.

(2) The operation process is convenient and does not require the operator to have a higher level of skill.

(3) The Electrical Copper Stamping Parts generally do not need to be mechanically processed, and have high dimensional accuracy.

(4) Metal Stamping Parts Electric Copper have better interchangeability. Stability of stamping processing is better, the same batch of stamping parts. Can be used interchangeably without affecting assembly and product performance.

(5) Since the Copper Stamping Parts are made of plates, its surface quality is better, which provides convenient conditions for subsequent surface treatment processes (such as electroplating and painting).

(6) Copper Strip Stamping can obtain parts with high strength, high rigidity and light weight.

(7) The cost of Red Copper Stamping Parts produced in batches with molds is low.

(8) Precision Copper Stamping Parts can produce parts with complex shapes that are difficult to process with other metal processing methods.

Contact Information:

Mr.Terry Young (Sales Manager&Technology Engineer)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor&Breaker ect Riveting&Welding solutions !