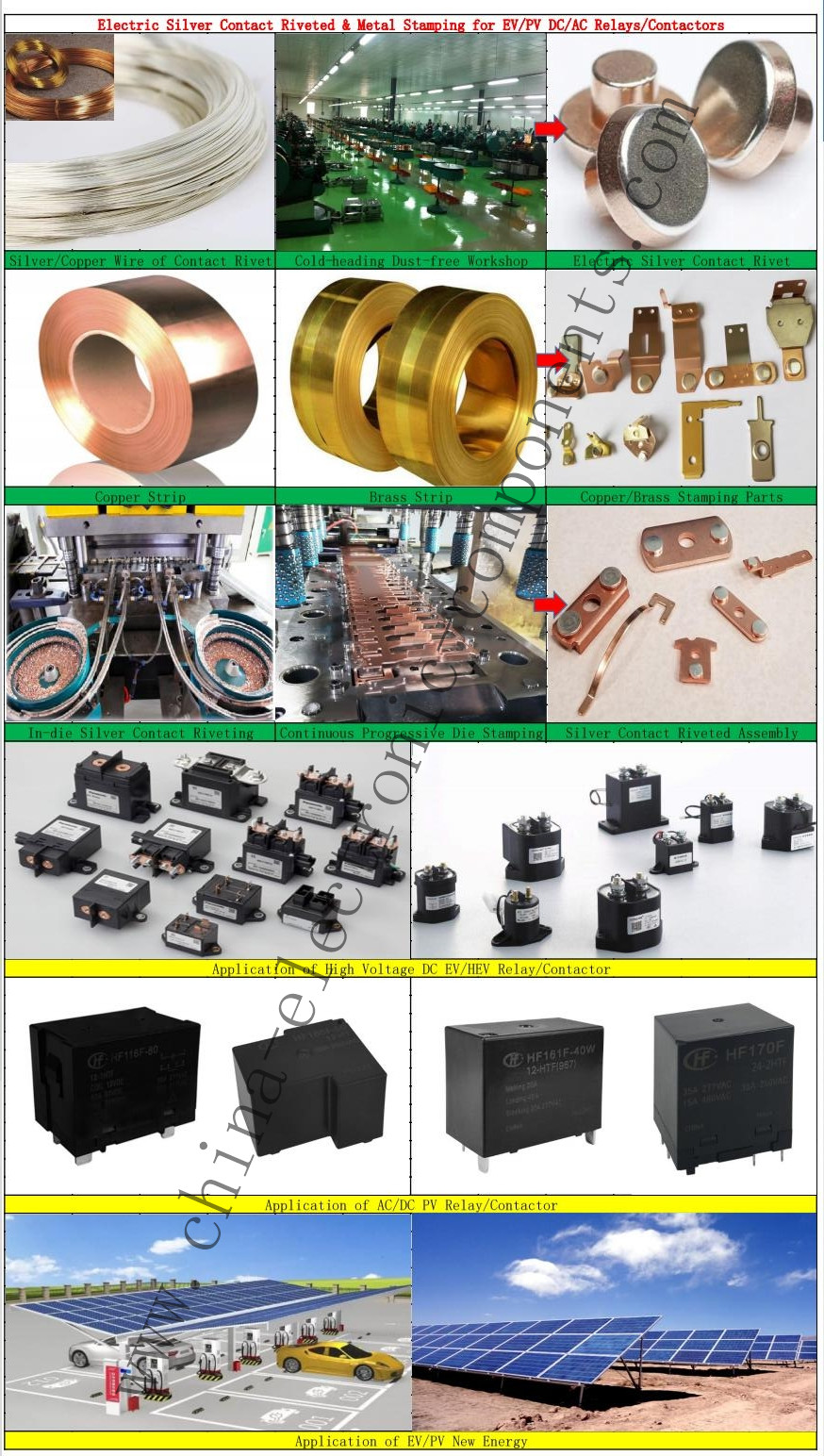

1-Products Name:Silver Contact Copper Stainless Steel Riveted Assembly for PV Relay

2-Base Material: Red Copper/Alloy Copper/Beryllium Copper/Stainless Steel Stamping Parts

3-Riveted Silver Contacts: PAg,FAg,AgNi,AgSnO2,AgSnO2ln2O3,AgCdO,AgZnO,etc

4-Surface Plating:No plated or as require Silver-plated.

5-Free Samples:10-50pcs is allowed

6-Lead Time:Samples 20-25days,Orders 7-10days(including the tooling/die production of Copper Stamped Part)

12-Application:EV PACK/PDU HVDC Relay,EV Charging Pile Contactor,New Energy Wind/PV Inverter Relay,Energy Storage Relay,UPS Relay.

Our products Electric Silver Contact Features:

1-The contact resistance is low and stable

2-Good welding resistance and thorough opening and closing

3-Good conductivity

4-Good abrasion resistance,the contact surface not changed

5-Not easy to oxidize for a long time

Introduction to the application of DC/AC Relay in the field of new energy

With people's awareness of the importance of environmental protection and the over-exploitation of the earth's traditional energy sources (oil and natural gas), the development and utilization of new energy sources has become more and more urgent and important.

At present, the technology development of electric energy and solar energy in the world is becoming more and more mature, and the fields of application are also becoming wider and wider. For example, new energy vehicles, solar thermal power generation, solar street lights, etc., the application of Bimetal Contact for PhotoVoltaic PV Electromagnetic Relay in the field of new energy is introduced:

(1) New energy electric vehicle

Including charging piles, charging guns, BMS systems and other products

(2) Solar thermal power generation

Heliostat motor control

(3) Solar photovoltaic power generation

Solar panels clean sand, frost, snow, etc.

The process of In-die Riveting Silver Contacts for PV Relay

Silver contact riveting terminal riveting is a common mechanical connection method, which is more commonly used in metal secondary processing such as stamping, and spin riveting is generally used to connect electronic conductive Bimetal Contact for PhotoVoltaic PV Electromagnetic Relay and reeds. Traditional spin riveting is generally completed by the operator after manual assembly on the spin riveting machine. This process not only has low production efficiency, but also has unstable spin riveting quality.

The process steps of the riveting of the Static Silver Contact AC Side Photovoltaic PV Relay riveting terminal in the mold: Moving Contact for PCB Photovoltaic PV Relay progressive die punching brake reed → moving reed pickling → riveting Movable Contact for Photovoltaic PV Inverter Relay → bending of the Moving Spring Contact Assembly. Due to the large production volume of this product, in order to improve Production efficiency, stable product quality, and reduce production costs. The new process route formulated is: progressive die with material to produce moving reed strip → strip cleaning → strip riveting State Contact Rivet for PV AC Circuit Relay and forming.

The technical requirements for the riveting of in-die Flat Silver Contacts for PV Power Relay riveting terminals: to achieve good in-mold riveting, the machining accuracy of mold parts is extremely high, oil cutting, PG, JG and other high-precision processing equipment are required; at the same time, the vibration plate and the mold are required. and the requirements for the gap and segment difference of the riveted Flat Bimetallic Rivet for DC Circuit Photovoltaic Relay and shrapnel are very high.

What is a high-power and high-insulation performance PV Relay for solar photovoltaic inverters ?

With the rapid development of the solar photovoltaic industry, higher requirements have also been put forward for the Electric Contacts for PV Relay used in solar photovoltaic inverters, especially for relay loads. According to market needs, it is necessary to develop a high-power relay whose load The voltage reaches 800Va.c., and the switching current needs to reach at least 90A. The Electrical Contacts for Solar Panel Relay used need to comply with relevant standards, but also set appropriate creepage distances and electrical clearances according to the actual use environment requirements (air pressure, pollution, etc.) of stability.

The existing Fixed Silver Contact for Solar Power Relay for solar photovoltaic inverters usually use a snap-on magnetic circuit. The Electrical Contacts for Solar DC Relay includes a base, a coil, an iron core, an armature, a yoke, a moving spring, a static spring and other components. The coil is mounted on the base, and the iron core is inserted into the wire. In the circle, the yoke is arranged at the coil, and the armature is matched at the knife edge of the yoke. When the coil is working, one end of the armature is attracted to the iron core and drives the moving contact of the moving spring to contact the static contact of the static spring. The existing Oxidized Electrical Contact for Solar Relay structure has a low switching load voltage and cannot meet the requirements of high-power switching capability. On the other hand,Electrical Contacts for Solar Switch cannot directly meet the requirements of high insulation performance (high creepage distance), and its creepage distance cannot meet 800Va. c. Requirements under.

Contact Information:

Mr.Terry Young (Sales Manager&Technology Engineer)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor&Breaker ect Riveting&Welding solutions !