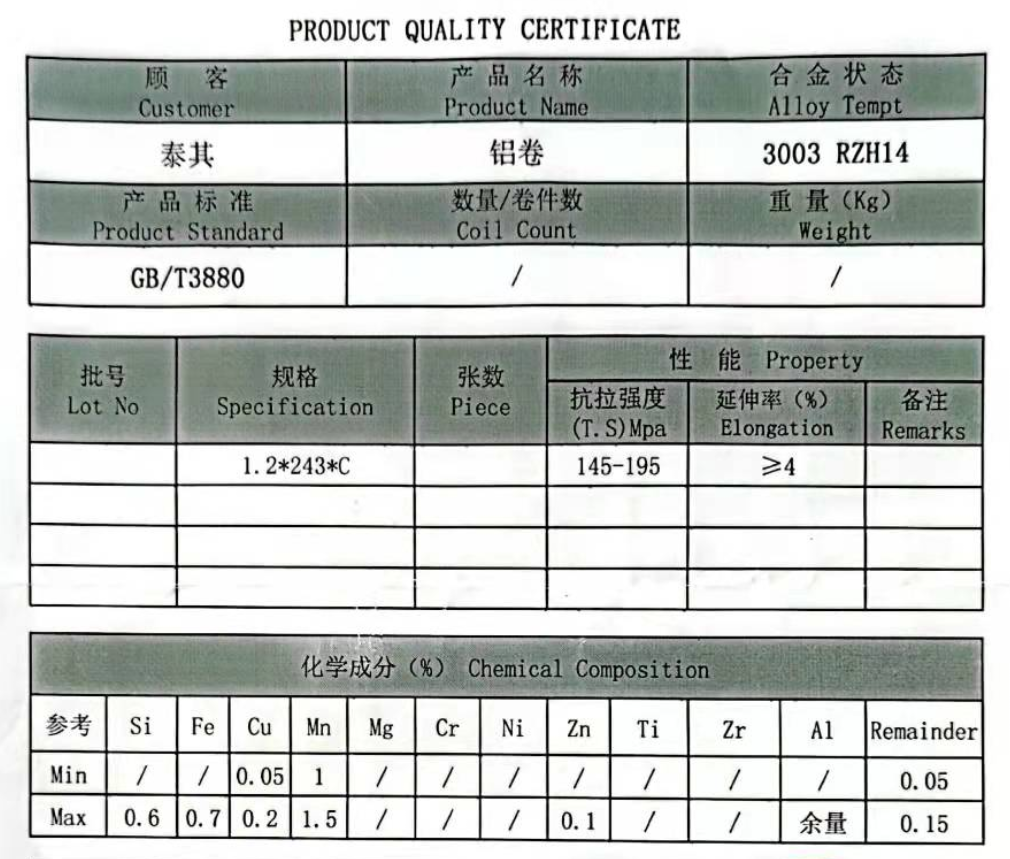

1-Base Material: 3003-H14 Aluminum Alloy (tensile strength≥140MPa)

2-Surface Plating:

(1)Ultrasonic cleaning;

(2)Anodizing.

3-OEM/ODM:Accepted,need your drawing

4-Free Samples:10-50pcs is allowed

5-Lead Time:Samples 10-20days,Orders 7-10days(including the tooling/die production)

6-Production Capacity:50,000,000 pcs/month

7-Packing:Inner blister packaging,Outer carton/pallet

8-Payment Item:T/T,L/C by USD/EUR/RMB

9-Quality Standard:ISO9000,IATF16949,RoHS,REACH

10-Application:Car Engine Starting,Valve-sealed Lead-acid Batteries,Open Tubular Lead-acid Batteries and Lithium Iron Phosphate Batteries etc for Electric Vehicles,Electric Trains,Electric Bicycles, Golf Carts and Solar Photovoltaic New Energy Storage.

Features of power lithium battery case:

1-The elastic coefficient is small, and the collision friction does not spark, and it performs the best in the automotive process.

2-No metal pollution, no toxicity, no volatile metals in the surface oxide layer.

3-Compared with other metal materials, it has low density and light weight.

4-Strong plasticity, good productivity, and good advantages for production.

5-It adopts two processes of hot and cold, and has strong corrosion resistance.

6-It has good casting performance, the content of aluminum is very high, and the reserves are abundant.

7-It has good ductility and can be used to make light alloys with many metal elements, and the material is of high quality.

8-Good surface treatment performance.

9-Lithium-ion Battery Aluminum Shell has stable chemical properties, non-magnetic, and can be recycled and reused. It is a benign and recyclable metal material.

10-Using high-grade and high-quality 100% pure aluminum ingot raw materials, without any waste addition, supplemented by high-efficiency pure refining, up to 70PPi fine filter plate filtration, it is the first material for environmental protection materials and high-end product quality requirements.

11-Fully meet the indicators specified in the alloy chemical composition and mechanical properties table.

12-Fully meet the requirements of JISH4040/4080/4100 standard.

The power lithium-ion battery is the power source that provides the power source for the tool, and mostly refers to the battery that provides power for electric vehicles, electric trains, electric bicycles, and golf carts. It differs mainly from starter batteries used for car engine starting. Valve-sealed lead-acid batteries, open tubular lead-acid batteries and lithium iron phosphate batteries are mostly used.

Power battery aluminum shell is a kind of shell product used to protect power battery in new energy vehicles.Power battery casing adopts aluminum profiles as the main material, and the power battery can be mainly used in the following industries:

1. Automobile and motorcycle industry

Mainly to provide electrical energy for the starting ignition of the engine and the use of on-board electronic equipment;

2. Industrial power system

Lithium Batteries Square Aluminum Casing is used for power transmission and transformation substations, providing closing current for power units, and providing backup power and communication power for public facilities;

3. Electric vehicle and electric bicycle industry

Replacing gasoline and diesel as the driving power source for electric vehicles or electric bicycles.

3003 aluminum plate has many advantages for new energy power battery shell

1-Good workability. The power battery aluminum shell (except the shell cover) of 3003 aluminum alloy can be drawn and formed at one time. Compared with the stainless steel shell, the welding process of the bottom of the box can be omitted.

2-Light weight. The quality of the battery box Power battery shell has a great influence on the quality of the entire battery module. The density of aluminum alloy is higher than that of traditional stainless steel. In order to reduce the weight, it is an inevitable choice to use 3003 aluminum alloy material to make the battery casing.

3-Good heat transfer. The power battery will generate heat when it works for a long time, and the Pack Aluminum Housing needs to have good heat dissipation.

4-Good corrosion resistance. 3003 aluminum plate belongs to aluminum-manganese series alloy. Due to the manganese alloy element, the product LiFePO4 soft pack Cell has excellent anti-rust properties, also known as anti-rust aluminum plate.

In view of the above advantages, many companies currently use 3003 aluminum plate as the power battery shell material.With the country's emphasis on energy conservation and emission reduction and breakthroughs in aluminum alloy body panel technology, especially the increase in the production of new energy vehicles, the aluminization rate of automobile bodies will gradually increase, and the demand for aluminum for New Energy Vehicle Aluminum Battery Case will also increase.

Application of power battery aluminum shell in new energy electric vehicle

There are four main types of power batteries used in new energy electric vehicles: lead-acid batteries, nickel-metal hydride batteries, nickel-cadmium batteries and lithium power batteries. From the current level, each has its own advantages, but from the perspective of future development trends, it is the world of lithium power batteries. Lithium power battery is a new type of high-energy battery successfully developed in the 20th century. Because of its advantages of high energy, high battery voltage, wide operating temperature range and long storage life, large-capacity lithium batteries have been tried in electric vehicles and will become the electric vehicle in the 21st century. One of the main power sources of automobiles.

The Aluminum Battery Case power battery is one of the core components of the new energy electric vehicle. Its packaging process is very important in the production process of the power battery. Good packaging determines the safety and life of the power battery. The selection of the optimal packaging process for the characteristics of the Aluminum Alloy Prismatic Battery Case material is particularly important for the safety and service life of the power battery.

The aluminum battery box is mainly used to protect the internal materials of the battery from damage. It is generally made of 3003 aluminum alloy material. This material lithium ion cell Aluminum shell has the advantages of easy processing, high temperature corrosion resistance, good heat transfer and electrical conductivity. Because the material is aluminum, it is also called. The Aluminum Li-ion cells of the 3003 power battery can be stretched at one time. Compared with the stainless steel shell, the welding process of the bottom of the box can be omitted. When welding, there will be no problems such as the deterioration of the quality of the weld due to the burning of metal elements.

The Aluminum LTO Prismatic Battery Cell For EV has the advantages of low density and soft material, and it is easy to stretch the battery shell as a whole. It has been used by many enterprises for power battery packaging. Aluminum alloys are much less dense than traditional stainless steel encapsulation materials. In order to increase the cruising range, new energy electric vehicles need a large number of lithium battery combination modules. Each module is composed of several battery boxes. In this way, the quality of each battery box has a great impact on the quality of the entire battery module. In order to reduce the quality of the battery, it is an inevitable choice to use LiFePo4 Prismatic Battery Aluminum Cells materials to make the power battery casing.

Contact Information:

Mr.Terry Young (Sales Manager&Technology Engineer)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor&Breaker ect Riveting&Welding solutions !