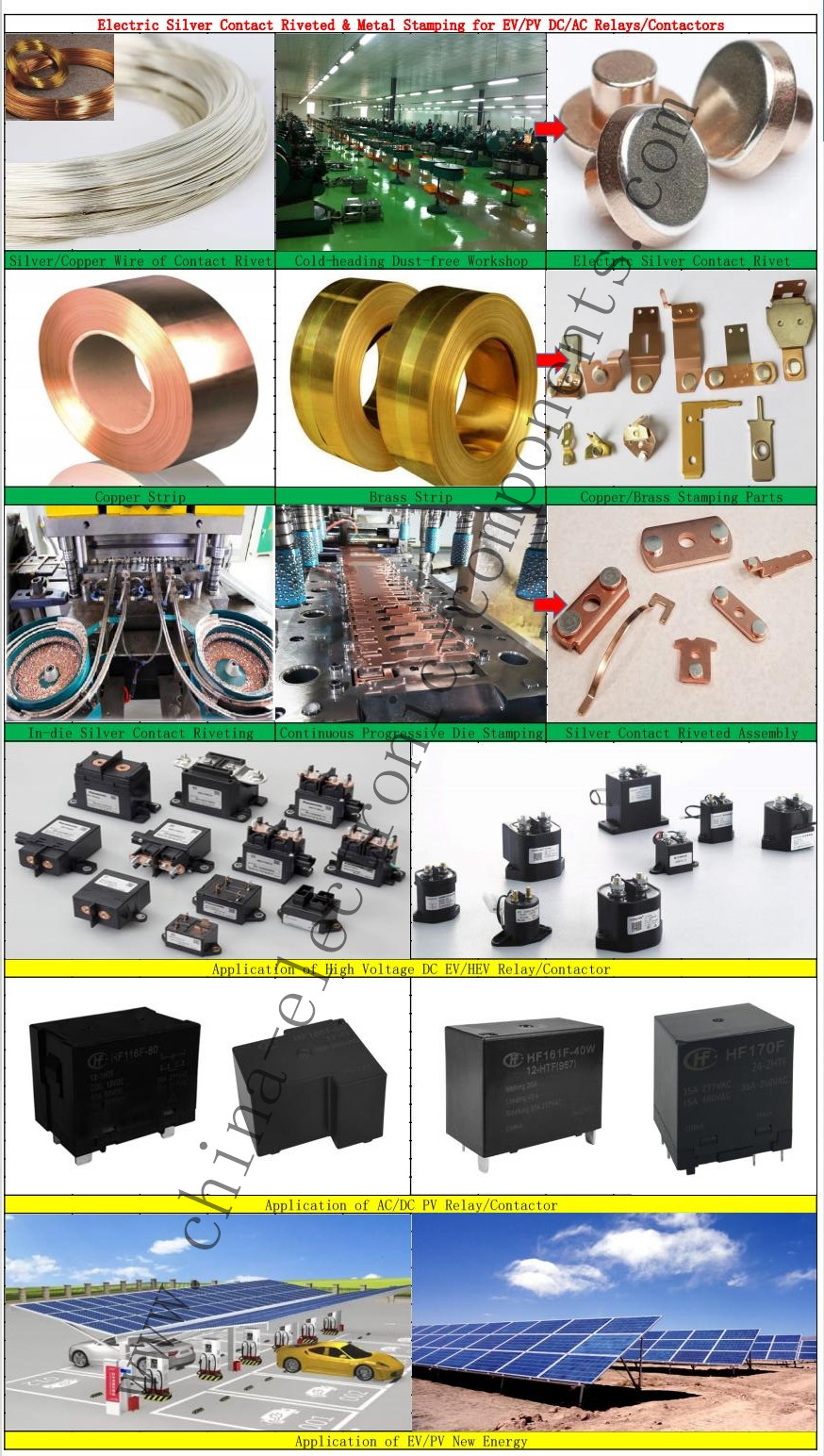

1-Products Name:Copper Stamping Terminal for EV Charging Relay

2-Base Material: Red Copper Stamping Parts

3-Riveted Silver Contacts: PAg,FAg,AgNi,AgSnO2,AgSnO2ln2O3,AgCdO,AgZnO,etc

4-Surface Plating:No plated or as require Silver-plated.

5-Free Samples:10-50pcs is allowed

6-Lead Time:Samples 20-25days(including the tooling/die production of Copper Stamped Part),Orders 7-10days

12-Application:EV PACK/PDU HVDC Relay,EV Charging Pile Contactor,New Energy Wind/PV Inverter Relay,Energy Storage Relay,UPS Relay.

Our products Electric Silver Contact Features:

1-The contact resistance is low and stable

2-Good welding resistance and thorough opening and closing

3-Good conductivity

4-Good abrasion resistance,the contact surface not changed

5-Not easy to oxidize for a long time

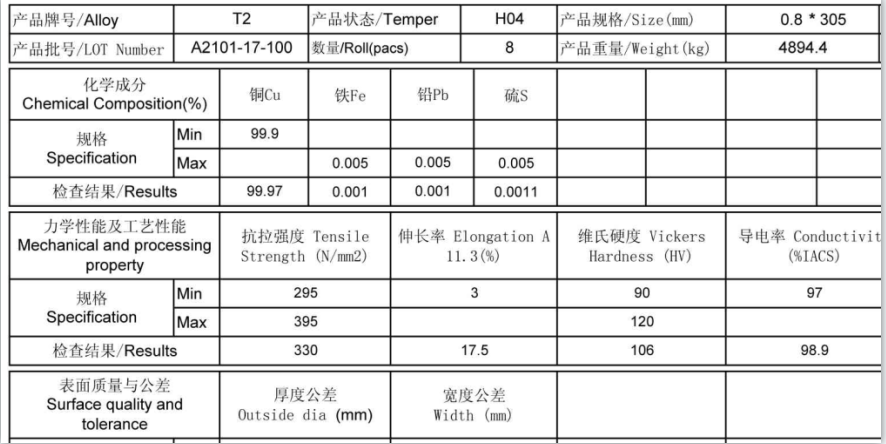

Red Copper T2Y2 Strip or Plate material characteristics:

1-Red Copper T2Y2 is Copper-silver alloy,Cu+Ag≥99.9%;

2-Semi-hard state,tensile strength 245~345(MPa),Elongation ≥8%,Vickers hardness 80~110Hv;

3-Conductivity ≥56Ms/m, resistance ≤0.0178x10-6 Ω.m,Density: 8.9 g/cm³;

4-Good electrical conductivity,thermal conductivity,corrosion resistance and processing properties, can be welded and brazed.

Precautions for the use of high-voltage composite silver contacts

1. The rated values in the composite silver contact parameters are the values under resistive load. When using an inductive load with L/R>1ms, please connect a surge current protection device to the inductive load in parallel. If no measures are taken, the electrical life may be reduced, and the on-off failure may occur. Please consider sufficient margin space in the design of composite silver contacts.

2. This composite silver contact high-voltage switchgear may cause high temperature failure when it exceeds the service life and load capacity specified in this specification. A protection circuit that can cut off the load in an emergency should be used. To ensure safety, Replace parts regularly.

3. ADH series energy-saving products have a built-in energy-saving board. The coil will automatically switch after being turned on for 0.1-0.2 seconds. Repeated on-off operations of <0.2s will cause composite silver contact failures, please pay attention!

4. The Electrical contact of the ADH series product is in a sealed cavity, and the cavity is filled with gas. The leakage rate of the gas in the cavity is proportional to the temperature of the cavity (the ambient temperature and the temperature rise generated by the contact energization). Please ensure that the ambient temperature is- Within 40℃~+85.

5. Avoid using it near strong magnetic fields (around transformers and magnets) and near heating objects.

6. When installing, make sure that the main power cord is closest to the leading end of the composite silver contact, and then install it firmly in the order of flat washers, spring washers, and nuts, or use self-locking nuts directly. Incorrect connection sequence may cause severe overheating and cause the insulation of the connecting cable to melt.

7. Please control the screw tightening torque of each part within the following specified range. Exceeding the range may cause damage to the sealed cavity and thread damage. In addition, the installation direction is not restricted.

The process of In-die Riveting Silver Contacts for PV EV Relays

Silver contact riveting terminal riveting is a common mechanical connection method, which is more commonly used in metal secondary processing such as stamping, and spin riveting is generally used to connect electronic conductive Bimetal Contact for PhotoVoltaic PV Electromagnetic Relay and reeds. Traditional spin riveting is generally completed by the operator after manual assembly on the spin riveting machine. This process not only has low production efficiency, but also has unstable spin riveting quality.

The process steps of the riveting of the Static Silver Contact AC Side Photovoltaic PV Relay riveting terminal in the mold: Moving Contact for PCB Photovoltaic PV Relay progressive die punching brake reed → moving reed pickling → riveting Fixed Contact for EV Relay → bending of the Moving Spring Contact Assembly. Due to the large production volume of this product, in order to improve Production efficiency, stable product quality, and reduce production costs. The new process route formulated is: progressive die with material to produce moving reed strip → strip cleaning → strip riveting State Contact Rivet for PV AC Circuit Relay and forming.

The technical requirements for the riveting of in-die Flat Silver Contacts for PV Power Relay riveting terminals: to achieve good in-mold riveting, the machining accuracy of mold parts is extremely high, oil cutting, PG, JG and other high-precision processing equipment are required; at the same time, the vibration plate and the mold are required. and the requirements for the gap and segment difference of the riveted Flat Bimetallic Rivet for DC Circuit Photovoltaic Relay and shrapnel are very high.

Contact Information:

Mr.Terry Young (Sales Manager&Technology Engineer)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor&Breaker ect Riveting&Welding solutions !